Heat exchanger

A technology of heat exchangers and heat exchange tubes, applied in heat exchange equipment, heat exchanger sealing devices, heat exchangers, etc., can solve the problems of rigid joint leakage, increase maintenance frequency and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Specific advantages of the invention

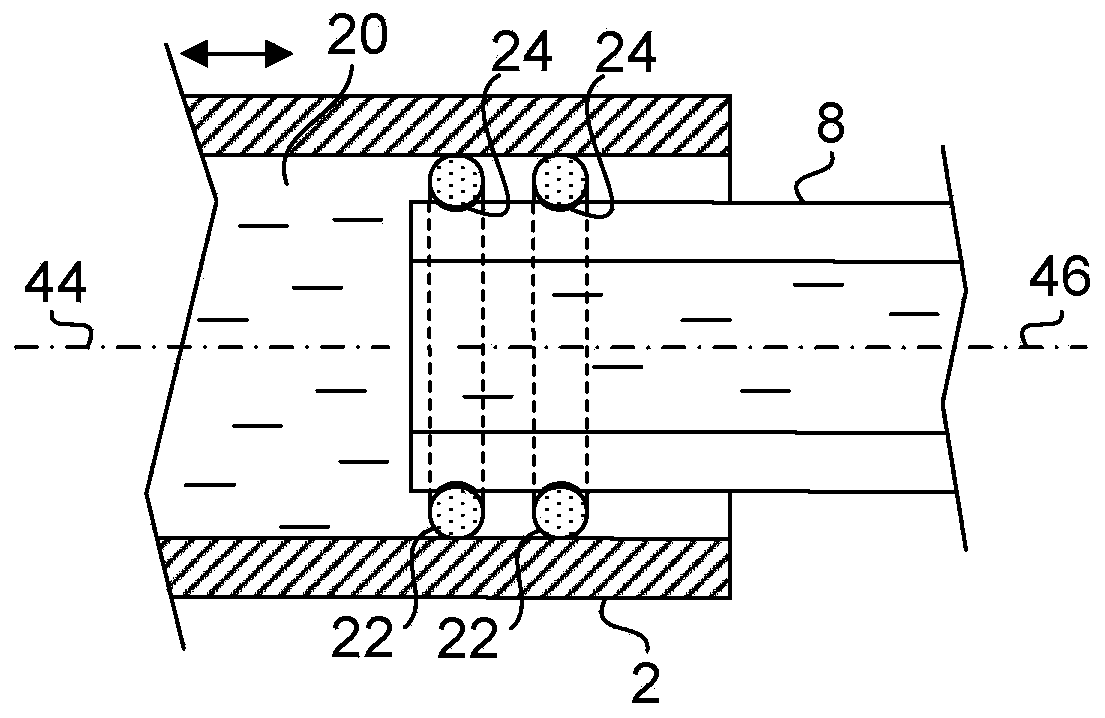

[0084] The present heat exchanger does not utilize conventional welded joints for fluid conductors, thereby eliminating the possibility of stress corrosion cracking associated with conventional welded joints. Every conventional welded joint is at risk of corrosion and leakage.

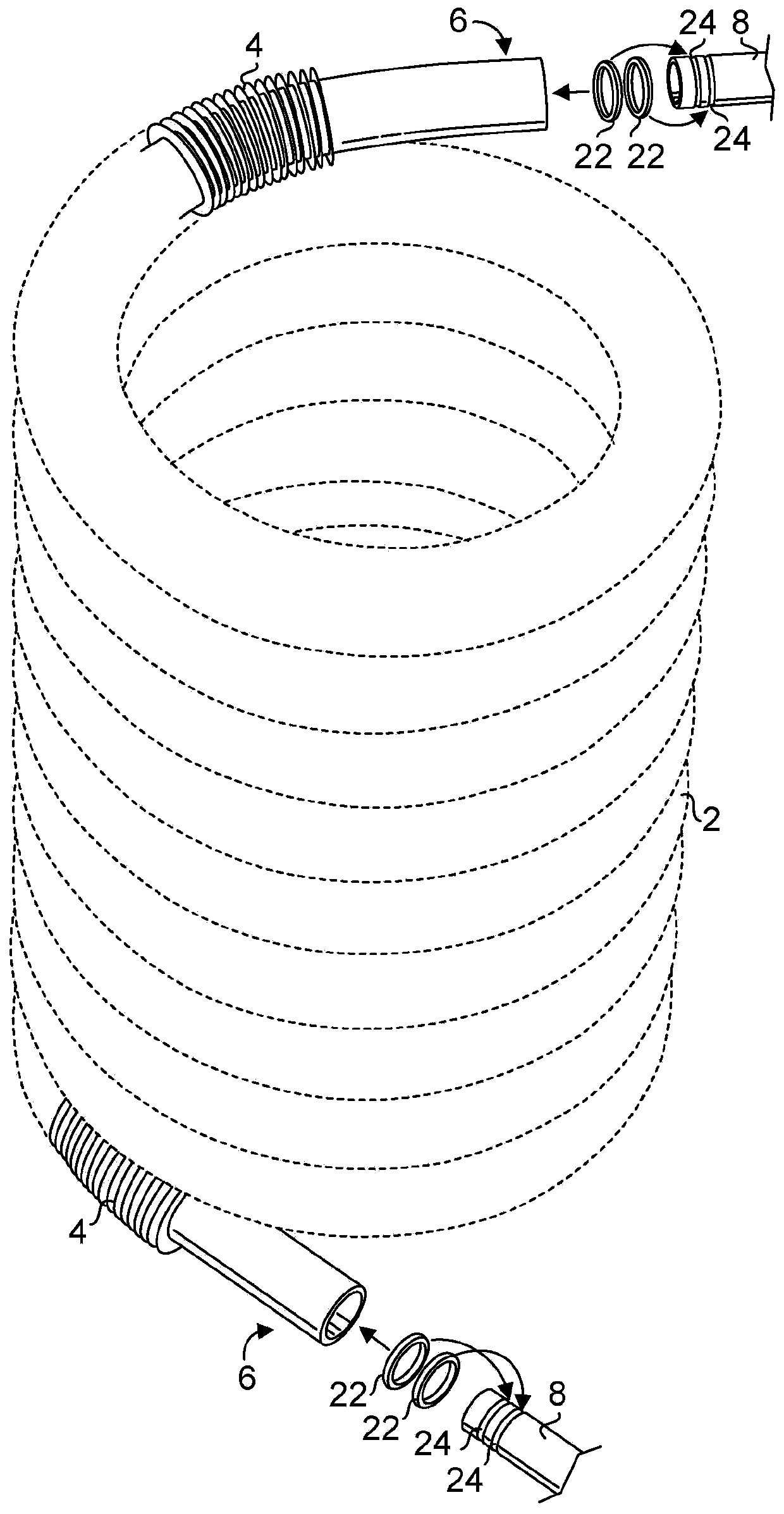

[0085] Since the present heat exchanger allows expansion and contraction of the heat exchange tubes, it is robust against thermal cycling.

[0086] The present heat exchanger includes a low mass of heat exchange tubes which allows for quick response to changing flow rates within the heat exchange tubes.

[0087] The present heat exchanger includes large channels, which allow high flow rates and minimize pressure drop and calcium carbonate fouling.

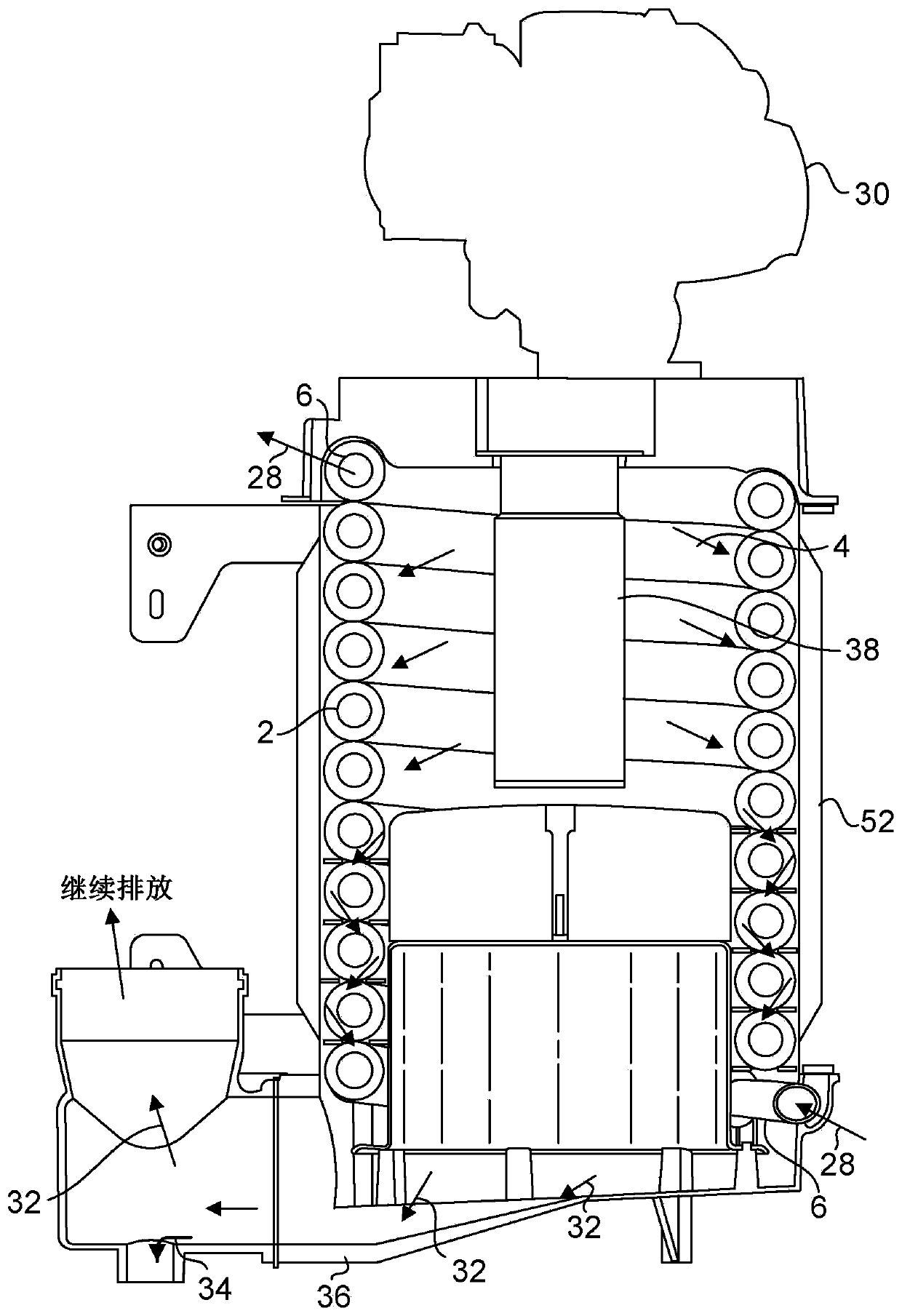

[0088] The present heat exchanger comprises: heat exchange tubes provided with a vertically disposed lumen; and a blower causing a flue flow that pushes condensate down and away from the heat exchange tubes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com