Combined cleaning barrel and cleaning system for pharmaceutical cone-shaped bottle

A cleaning system and Erlenmeyer flask technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that the cleaning effect is difficult to meet the demand, and the outer wall of the Erlenmeyer flask cannot be effectively cleaned, etc., so as to improve the scouring , Improve the cleaning effect and the effect of cleaning a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

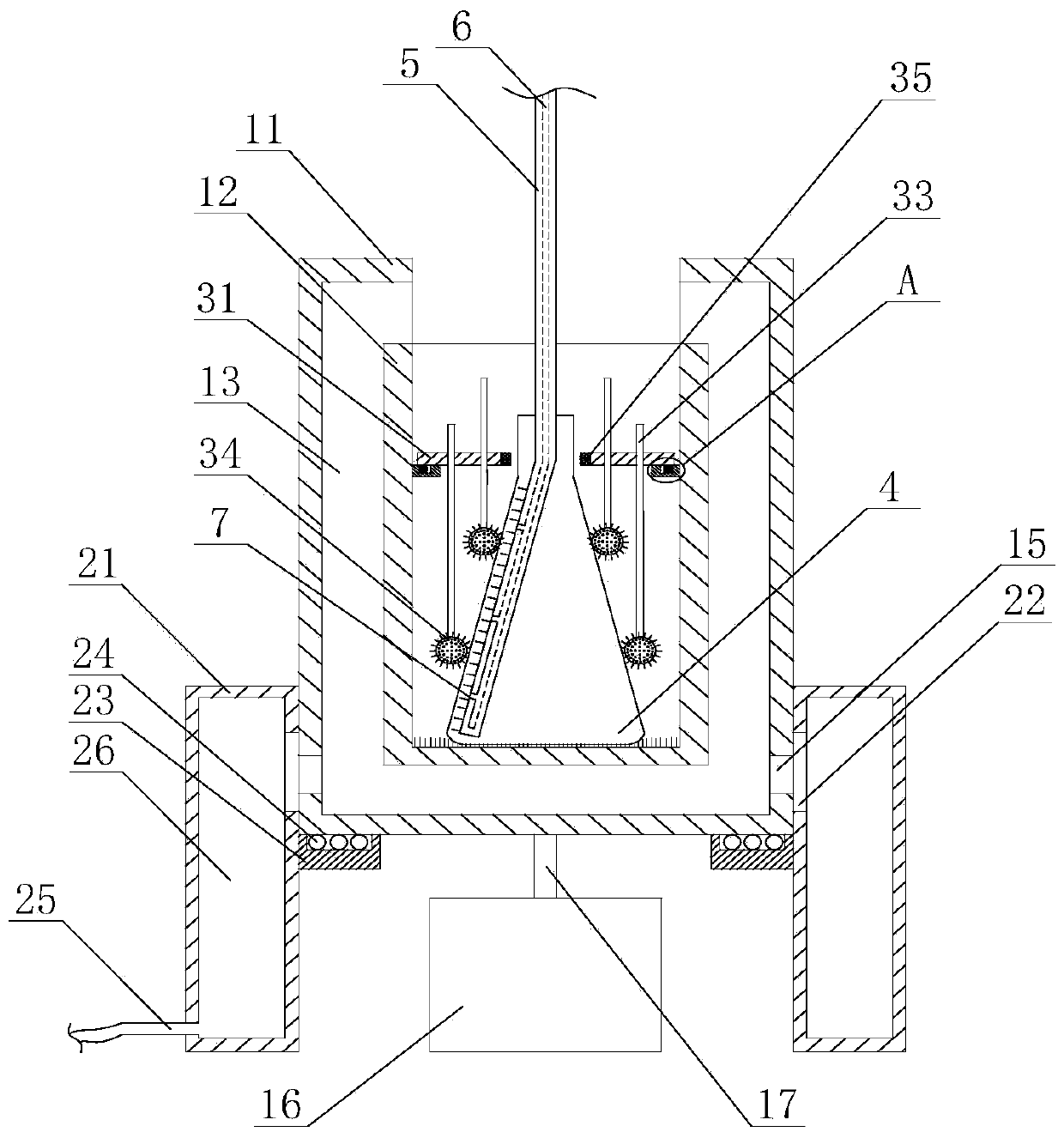

[0050] Such as Figure 1 to Figure 5 The combined cleaning cartridge for the Erlenmeyer flask for pharmaceutical use includes a first cylinder body 1 and a second cylinder body 2 sleeved outside the first cylinder body 1, and the first cylinder body 1 can be opposite to the second cylinder body 2 rotation; the first cylinder 1 is provided with a cleaning chamber, which is used for placing, cleaning and soaking the conical flask 4, and the inner wall 12 of the first cylinder 1 is provided with a first liquid inlet 14, the first cylinder A liquid outlet 15 is provided on the outer wall 11 of the body 1, and a first liquid storage chamber 13 is provided between the inner wall 12 and the outer wall 11; Two liquid storage chambers 26, the housing 21 is also provided with a second liquid inlet 22;

[0051] During the rotation of the first cylinder 1 relative to the second cylinder 2, the water flow in the cleaning chamber can pass through the first liquid inlet 14, the first liquid...

Embodiment 2

[0058] On the basis of Example 1, such as figure 2 As shown, the wall of the cleaning chamber is provided with a boss 18, and a limit mechanism 3 is installed on the boss 18, and the limit mechanism 3 is used to reduce the displacement of the Erlenmeyer bottle 4 in the longitudinal direction and / or transverse direction. move.

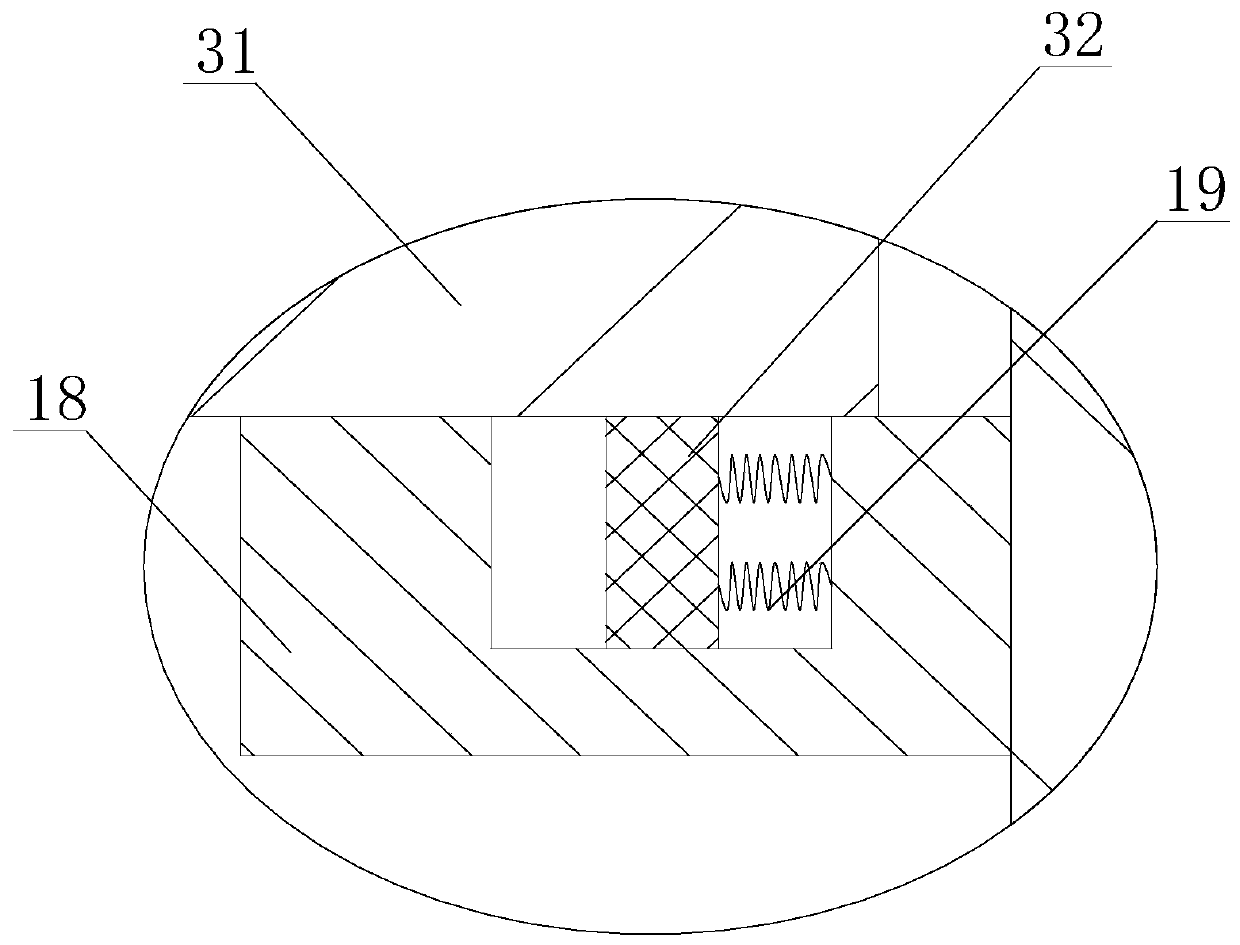

[0059] In some embodiments, such as image 3 As shown, the limiting mechanism 3 includes a limiting plate 31, and the limiting plate 31 is provided with a through hole, and the through hole is used to be sleeved on the outside of the neck of the Erlenmeyer flask 4, and the limiting plate The lower surface of 31 is provided with an arc-shaped plate 32 , and the boss 18 is provided with a mounting groove, and a spring 19 is arranged in the mounting groove, and the spring 19 is connected with the arc-shaped plate 32 .

[0060] In some embodiments, such as image 3 and Figure 6 As shown, a rubber ring 35 is arranged in the through hole of the limiting...

Embodiment 3

[0062] On the basis of the above-mentioned embodiments, the limiting plate 31 is provided with mounting holes, and the mounting holes are used to install the limiting rod 33, and the limiting rod 33 can be vertically positioned relative to the limiting plate 31. To move, the bottom end of the limiting rod 33 is provided with a positioning ball 34, the positioning ball 34 is made of rubber, preferably, the positioning ball 34 is made of fluorine rubber.

[0063] In some embodiments, such as Figure 6 As shown, along the radial direction of the limiting plate 31 , two sets of mounting rods 33 are provided, and each group of mounting rods 33 is evenly distributed along the circumferential direction of the limiting plate 31 . Preferably, the number of a group of installation rods 33 close to the center of the limiting plate 31 is four, and the number of a group of installation rods 33 away from the center of the limiting plate 31 is eight.

[0064] In some embodiments, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com