Novel dual-drive fully-closed coal gas water seal gate valve

A dual-drive, fully enclosed technology, used in sliding valves, valve details, valve devices, etc., can solve the problems of large occupied space, single installation method, sealing leakage, etc., to overcome internal and external leakage of the valve, flexible and reliable transmission, and installation space. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

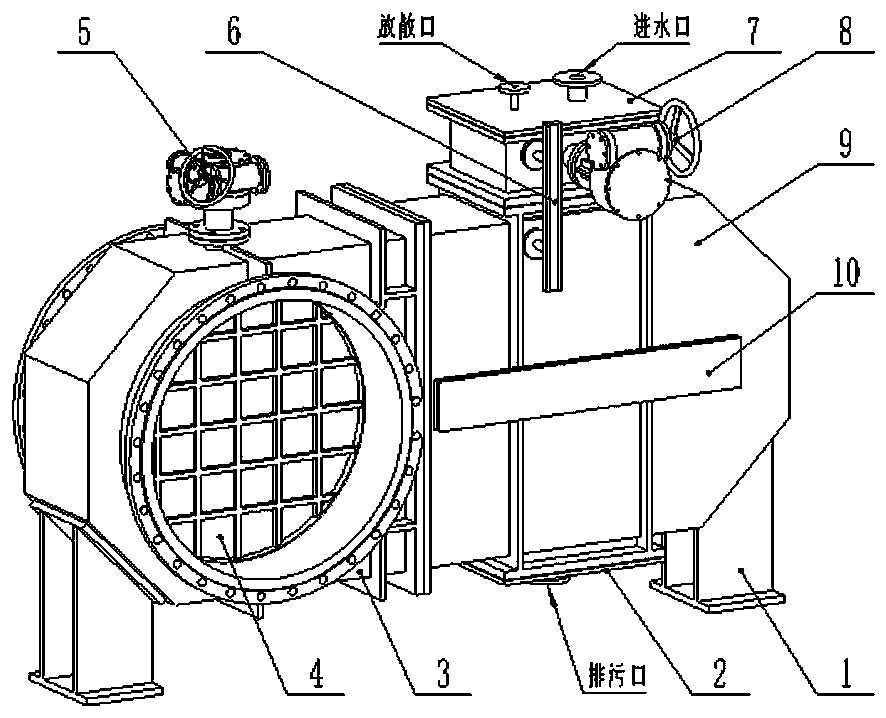

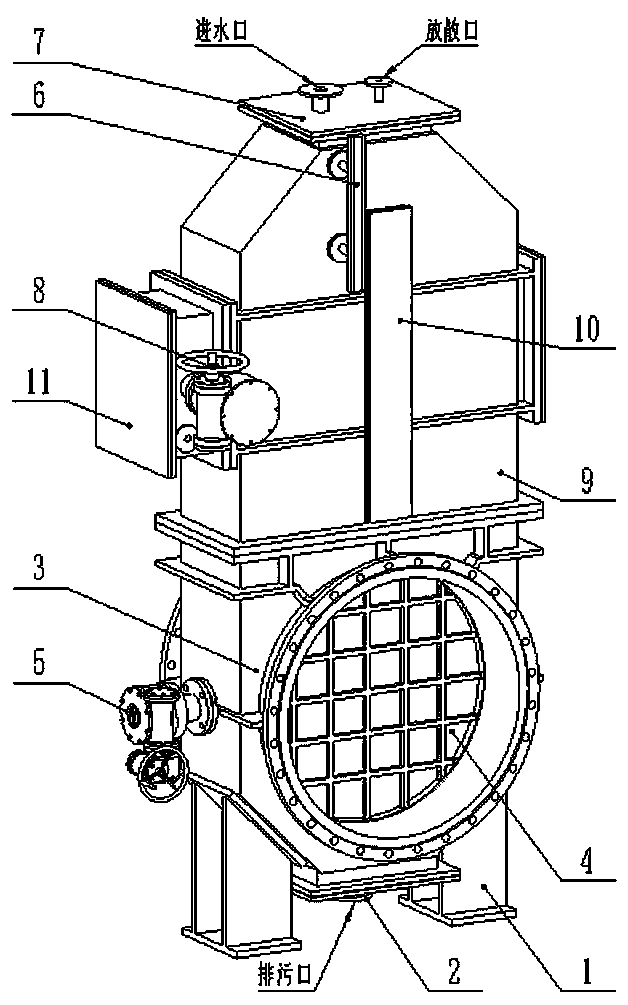

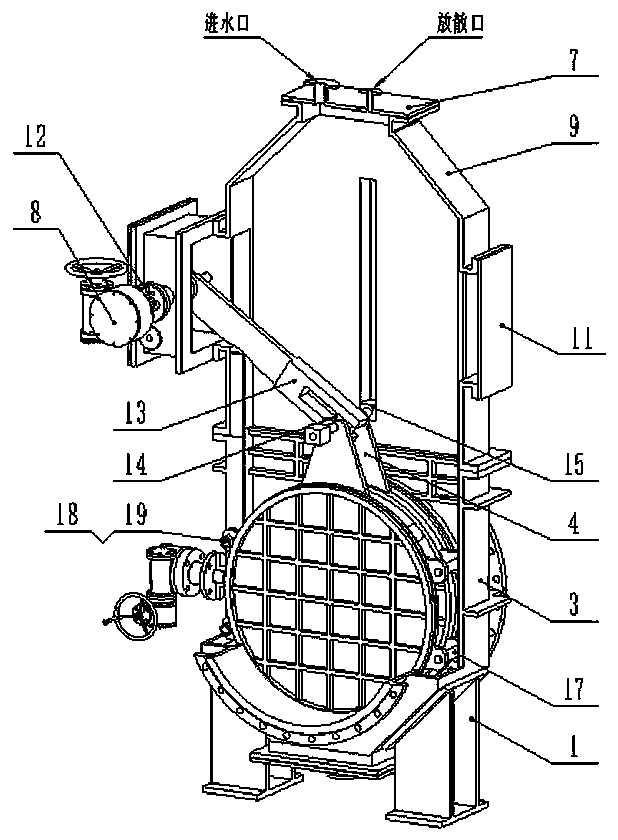

[0056] as attached figure 1 , 2 The new double-drive fully-enclosed gas water-sealed plug-in valve is composed of a foot 1, a bottom cover 2, a valve body 3, a valve plate 4, a water level gauge or a pressure gauge 6, a top cover 7, a valve cover 9, an observation cover 10, Side cover 11, roller shaft 17, roller 18, roller shaft 19, spring 20, valve opening and closing mechanism (attached image 3 ), valve plate tightening mechanism (attached Figure 4 , 5 , 6) Composition.

[0057] The top cover 7 is installed on the valve cover 9, and the top cover 7 is provided with a water inlet and a discharge port. The water inlet is used to inject water into the valve cavity after the mechanical hard seal has been formed between the valve plate 4 and the valve body 3 to form a water seal to isolate the valve. Medium at both ends, and the vent is used to discharge the air in the body cavity when injecting water.

[0058] The valve body 3 (for vertical installation) or valve cover 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com