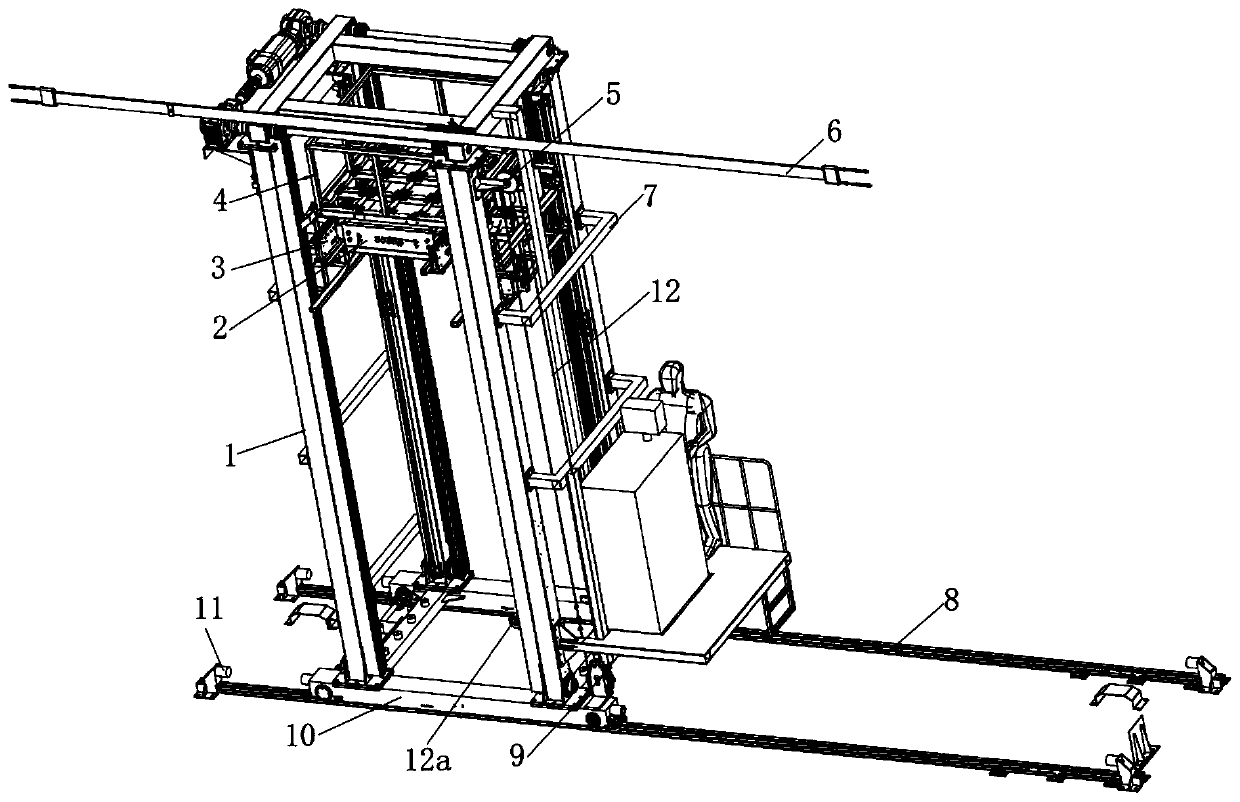

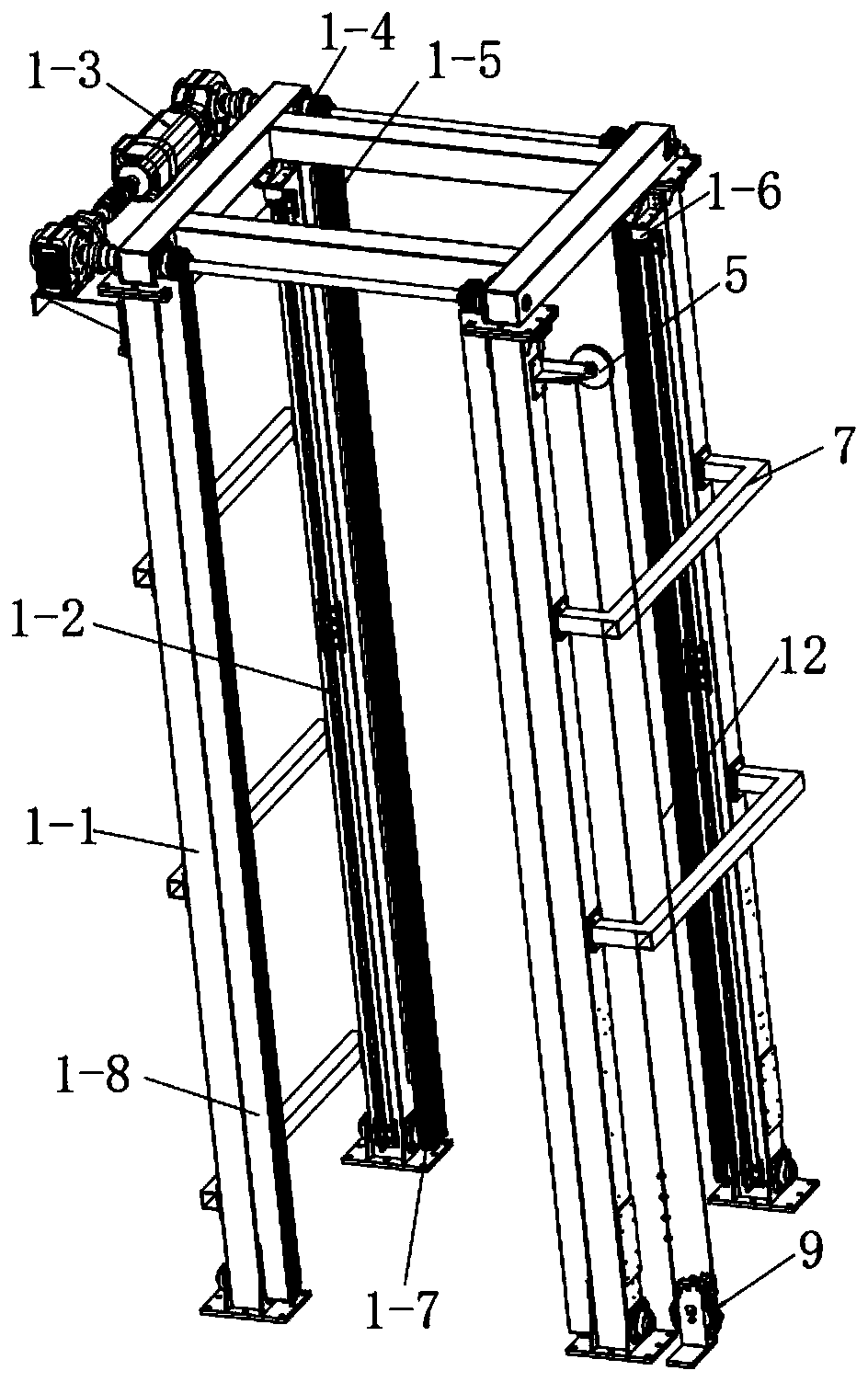

Hoisting system

A lifting system and lifting frame technology, applied in the direction of lifting devices, lifting frames, storage devices, etc., can solve the problems of restricting large-scale use and increasing costs, and achieve improved stability and safety, low cost, and strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention. The parts not mentioned in the present invention are all prior art.

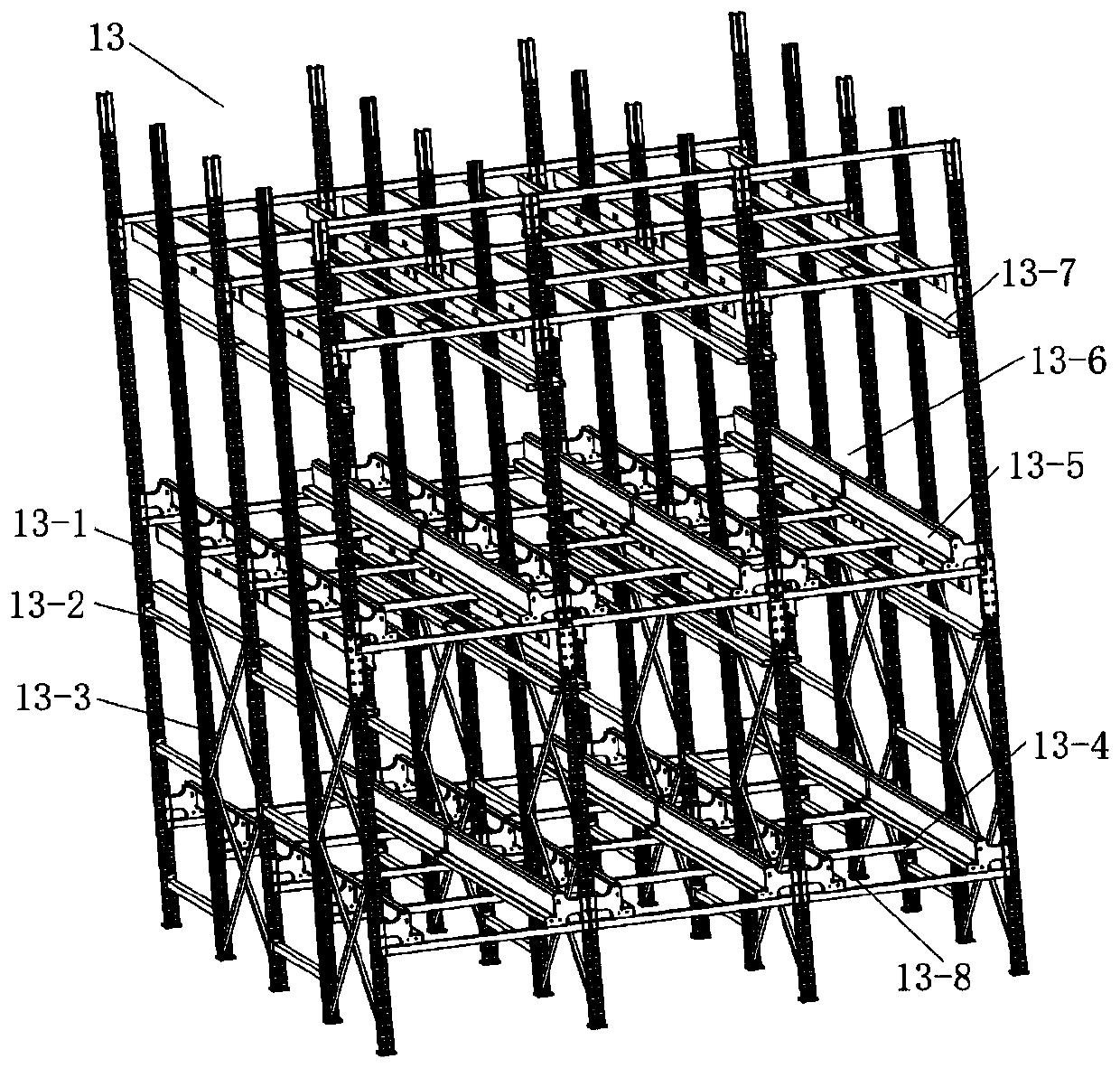

[0035] The plant cultivation container in the existing container cultivation technology mainly puts the cultivation substrate directly into the transparent root cultivation container, and then places a plurality of transparent root cultivation containers in the cultivation frame for shading cultivation as a whole. In order to optimize the use of space, it is becoming more and more popular to adopt multi-layer three-dimensional cultivation frames for placing cultivation frames....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com