Linear contact type pasture turning machine

A line contact and mower technology, applied in hay tedders, agricultural machinery and implements, applications, etc., can solve problems such as reducing forage protein content, high labor intensity, and affecting forage quality, so as to increase forage protein content , reduce the loss of forage leaves and improve the quality of forage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

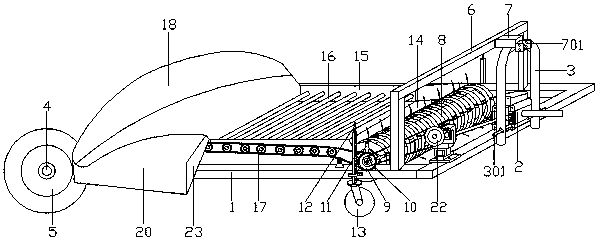

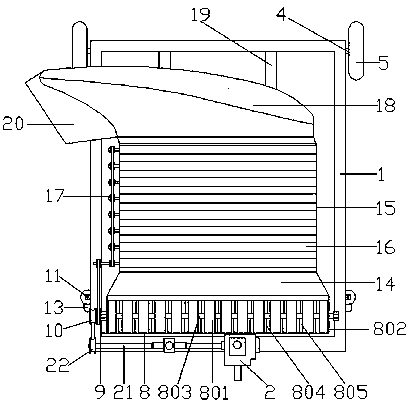

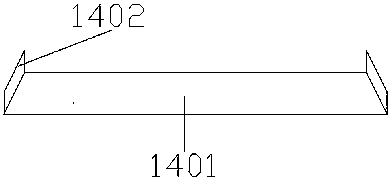

[0021] Such as figure 1 , 2 . As shown in 3, a line contact pasture mower includes a frame main body 1, the frame main body 1 is set as a rectangular frame structure, and a gear reducer 2 is installed in the center of the front beam, and the gear reducer 2 is about The corresponding positions on both sides are fixed with an arched connecting frame 3, and the relative position of the lower part of the vertical bars on both sides of the arched connecting frame 3 is a "ten" type, and a connecting pin 301 is fixed; A rotating shaft 4 is installed, and the two ends of the rotating shaft 4 are connected with walking wheels 5; the two side beams of the frame main body 1 are fixed with a door frame-like structure traction frame 6 near the corresponding position of the front end, and the traction frame 6 is connected with the arched connecting frame 3. The center of the upper part is connected with a rib plate 7, and the outer part of the rib plate 7 is provided with a bolt connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com