A split-type high-speed generator with position feedback

A split-type, generator technology, applied in electromechanical devices, machines/engines, jet propulsion devices, etc., can solve the problems of being unsuitable for light weight and volume, high price of air bearings, large volume, etc., to reduce volume and weight. , The effect of improving the smoothness of starting and improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

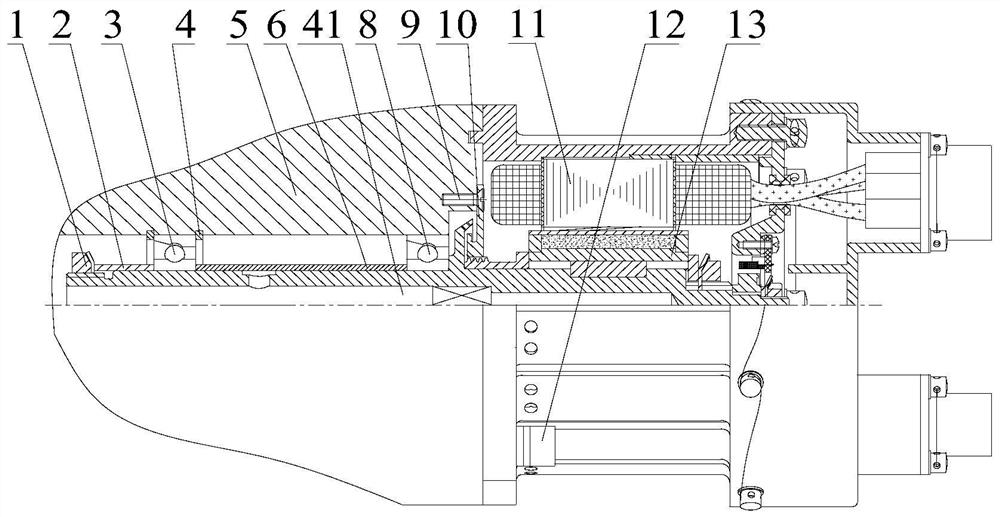

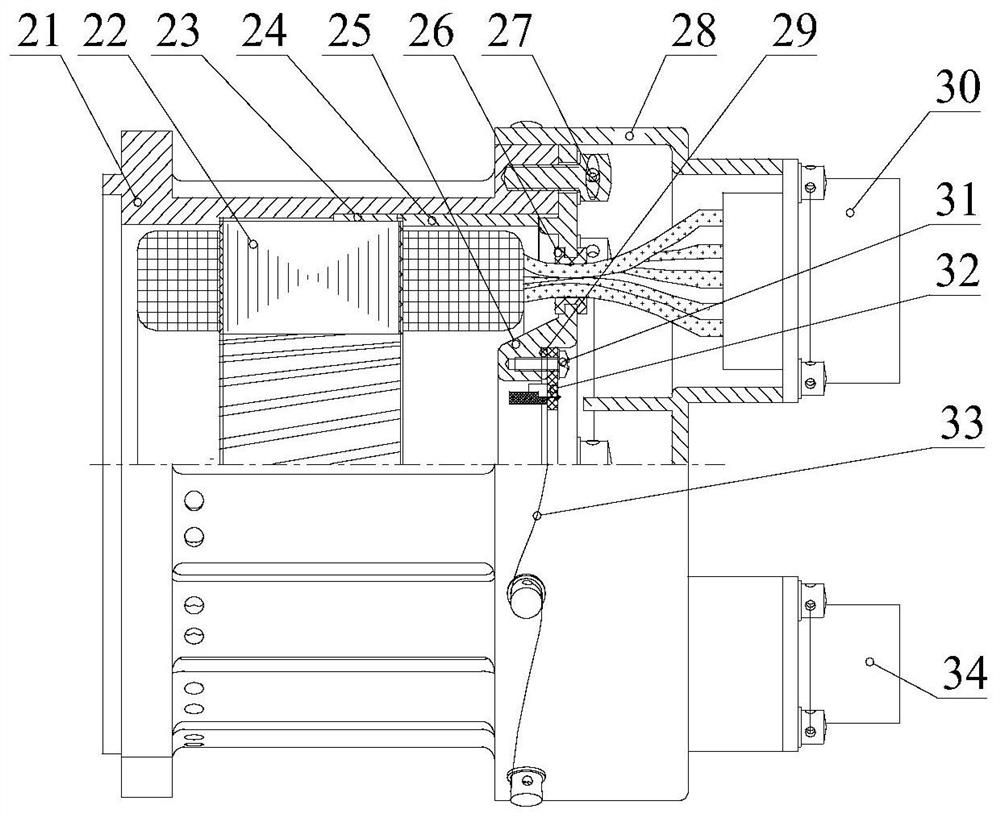

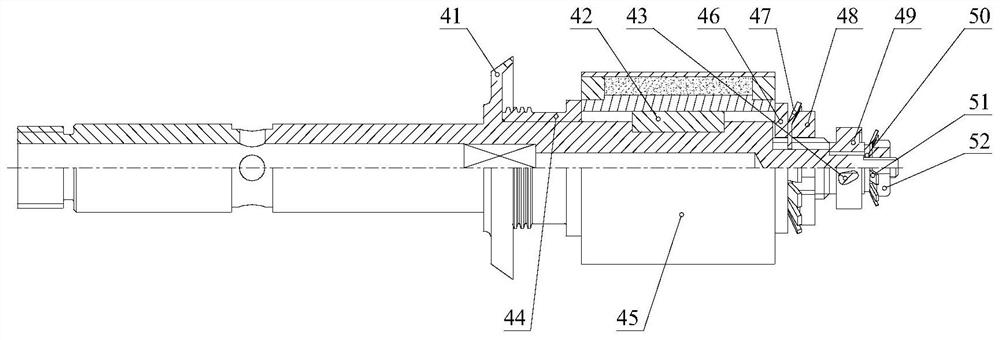

[0023] Such as Figure 1 to Figure 4 A split type high-speed generator with position feedback shown is composed of a stator 11 and a rotor 13 . The rotor 13 is a cantilever structure, the rotating shaft 41 is embedded inside the micro-gas turbine, and there is no bearing inside the motor. The bearing 3 on the generator shaft is inside the micro-gas turbine 5, and is lubricated and cooled by the lubricating oil system inside the micro-gas turbine. This design solves the cooling problem of the internal bearing of the motor at a high speed of 42000rpm; the generator is directly connected to the micro-gas turbine, and the reducer is eliminated.

[0024] The gap between the generator stator 11 and the micro-combustion engine 5 is positioned. On the generator shaft, the second bearing 8, the second sleeve 6, the first bearing 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com