Buffering and dust removing device for coal falling point of underground coal mine belt conveyor

A technology of conveyor belt and dust removal device, applied in the directions of transportation and packaging, conveyor objects, loading/unloading, etc., can solve the problems of lower conveyor belt damage, coal dust pollution, etc., to reduce impact damage, prolong service life, reduce Effects of coal dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

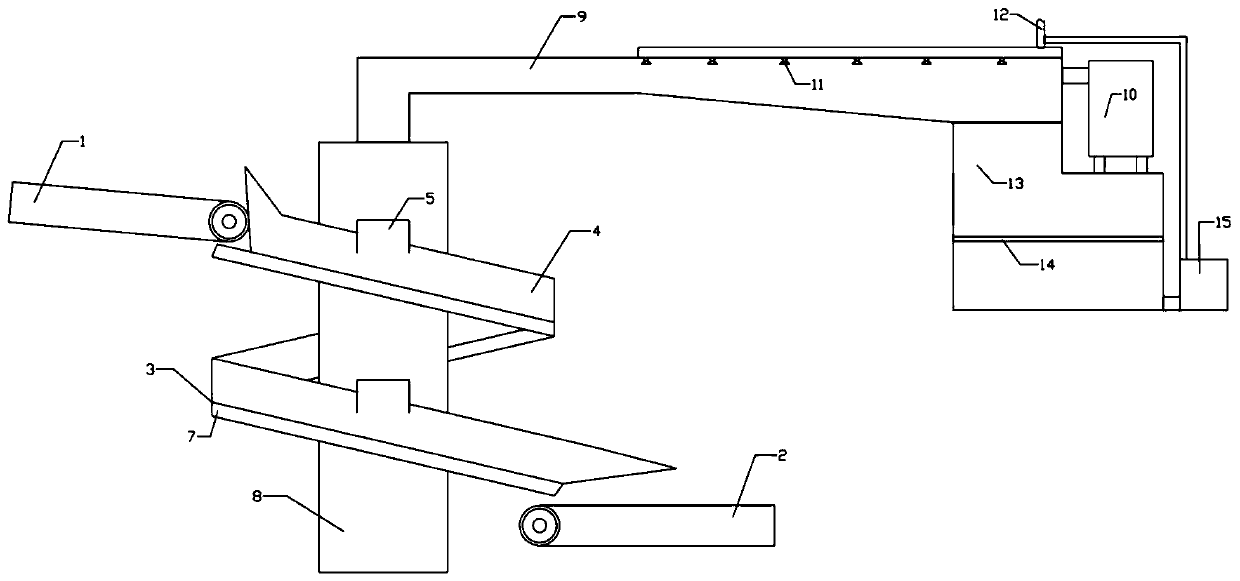

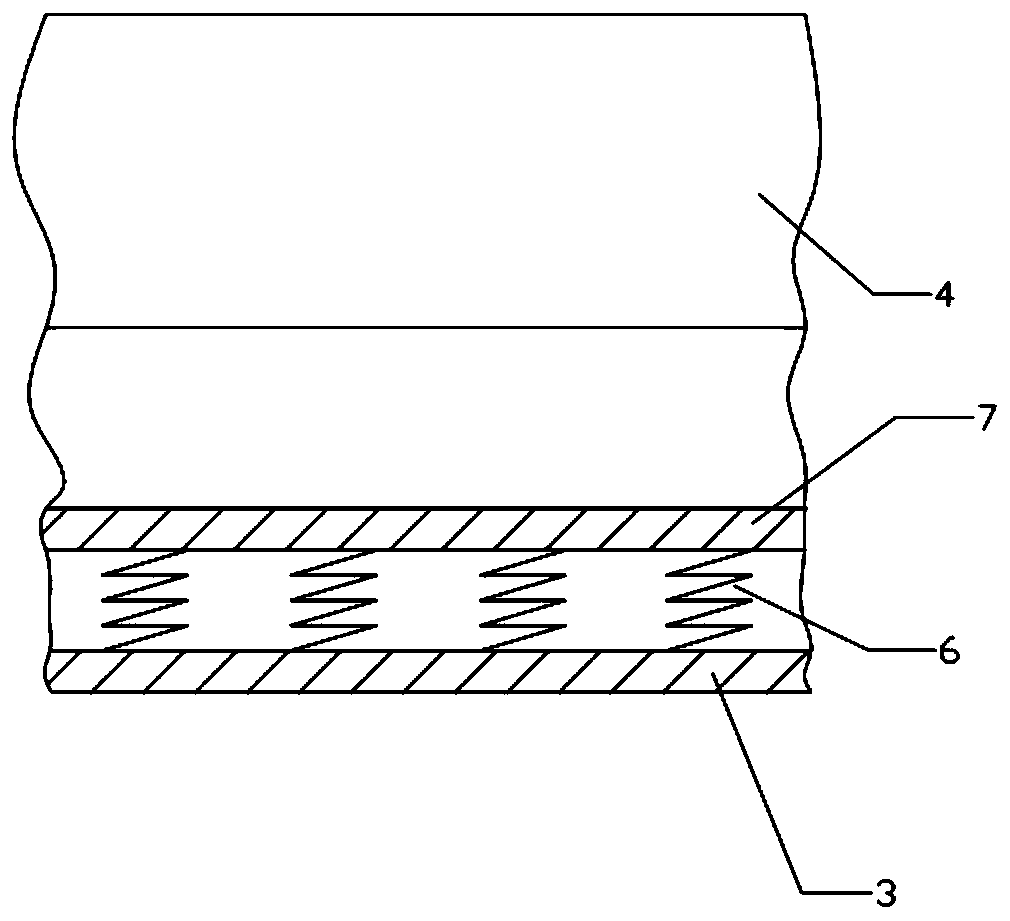

[0023] An underground coal mine transport belt conveyor coal drop point buffer dust removal device, such as figure 1 , figure 2 As shown, it includes a buffer slide 3, a dust collection channel 4, a shock absorbing slide 7, a support column 8, and a dust removal mechanism.

[0024] A buffer slide 3 is arranged between the upper conveying belt 1 and the lower conveying belt 2, and the buffer slide 3 is arranged obliquely, and the inclination of the upper half of the buffer slide 3 is greater than that of the lower half. The upper end of the buffer slide 3 is positioned below the discharge end of the upper conveyor belt 1, and the lower end of the buffer slide 3 is positioned above the feed end of the lower conveyor belt 2.

[0025] When the coal falls from the upper conveyor belt 1 to the buffer slide 3, the buffer slide 3 buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com