Process for preventing anodic oxidation deformation of plugging pin jacking plate of DaVinci test socket

A technology of anodizing and testing sockets, applied in contact manufacturing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of high requirements for hole position, large surface area, product deformation, etc., and increase the one-time pass rate , reduce or avoid changes, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

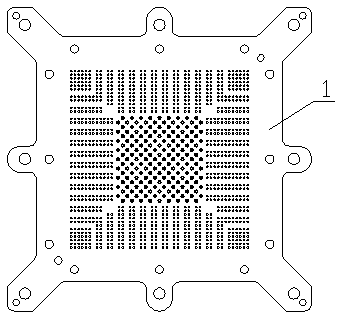

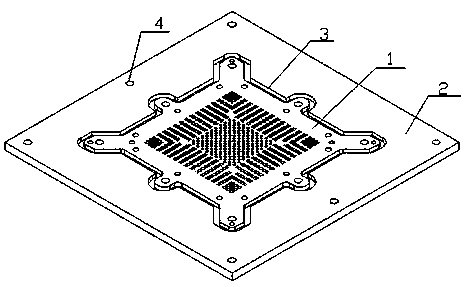

[0013] In the accompanying drawings: the anti-anodizing deformation process of the pin top plate of Da Vinci test socket, which is characterized in that it includes the following steps: Step 1, before anodizing, reserve a margin around the pin top plate 1 to form a reinforced frame 2; The length and width are increased by 30-40mm and thickness by 1-2mm on the basis of the maximum shape of the pin top plate 1; on the side that will be retained to form the product in the end, the depth is the same as the thickness of the final product processed along the product contour, and the width is 2-3mm groove 3; the outer side of the groove 3 and the margin in the thickness direction form a reinforced fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com