Purification treatment method of manganese sulfate solution

A technology of manganese sulfate solution and treatment method, which is applied in the field of purification of manganese-containing solution, can solve the problem of high cost of purification treatment, and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

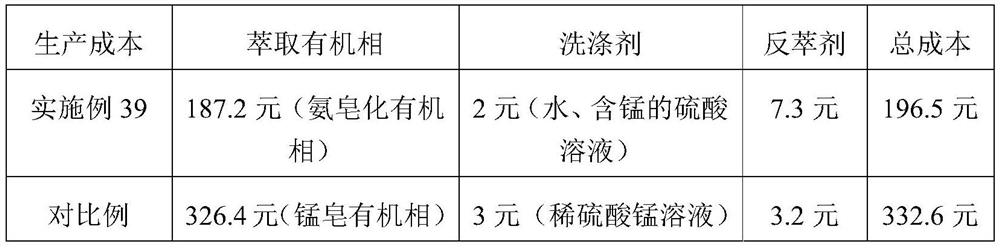

Examples

Embodiment 1

[0038] Preparation of saponified organic phase: take 1L of manganese sulfate solution, which contains: 30g / L Mn 2+ , 0.3g / L of Ca 2+ and 15g / L of Mg 2+ . Adjust the pH value of manganese sulfate solution to 3, control the volume ratio of P204 extractant and sulfonated kerosene to be 1:5, prepare 1L of organic extractant, and use ammonia water with a concentration of 8mol / L to saponify the organic extractant to form ammonia. Saponified organic phase, wherein the saponification rate is 70%.

[0039] Extraction: use the above-mentioned ammonia saponified organic relative manganese sulfate solution to carry out 5-stage countercurrent extraction to obtain a manganese-rich organic phase and a calcium-magnesium-containing aqueous phase. Wherein, the volume ratio of each level of saponified organic phase to manganese sulfate solution is 3:2, the temperature of each level of extraction is 25°C, and the time of each level of extraction is 5min.

[0040] The first washing: the above-...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that the manganese sulfate solution in Example 2 contains: 10g / L of Mn 2+ , 0.1g / L of Ca 2+ and 5g / L of Mg 2+ . The calculation shows that the removal rate of calcium ions in the manganese sulfate solution is 99.3%, and the removal rate of magnesium ions is 97.1%.

Embodiment 3

[0047] The difference between Example 3 and Example 1 is that the manganese sulfate solution in Example 3 contains: 50g / L of Mn 2+ , 0.5g / L of Ca 2+ and 20g / L of Mg 2+ . The calculation shows that the removal rate of calcium ions in the manganese sulfate solution is 99.3%, and the removal rate of magnesium ions is 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com