Assembly type fire pump room hoisting construction method and structure based on BIM technology

A construction method and prefabricated technology, applied in the direction of pipeline support, pipe/pipe joint/pipe fitting, geometric CAD, etc., can solve the problems of difficult construction, long construction period, backward technology, etc., to shorten the construction period, improve construction efficiency, The effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

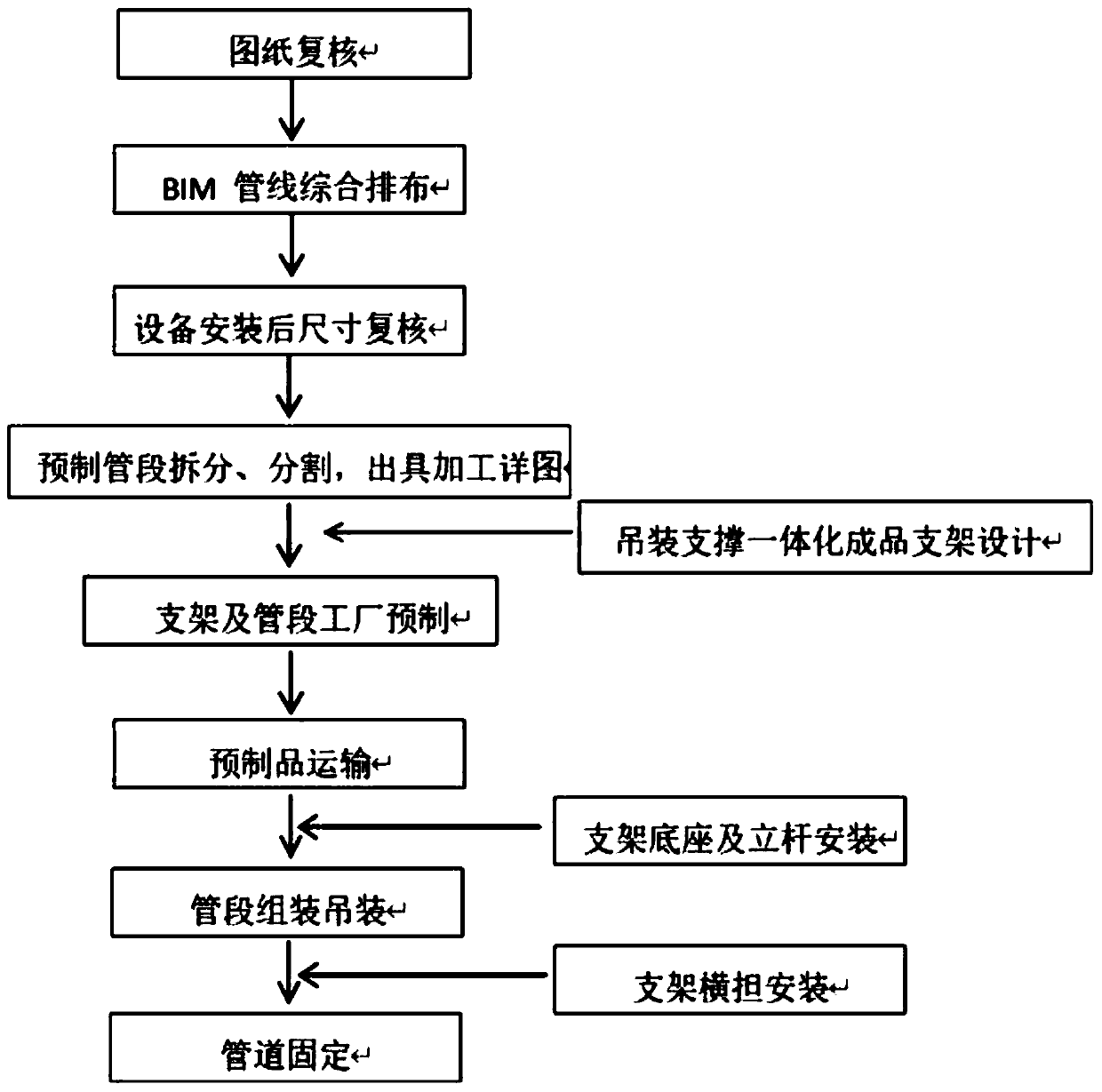

[0050] A hoisting construction method for a prefabricated fire pump room based on BIM technology, which uses BIM technology to comprehensively arrange and accurately model the equipment and pipelines in the machine room, determine the installation location and elevation of the equipment and pipelines, and divide the prefabricated processing sections of the pipelines;

[0051] Set the form and installation position of the support and hanger, and design an integrated hoisting support system;

[0052] Professional factories prefabricate and process pipe sections and supports and hangers according to BIM processing drawings, and mark them with QR codes. ;

[0053] After the pipe sections and supports and hangers are processed, they are transported to the site of the machine room, and the on-site construction personnel complete the assembly of the pipe modules at one time according to the hoisting sequence determined by the construction plan according to the BIM processing drawing ...

Embodiment 2

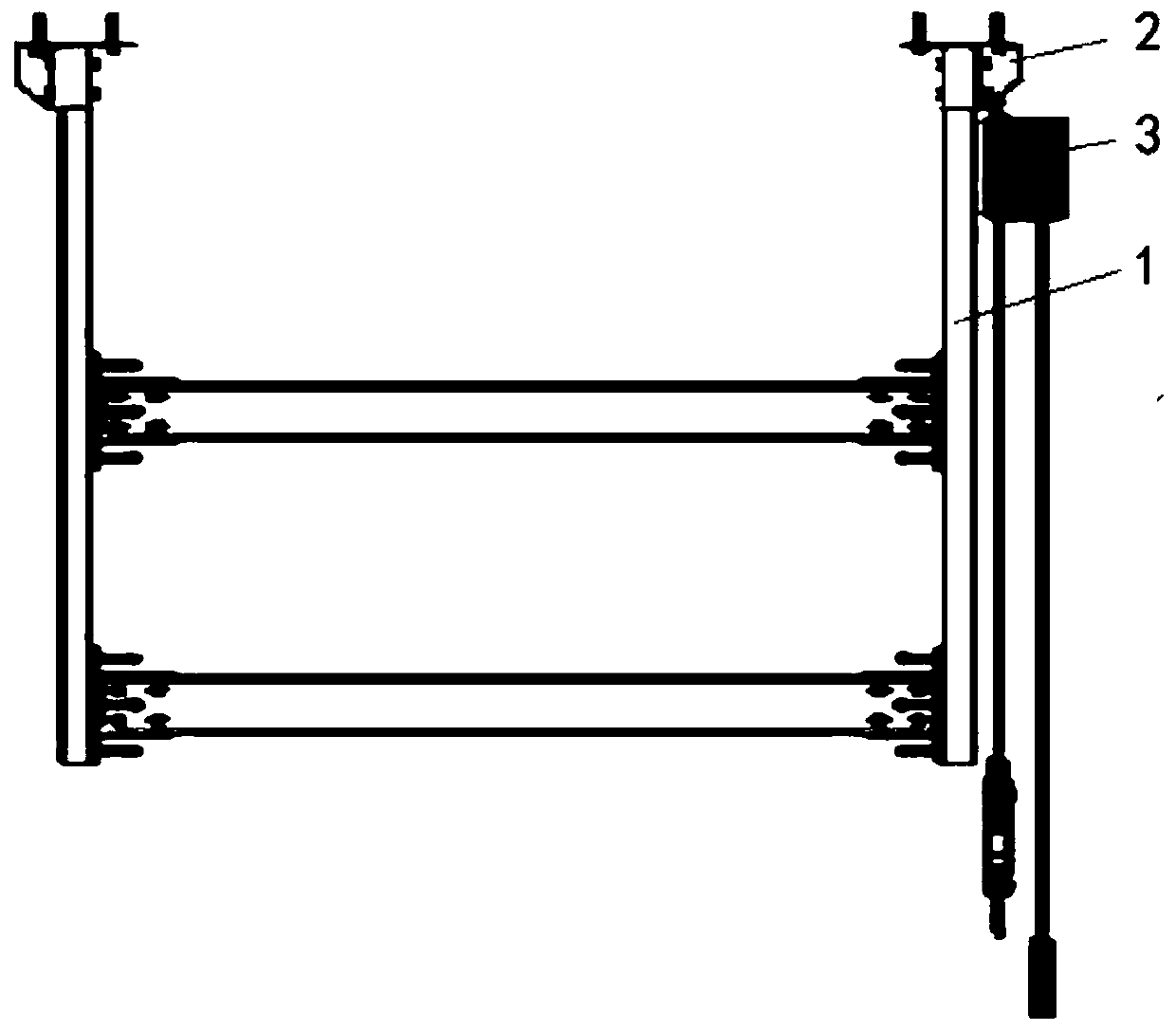

[0102]A hoisting construction structure of a prefabricated fire pump room based on BIM technology, which is characterized in that the prefabricated pipe section is split and divided through BIM technology modeling, and the integrated bracket is hoisted and supported according to the hoisting sequence determined by the construction plan. The pipeline modules are assembled and hoisted;

[0103] The hoisting and supporting integrated bracket includes a support frame and a hoist 3, the support frame includes a support part 1 and a fixed part 2, the support part 1 is used for pipeline support, and the hoist 3 is fixed on the support frame; the fixed part 2 is provided with a connection fixing hole , used to connect fixed hoisting pipes and brackets.

[0104] When installing the pipeline, fix the pipeline or bracket and other accessories to be installed on the fixed part 2 of the hoisting support integrated bracket, support and fix the pipeline or bracket through the support part 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com