Movable yarn pre-cleaning power providing device and method

A technology of power and yarn board, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of increased workload of winder maintenance, inability to fall off automatically, and increased manufacturing costs, and reduce the later stage. Maintenance workload, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

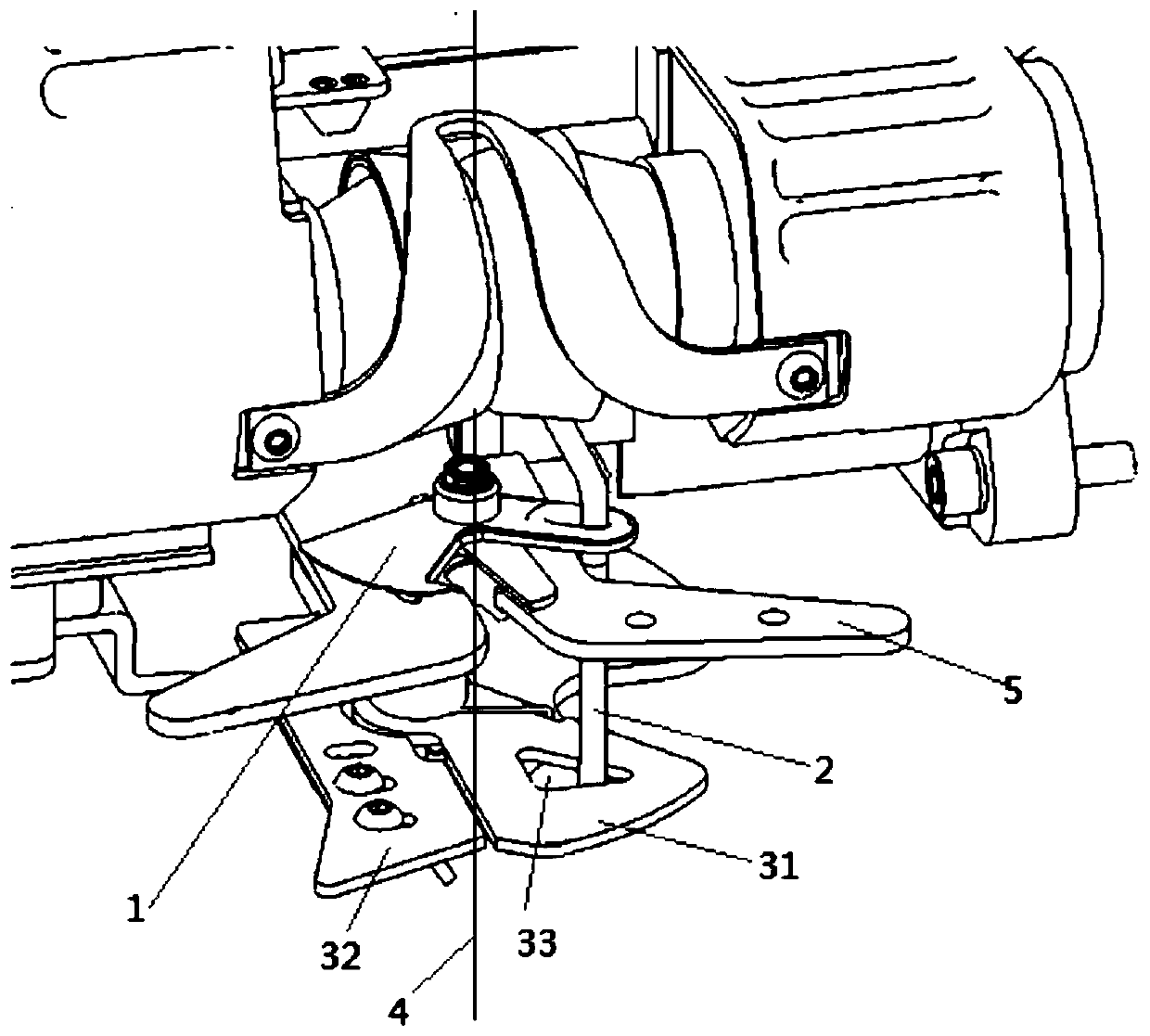

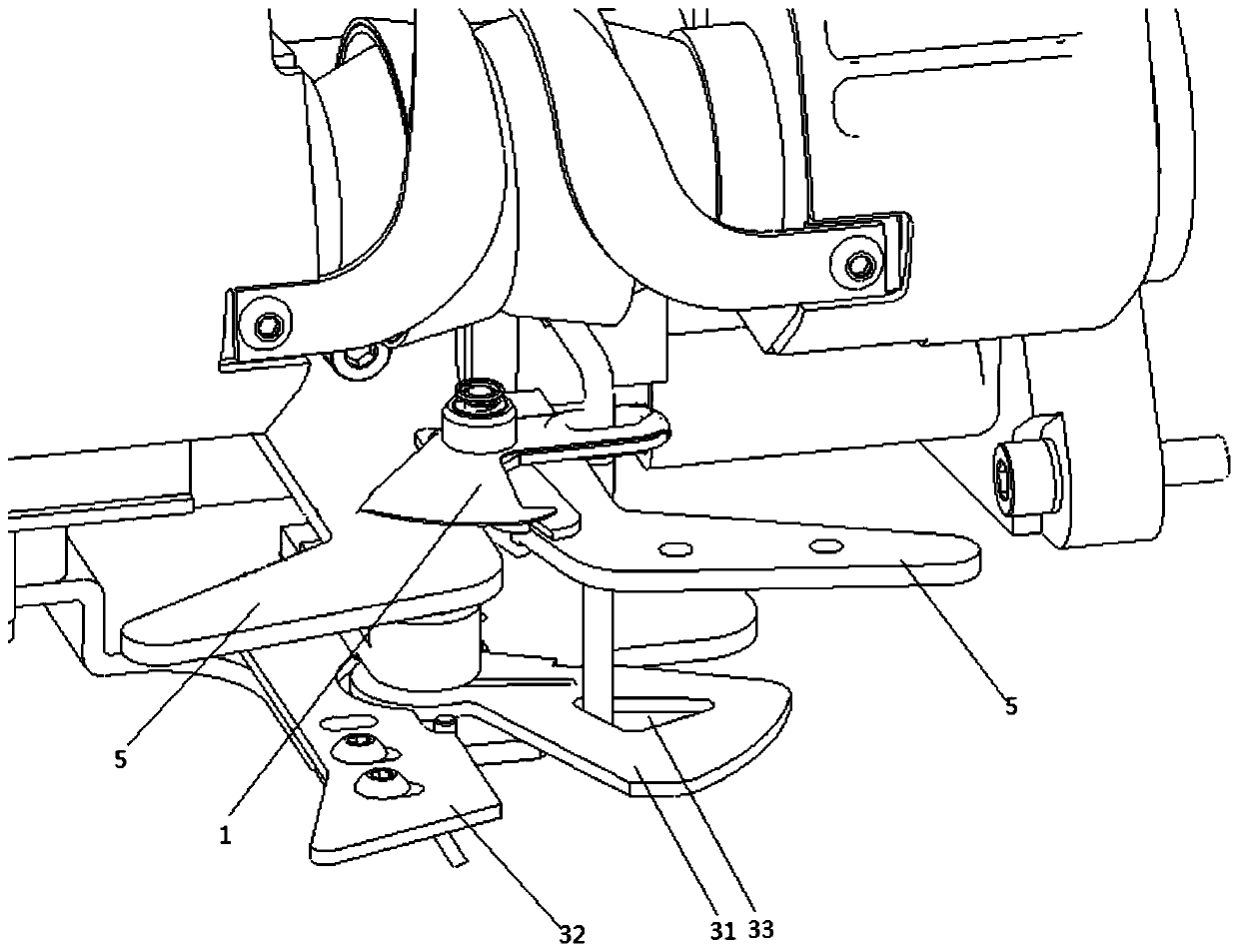

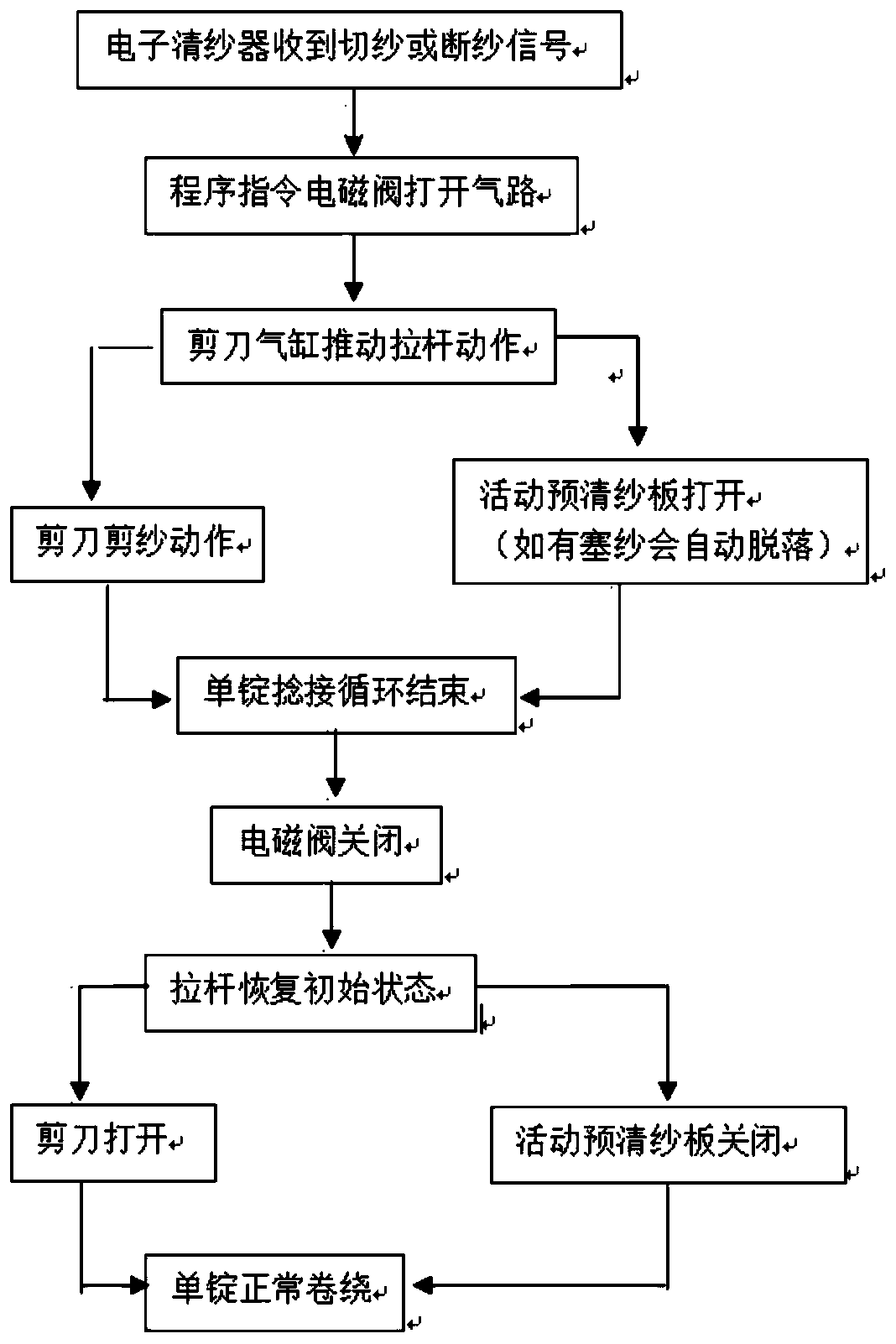

[0017] Such as figure 1 , 2 As shown, a movable pre-clearing power supply device includes scissors 1, an air cylinder that drives the scissors 1 to perform a yarn reduction action, and a scissors pull rod 2 connecting the air cylinder and the scissors; a movable pre-clearing assembly 3 is provided directly below the scissors The movable pre-clearing assembly includes a movable pre-clearing board 31 and a fixed pre-clearing board 32. The movable pre-clearing board is provided with a hole 33, and the scissors rod extends downward to pass through the movable pre-clearing board. The hole 33 on the plate; the opening and closing state of the scissors is opposite to the opening and closing state of the pre-clearing plate. A yarn guide plate 5 is provided under the scissors. The scissors are divided into movable scissors and fixed scissors. The movable scissors and the movable pre-clearing plate are connected by a scissors pull rod; the fixed scissors are fixed on the yarn guide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com