A kind of prefabricated and assembled steel truss web concrete composite bridge and construction method

A prefabricated assembly and construction method technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as low construction accuracy, poor bridge integrity, and long construction period, so as to improve construction accuracy and quality, and increase the abdominal area. Pole area, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

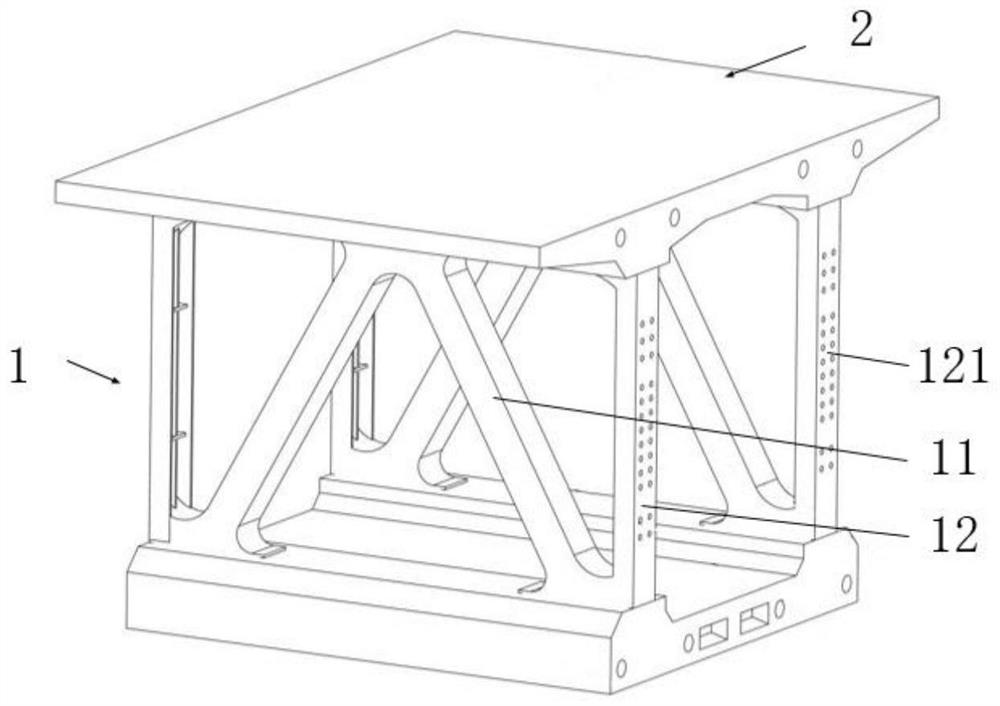

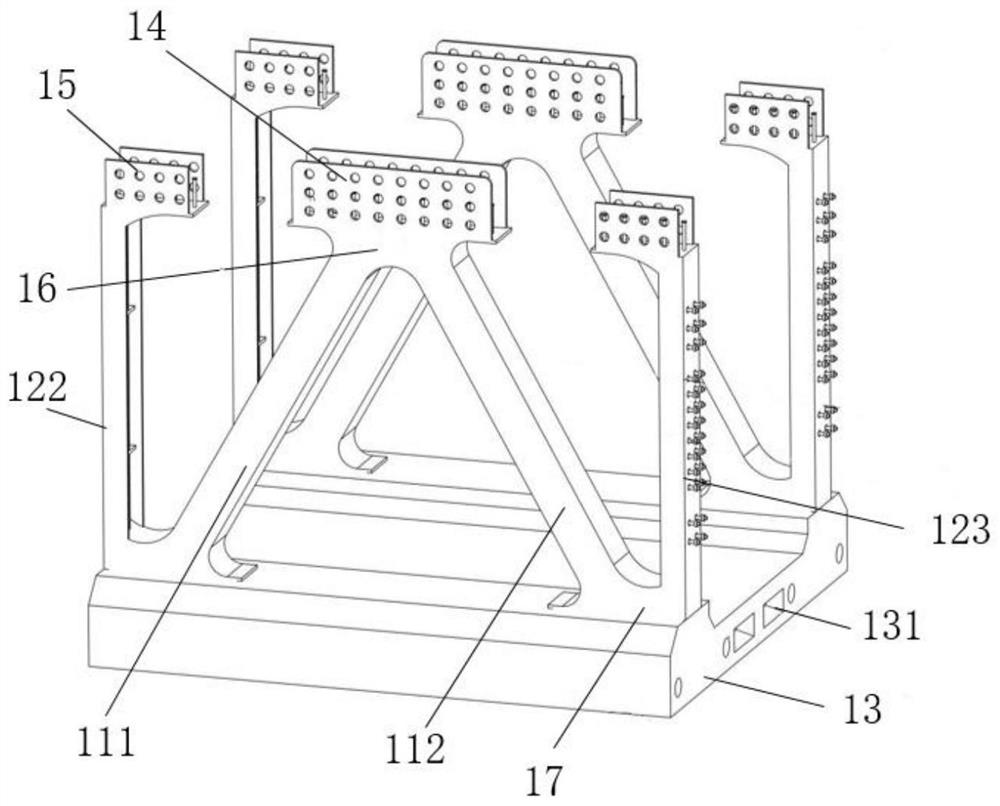

[0041] A specific embodiment of the present invention, such as Figure 1-Figure 2 As shown, a prefabricated and assembled steel truss web concrete composite bridge is disclosed, which includes a plurality of segment units, the segment units are steel truss web concrete composite bridge segment units, and the segment units include prefabricated open channel beams 1 and cast-in-place beams. The top plate 2, the cast-in-place top plate 2 is set on the top of the prefabricated open channel beam 1; One end of 11 is connected with the bottom plate 13, the other end is connected with the connecting piece 14, one end of the steel vertical rod 12 is connected with the steel girder web 11, and the other end is connected with the semi-connecting piece 15, both of which are connected with the cast-in-place top plate 2 connect.

[0042] The steel truss web 11 is a steel tube member, and the use of the steel tube member reduces the overall weight of the prefabricated open channel beam 1 . ...

Embodiment 2

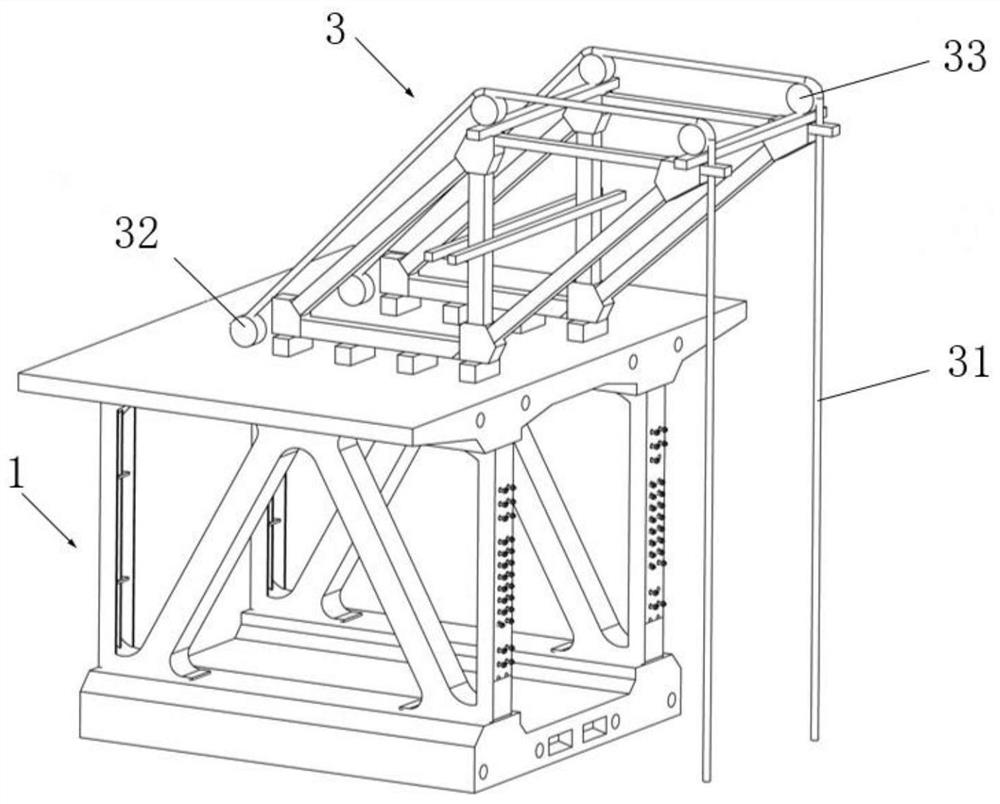

[0050] A specific embodiment of the present invention, such as Figure 3-Figure 6 As shown, a construction method of a prefabricated and assembled steel truss web concrete composite bridge is disclosed. The construction method is used to construct the prefabricated and assembled steel truss web concrete composite bridge of the first embodiment. The steps include:

[0051] Step 1: Prepare the prefabricated open channel beam;

[0052] The prefabricated open channel beam 1 is prefabricated, and the prefabricated open channel beam 1 of the nth segment unit is transported to the construction position, n≥2.

[0053] The prefabricated open channel beam 1 is completed in the factory and then transported to the construction site, which can not only ensure the precise positioning of the steel truss web 11, but also improve the quality of the concrete of the bottom plate 13. The steel truss web 11, the steel vertical rods 12 and the bottom plate 13 are prefabricated in the factory and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com