Coal mine mining industry drilling machine

A mining and mechanical technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of inconvenient use and inconvenient adjustment, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

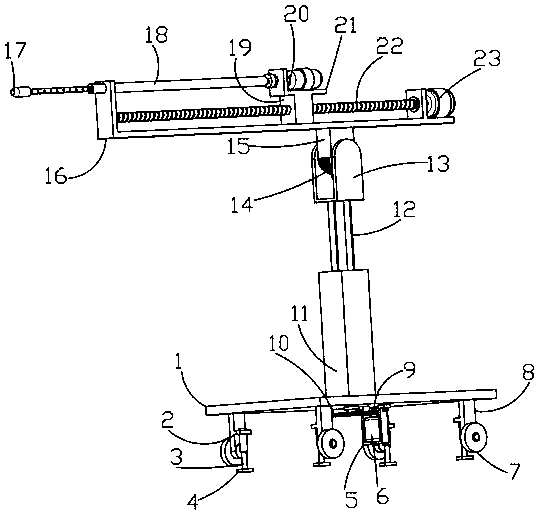

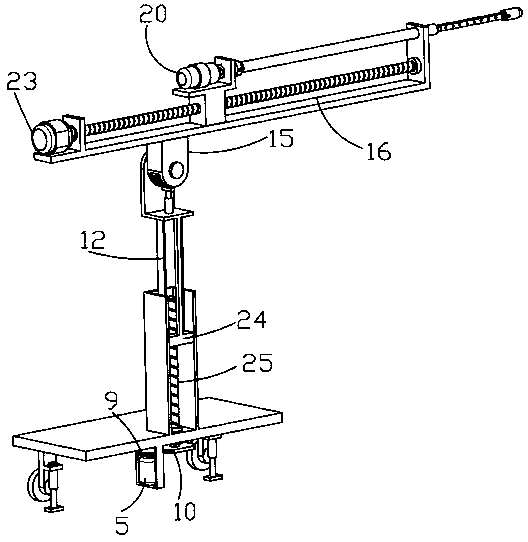

[0030] Such as Figure 1-5 A kind of coal mine mining drilling machinery shown, comprises bottom plate 1, first driving motor 6, second driving motor 20 and third driving motor 23, first driving motor 6, second driving motor 20 and third driving motor 23 are selected Servo motor, bottom plate 1 is fixedly connected with outrigger 8, outrigger 8 is rotatably connected with roller 7, outrigger 8 is connected with fixed structure, fixed structure includes horizontal plate 2, electric push rod 3 and rubber plate 4, horizontal plate 2 and support The legs 8 are fixedly connected, and the through hole of the horizontal plate 2 is fixedly connected with the electric push rod 3, and the telescopic end of the electric push rod 3 is fixedly connected with the rubber plate 4, and the electric push rod 3 of the fixed structure drives the rubber plate 4 to move downward. The rubber plate 4 is in contact with the ground to fix the position of the drilling rig equipment used in coal mine ope...

Embodiment 2

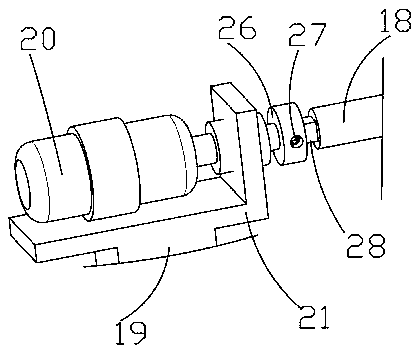

[0032] Such as Figure 1-5 The coal mining drilling machine shown includes a bottom plate 1, a first drive motor 6, a second drive motor 20 and a third drive motor 23. The bottom plate 1 is fixedly connected with a leg 8, and the leg 8 is rotatably connected with a roller 7. The outrigger 8 is connected with a fixed structure, the bottom plate 1 is rotatably connected with a first threaded rod 25 through a fixedly connected bearing, the bottom of the first threaded rod 25 is fixedly connected with a driven ring gear 10, the bottom plate 1 is fixedly connected with a mounting frame 5, and the mounting frame 5 is fixedly connected with the first driving motor 6, the output end of the first driving motor 6 is fixedly connected with the driving ring gear 9, the driving ring gear 9 is engaged with the driven ring gear 10, and the top of the base plate 1 is fixedly connected with a square sleeve plate 11, The square cover plate 11 is fitted and slidably connected with a square slide...

Embodiment 3

[0034] Such as Figure 1-5 The coal mining drilling machine shown includes a bottom plate 1, a first drive motor 6, a second drive motor 20 and a third drive motor 23. The bottom plate 1 is fixedly connected with a leg 8, and the leg 8 is rotatably connected with a roller 7. The outrigger 8 is connected with a fixed structure, the bottom plate 1 is rotatably connected with a first threaded rod 25 through a fixedly connected bearing, the bottom of the first threaded rod 25 is fixedly connected with a driven ring gear 10, the bottom plate 1 is fixedly connected with a mounting frame 5, and the mounting frame 5 is fixedly connected with the first driving motor 6, the output end of the first driving motor 6 is fixedly connected with the driving ring gear 9, the driving ring gear 9 is engaged with the driven ring gear 10, and the top of the base plate 1 is fixedly connected with a square sleeve plate 11, The square cover plate 11 is fitted and slidably connected with a square slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com