Rotary machine fault feature extraction method based on FrFT-EWT principle

A technology of rotating machinery and fault characteristics, applied in the field of fault diagnosis of mechanical equipment, can solve problems such as large amount of calculation, lack of adaptive processing ability, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

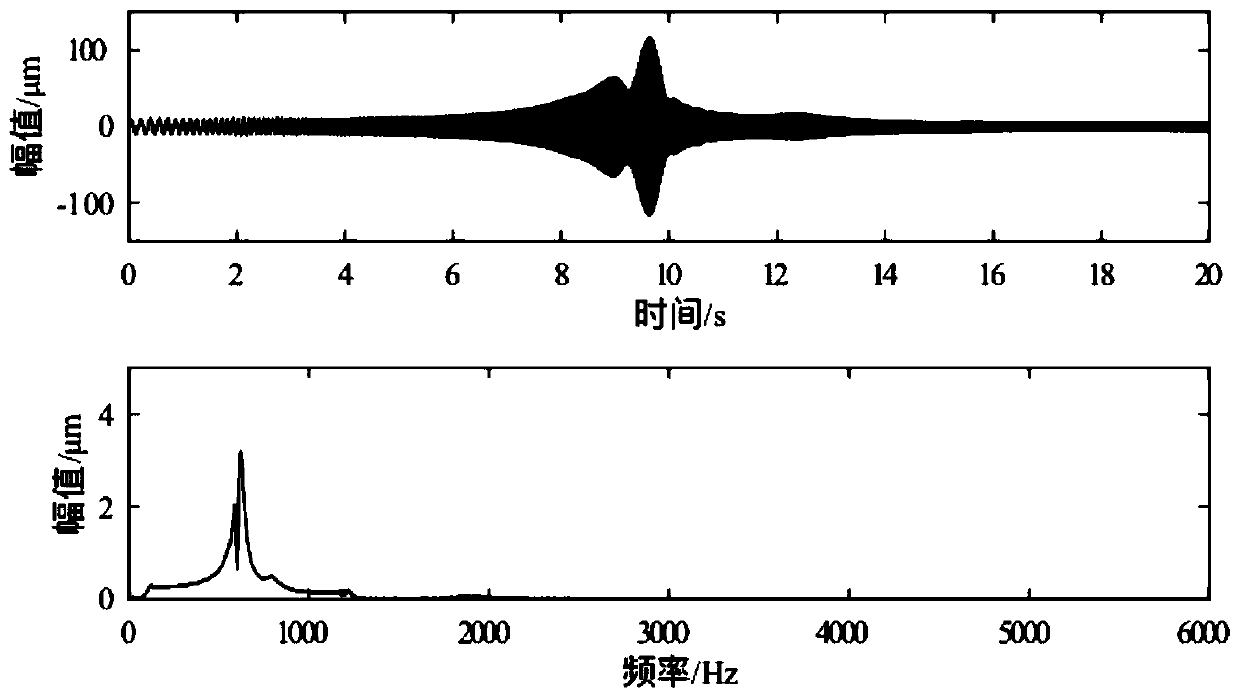

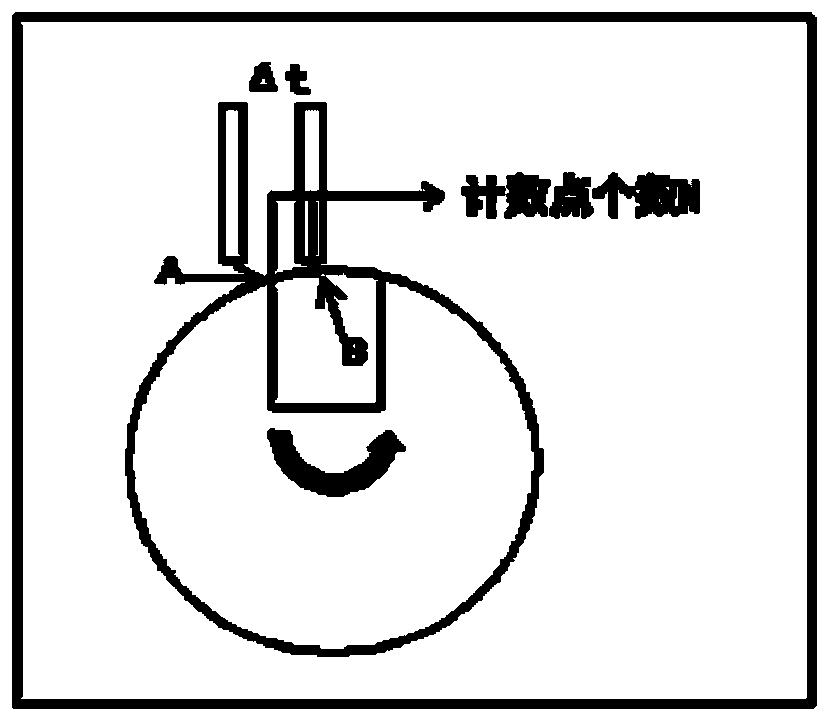

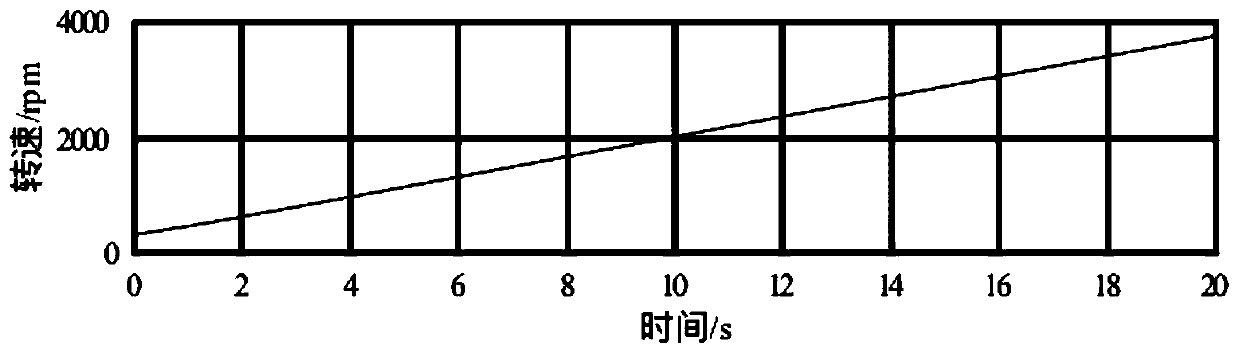

[0030] In the present invention, the rotating shaft is started once, the vibration and key phase signals are collected, and the average speed of each revolution in the starting process is calculated from the key phase signals to obtain the rotation speed sequence of the starting process. Then perform p on the vibration signal 1 Fractional Fourier transform processing under the order, and use empirical wavelet transform in the time-frequency domain to adaptively extract the 1-octave frequency component, high-octave frequency component and low-octave frequency component of the vibration signal. Use -p for 1-octave components 1 The fractional Fourier transform under the order can obtain the time-domain waveform of the 1-octave frequency component of the vibration signal. Then use p for the higher order components of the vibration signal 3 The fractional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com