A secondary structure anti-seepage and anti-leakage construction method

A secondary structure and construction method technology, applied in building structure, building maintenance, construction, etc., can solve the problems of the connection force drop of the old and new concrete interface, the joint gap, seepage, etc., so as to prevent leakage and improve the resistance The effect of compressive strength and good impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] refer to figure 1 , is a secondary structure anti-seepage and anti-leakage construction method disclosed by the present invention, comprising the following specific steps:

[0065] S1. According to the requirements of the design drawings, mark the place where the primary structure needs to be constructed for the secondary structure, draw a line with chalk on the surface where the primary structure is about to be connected with the secondary structure, and circle the area where the primary structure is about to be connected with the secondary structure, forming Connection face ID.

[0066] S2. Gouging the surface of the structure at the area circled by the connection surface mark with a pick to form a connection groove, the length of the connection groove is consistent with the length of the area circled by the connection surface mark, and the width of the connection groove is the area circled by the connection surface mark 105% of the width, the depth of the connecting...

Embodiment 2-4

[0077] The difference with embodiment 1 is:

[0078] Each raw material addition (unit is Kg) is shown in Table 2 for details in the step S4:

[0079] Table 2

[0080] raw material Example 2 Example 3 Example 4 Portland cement 100 100 100 water 100 110 100 Superplasticizer 10 9 10 talcum powder 35 40 38 concrete expansion agent 7 8 7.5 fine aggregate 325 350 333 coarse aggregate 175 200 166

Embodiment 5-12

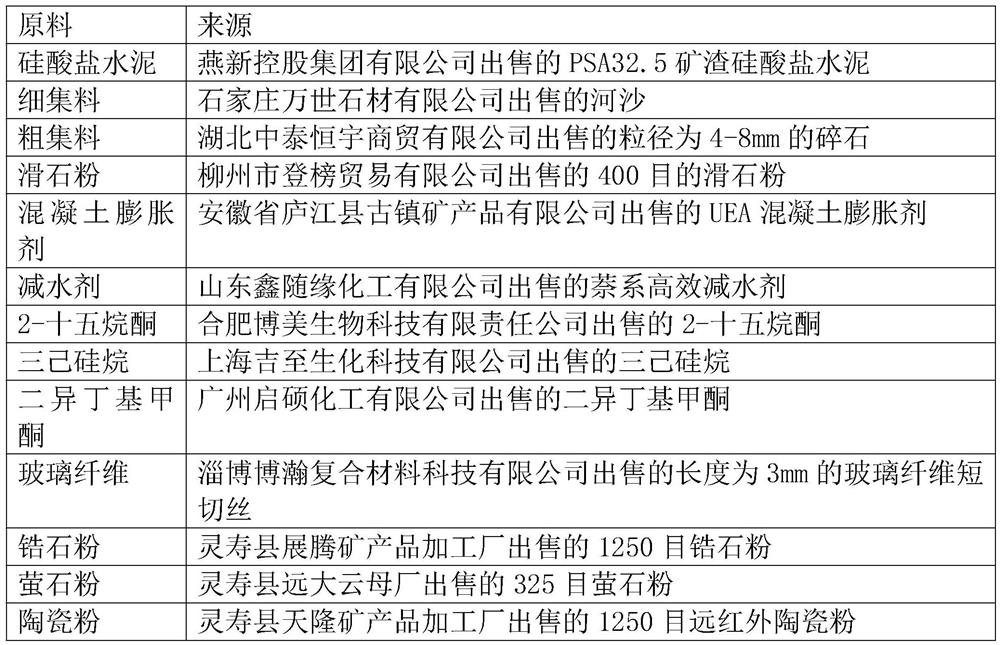

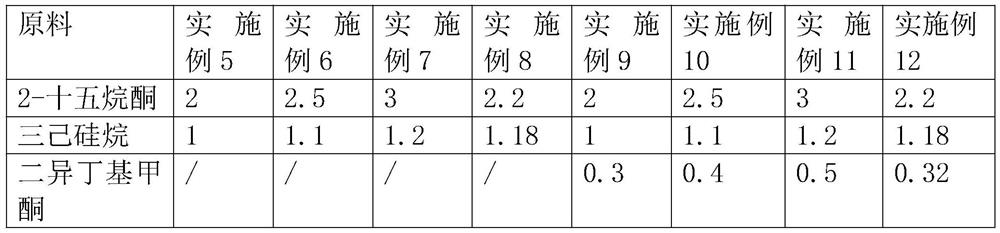

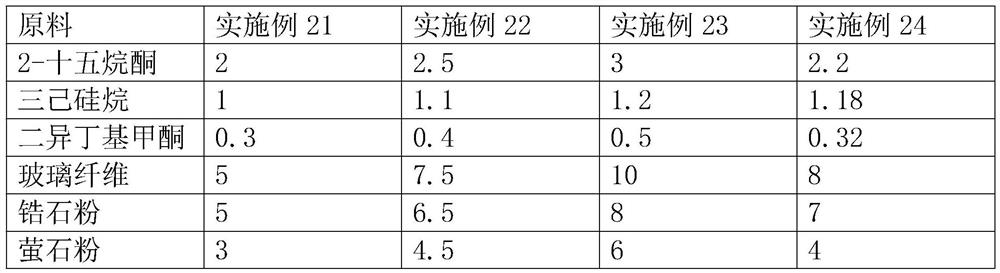

[0082] The difference with embodiment 4 is:

[0083] In step S42, one or more of 2-pentadecanone, trihexylsilane, and diisobutyl ketone is added, and the specific addition amount of each raw material (in Kg) is shown in Table 3

[0084] table 3

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com