Laminated regulation and control vacuum tempered glass plate with double-rubber sealing groove edge supporting and buckling

The technology of glass plate and sealing groove is applied in the field of adjusting the vacuum insulation function of tempered glass plate, which can solve the problems of high yield and low cost, and achieve the effects of high yield, low cost and good perspective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

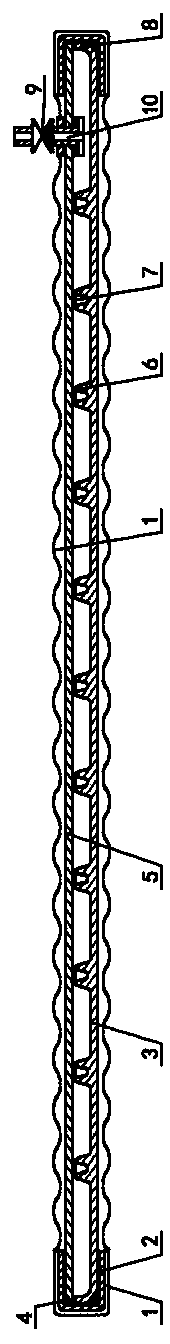

[0199] Such as figure 1 As shown: the parallel bending support frame 8 of the upper tempered glass 5 and the parallel bending support frame 6 of the lower tempered glass 3 distributed with dot matrix embossed support bumps 6 correspond to each other in outline shape and size, Complementary fastening, spaced to form a vacuum interlayer. The closed-loop "U"-shaped stainless steel corrugated protective frame 1 is bonded with the structural sealant 2 and the airtight sealant 4 to form a vacuum toughened glass plate supported by the frame of the tempered glass plate and bonded to each other with the stainless steel frame. An intake and exhaust pipe 10 is installed on the vacuum tempered glass plate, and an exhaust vacuum valve 9 is arranged on the intake and exhaust pipe 10 .

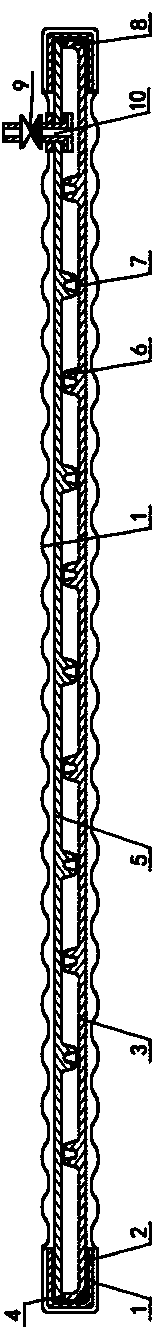

[0200] Such as figure 2 As shown: the upper tempered glass 5 and the lower tempered glass 3 are distributed with dot matrix embossed support bumps 6, and the others are equivalent to figure 1 .

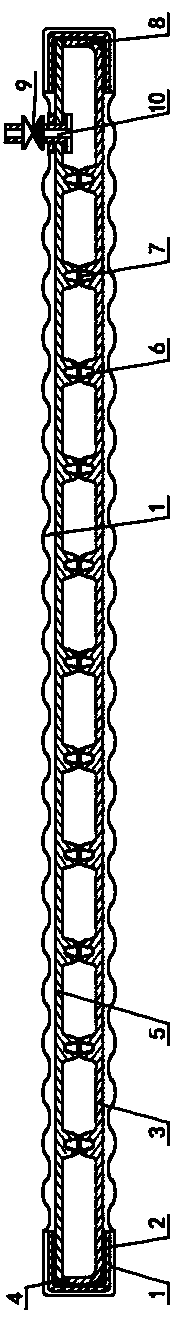

[0201] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com