Hydraulic retractable fishing spear for horizontal well

A technology for horizontal wells and fishing spears, which is applied in wellbore/well parts, earthwork drilling and production, etc., which can solve problems such as low fishing success rate, complicated downhole accidents, and increased frictional resistance, so as to improve the fishing success rate and overcome the problems of wellbore Structural constraints, structurally sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

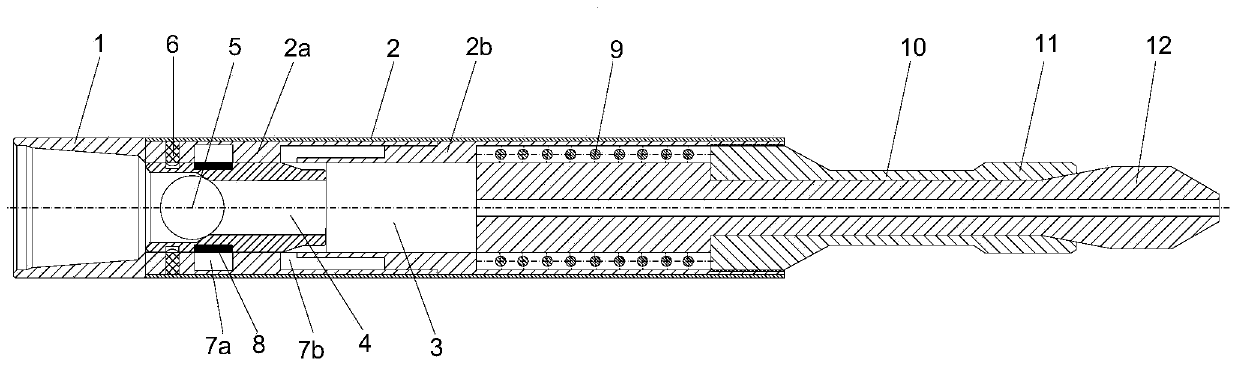

[0022] figure 1 The structural sectional view of the horizontal well hydraulic retractable fishing spear provided by the embodiment of the present invention; figure 1 As shown, a horizontal well hydraulic retractable fishing spear provided in this embodiment includes an upper joint 1, a sleeve 2, a central pipe 3, an upper piston cylinder 2a, a lower piston cylinder 2b, a fishing claw 10 and a spear shaft 12; One end of the sleeve 2 is fixedly connected to the outer wall of one end of the upper joint 1, one end of the central tube 3 is fixedly connected to the inner wall of one end of the upper joint 1, and the upper piston cylinder 2a and the lower piston cylinder 2b are sleeved on the sleeve 2 and the central tube 3, and one end of the upper piston cylinder 2a is sleeved and fixedly connected with one end of the lower piston cylinder 2b, and forms a lower liquid inlet groove 7b from the inner wall of the lower piston cylinder 2b to its interior direction, and the lower inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com