Fine sand filter tank and device with medium upward flow filtering speed

A technology of filtration speed and fine sand, applied in the direction of loose filter material filter, filtration separation, gravity filter, etc., can solve the problems of slow filtration speed, poor ability to adapt to raw water turbidity, long maintenance period, etc., to achieve backwashing Simple operation, ideal processing effect, easy to automate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

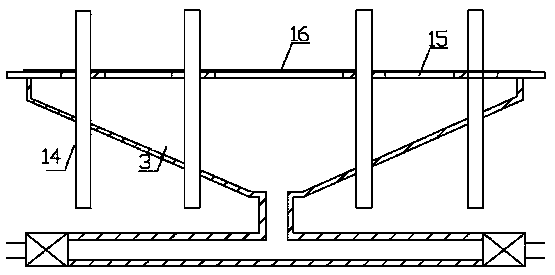

[0052] Example 1: The pool body 1 of this filter has a net size of 0.5m×0.5m×1.6m (length×width×height), and the supporting filter layer 7 is made of coarse sand with a thickness of 0.15m and a particle size of 1mm to 3mm. Fine pebbles, fine sand filter layer 8 adopts fine sand with a thickness of 0.45m and a particle size of 0.16mm to 0.36mm. The filter material unevenness coefficient K80=1.8, the filtration rate is 0.65m / h, and the total length of the long handle filter head is 0.35m , the height of entering the supporting filter layer 7 is 0.1m, the spacing is 0.1m, and the water depth of the water outlet chamber 9 is 0.4m.

[0053] The operation status of this filter: the cumulative operation time is 22 days, the maximum turbidity of the raw water is above 1000NTU, the minimum turbidity is 65NTU, the average turbidity is 432NTU, the turbidity of the effluent is 0NTU to 0.72 NTU, the supporting filter layer 7 and fine The operating water head of the sand filter layer 8 is 0...

Embodiment 2

[0054]Embodiment 2: The pool body 1 net size of this filter tank and the structure of the supporting filter layer 7 are the same as above, and the fine sand filter layer 8 adopts a thickness of 0.50m, a particle size of 0.27mm to 0.55mm fine sand, and a filter material inhomogeneity coefficient K80=1.6, the filtration rate is 2.5m / h.

[0055] The operation of the filter: the cumulative operating time is 16 days, the maximum turbidity of the raw water is above 1000NTU, the minimum turbidity is 240NTU, the average turbidity is 550NTU, the turbidity of the effluent is 10NTU to 30NTU, and the weak backwash cycle is 5h to 12h , The strong backwash cycle is 10 days, and the operating head of the filter is 0.15m to 0.40m.

[0056] Since the filtration rate of this filter is medium, the plane size of each unit filter layer should also be controlled from 0.5m×0.5m to 1.2m×1.2m. Therefore, in the specific implementation process, when the water filtration scale is large , can adopt the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com