Calibration method for rotor-free vulcameter torque calibrator

A calibrator and vulcanization meter technology, which is applied in the calibration/testing of force/torque/power measuring instruments, instruments, scientific instruments, etc. It can solve problems such as calibration errors, easy aging of reference films, and poor calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

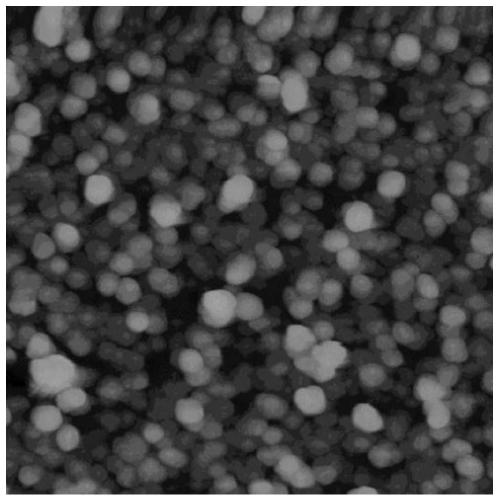

[0064] Place the snap-in sleeve in the plasma chamber, pump the chamber to a pressure of about 8 mTorr, and then inject helium gas at a rate of 20 sccm until the pressure is 60 mTorr, and then use RF to trigger the glow discharge, Wherein the frequency and power of RF are 13.56MHz and 300W, keep 5 minutes, then introduce the vapor of the monomer mixture (molar ratio is 1:3) of formula (I) and (II) in the chamber with the speed of 240mg / min , and switch the plasma to the pulsed plasma with the following characteristics: the peak power is 120W, the frequency is 50Hz, the duty cycle is 5%, and lasts for 45min, thereby forming a continuous and uniform polymer layer on the inner surface of the clamping sleeve, The thickness of the polymer layer was measured to be 2.10 μm.

Embodiment 2

[0066] Example 1 was repeated, except that the polymer monomer in Example 2 was only the monomer represented by formula (II). The plasma deposition was continued for 50 minutes, and the thickness of the polymer layer was measured to be 2.12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com