A kind of preparation method of large-diameter high-strength medium-modulus carbon fiber and high-strength high-modulus carbon fiber

A large-diameter, carbon fiber technology, applied in the field of large-diameter carbon fiber preparation, can solve the problems of prolonged pre-oxidation time, insufficient pre-oxidation of the core, and difficulty in jumping out of the thinking mode, and achieve simple process operation methods and radial structure differences. Small, improves collimation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of spinning dope

[0040] Using azobisisobutyronitrile as the initiator and dimethyl sulfoxide as the solvent, mix acrylonitrile, itaconic acid and methyl acrylate at a molar ratio of 98.5:0.5:1 and add them to the polymerization reaction vessel. The polymerization reaction temperature is 62°C , the polymerization reaction time is 23 hours, the stirring rate is 50rpm, and the spinning stock solution is obtained, and the spinning stock solution is obtained after the single and defoaming, and the acrylonitrile copolymer with a polymer molecular weight of 185,000 is obtained. The sulfone accounts for 78% of the mass percent concentration of acrylonitrile and dimethyl sulfoxide, the azobisisobutyronitrile accounts for 0.15% of the acrylonitrile mole fraction, and the viscosity of the spinning dope measured by a rotational viscometer at 25° C. is 8600 poise.

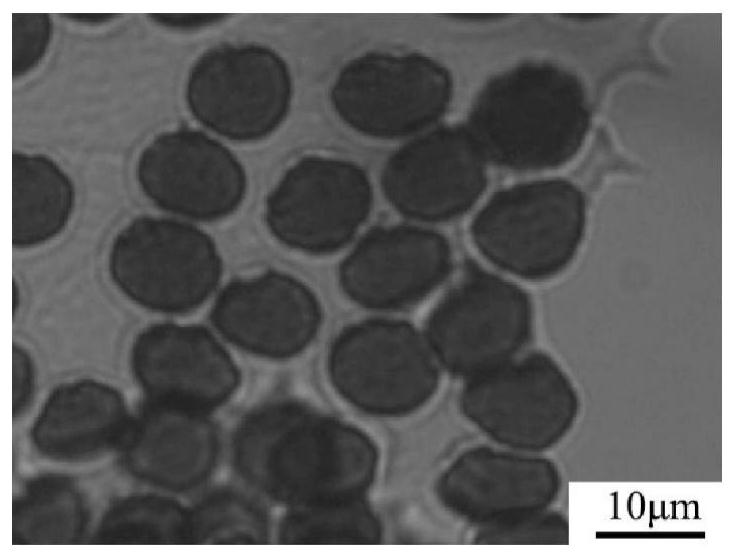

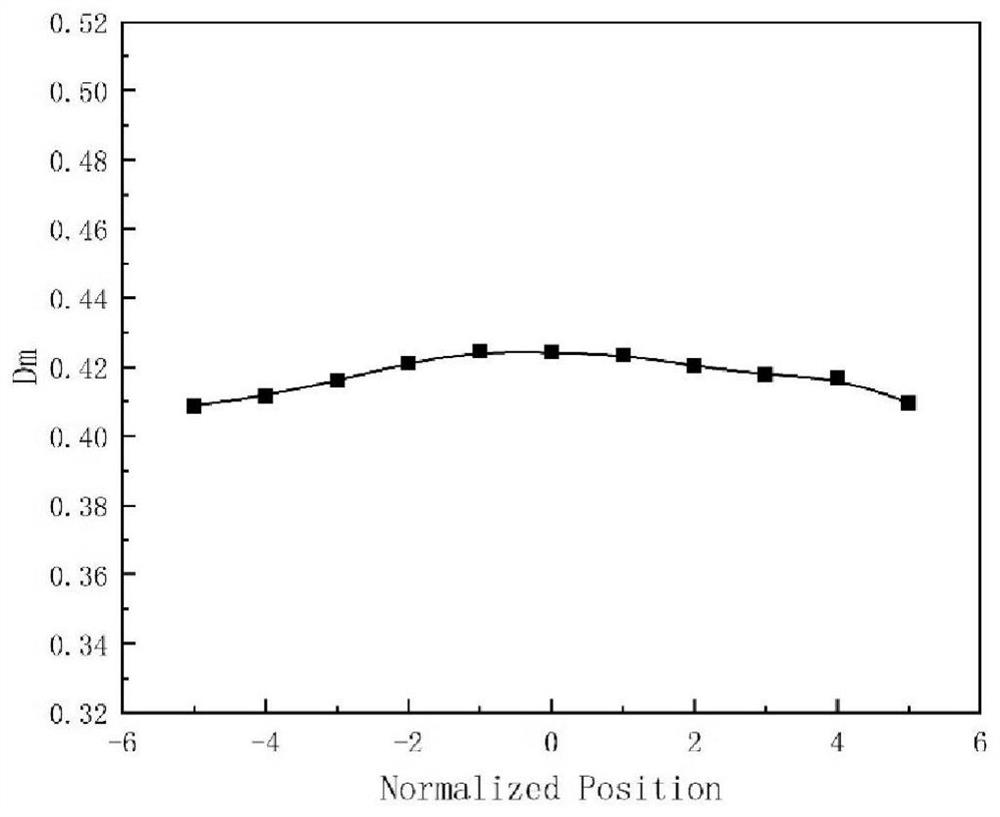

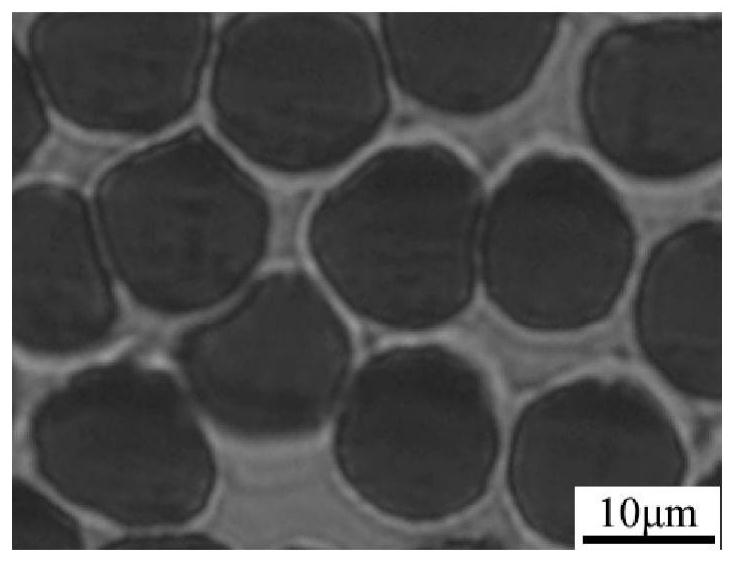

[0041] (2) Multi-stage coagulation molding of spinning dope

[0042] Adopt the spinneret that hole ...

Embodiment 2

[0061] (1) Preparation of spinning dope

[0062] Using azobisisobutyronitrile as the initiator and dimethyl sulfoxide as the solvent, mix acrylonitrile, itaconic acid and methyl acrylate at a molar ratio of 98.5:0.5:1 and add them to the polymerization reaction vessel. The polymerization reaction temperature is 60°C , the polymerization reaction time is 23 hours, the stirring rate is 55rpm, and the spinning stock solution is obtained, and the spinning stock solution is obtained after the single and defoaming, and the acrylonitrile copolymer with a polymer molecular weight of 175,000 is obtained. The sulfone accounts for 79% of the mass percent concentration of acrylonitrile and dimethyl sulfoxide, the azobisisobutyronitrile accounts for 0.20% of the acrylonitrile mole fraction, and the viscosity of the spinning dope measured by a rotational viscometer at 25° C. is 7500 poise.

[0063] (2) Multi-stage solidification of spinning dope

[0064] Adopt the spinneret that hole diame...

Embodiment 3

[0073] (1) The preparation of spinning dope is the same as in Example 1

[0074] (2) Multi-stage solidification of spinning dope.

[0075] Adopting the spinneret whose aperture is 0.10mm, the linear velocity of the fiber at the spinneret is 5.78m / min, and the fiber passes through the air layer of 10mm after leaving the spinneret, and then enters the first coagulation bath, and the temperature of the first coagulation bath is 30 ℃, the coagulation bath adopts dimethyl sulfoxide aqueous solution, wherein the volume content of dimethyl sulfoxide solvent is 76%, the coagulation time is 2.5 minutes, and the coagulation draft ratio is 3; the speed of coagulation filaments exiting the first coagulation bath is 17.34m / min, then the fiber enters the second coagulation bath, the temperature of the second coagulation bath is 30°C, the coagulation bath adopts the aqueous solution of dimethyl sulfoxide, wherein the volume content of dimethyl sulfoxide solvent is 50%, the coagulation time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com