Intelligent calibration device and method for steady-state fluid force of valve element of proportional valve

A proportional valve and hydraulic power technology, applied in the field of proportional valves, can solve the problems of changing the structure of the valve body, unable to disassemble the structure of the proportional valve, etc., and achieve the effect of effective measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

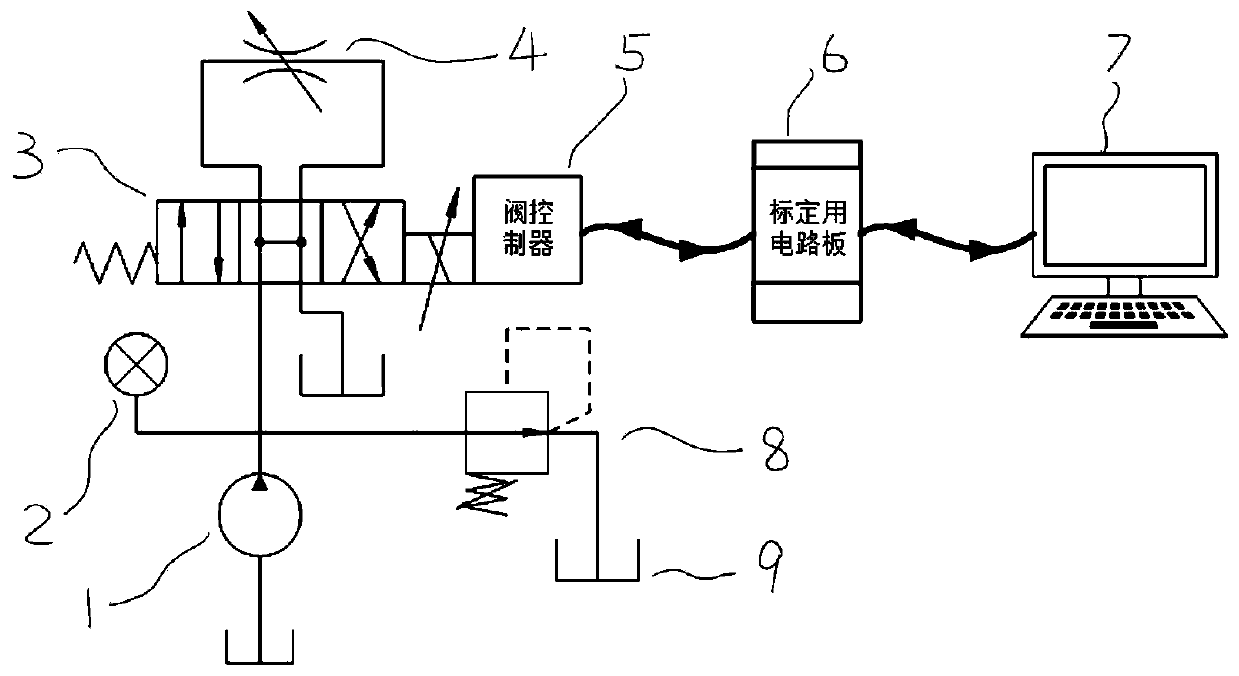

[0025] Please see the attached picture, in the figure 1 is the hydraulic pump, 2 is the pressure sensor, 3 is the proportional valve, 4 is the throttle valve, 5 is the valve controller, 6 is the circuit board for calibration, 7 is the PC, 8 is the relief valve , 9 is the fuel tank.

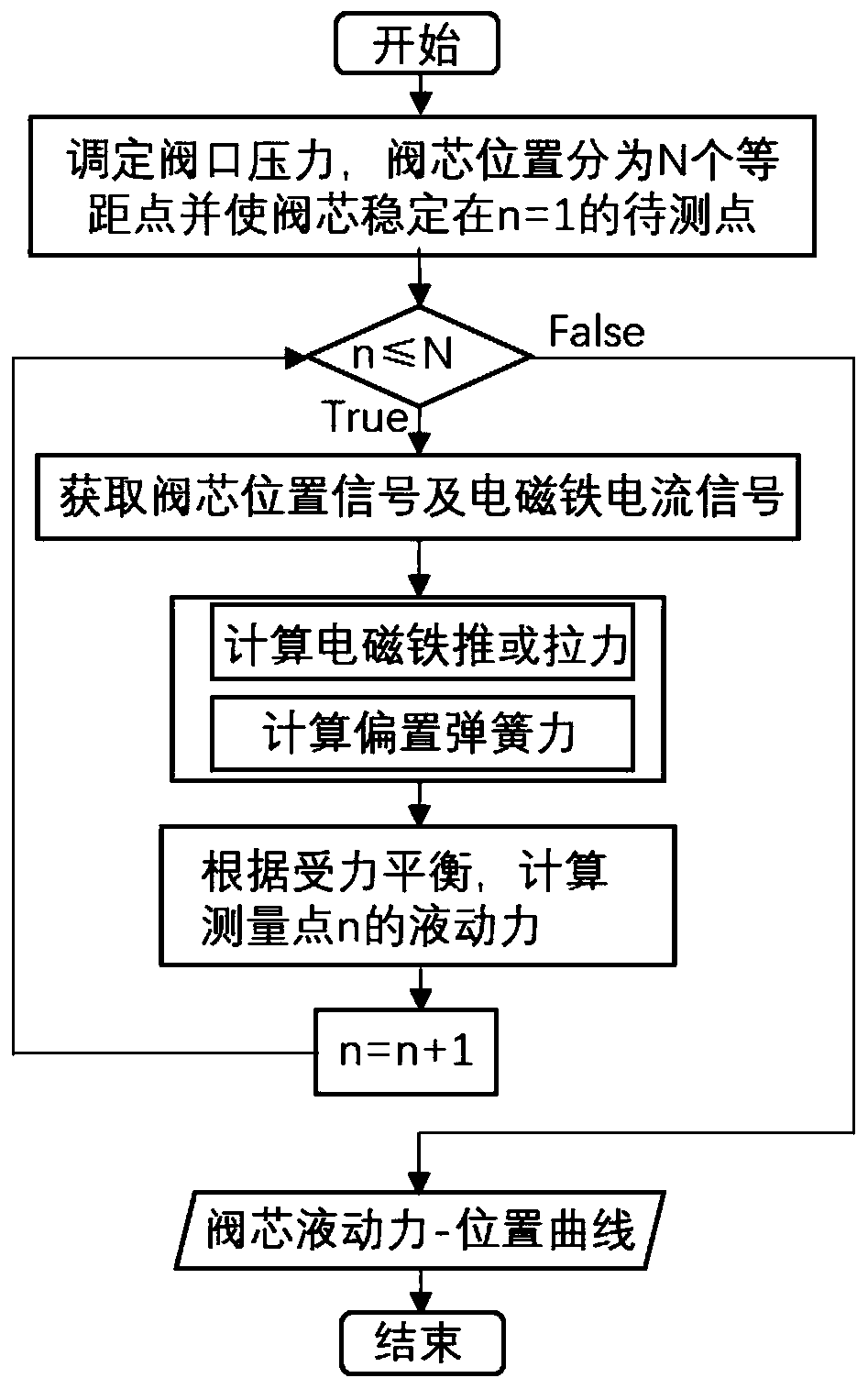

[0026] Such as figure 1 As shown, the present invention mainly relies on a single-chip microcomputer system with signal acquisition and communication functions such as figure 1 , calculate and process the collected signals in the single-chip microcomputer to obtain the hydrodynamic calibration results and output them to the computer. The processing flow is as follows figure 2 shown.

[0027] See figure 1 , the intelligent calibration device of the proportional valve spool steady-state hydraulic power of the present invention, the proportional valve includes a proportional valve 3 valve body and a valve controller 5, which includes a hydraulic pump 1 that pumps oil from the oil tank 9 to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com