Tool adjusting mechanism for plate shearing machine

A technology of adjusting mechanism and shearing machine, which is applied to the accessories of shearing machine, shearing machine equipment, shearing device, etc. The effect of flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

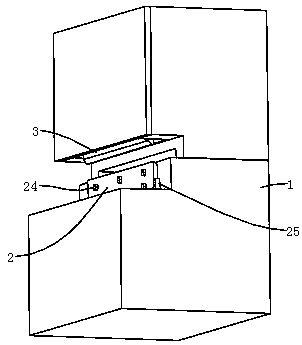

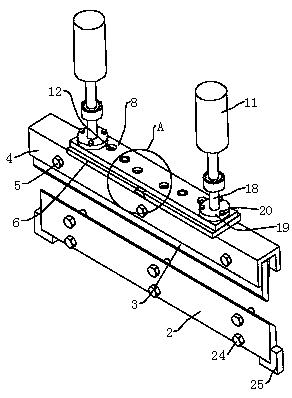

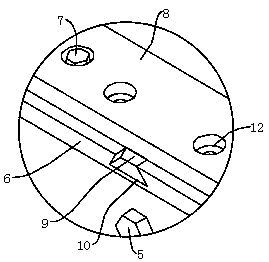

[0027] refer to figure 1 , figure 2 and image 3 , the knife adjustment mechanism for the shearing machine, including the lower blade 2 installed and fixed in the shearing machine body 1 and the upper blade 3 for matching and cutting with the lower blade 2; The blade 3 can be pressed down and the gap can be adjusted, and the top of the upper blade 3 is snapped into the opening of the U-shaped clamping plate 4, wherein the U-shaped clamping plate 4 and the upper blade 3 are connected by four first locking bolts 5 , a first connecting plate 6 is welded and fixed on the top of the 匚-shaped clamping plate 4, and a second connecting plate 8 is installed and fixed horizontally above the first connecting plate 6 through two second locking bolts 7 in an adjustable manner. The cylinder body of two hydraulic cylinders 11 is symmetrically fixed in the machine body 1, and the ends of the piston rods of the two hydraulic cylinders 11 are respectively connected and fixed above the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com