In-situ water body micro-plastic graded sampling system

A graded sampling and microplastics technology, applied in the field of marine environment detection, can solve the problems of large sampling net size, poor accuracy of network port flowmeter, unclean washing, etc., to achieve convenient and simple collection work, accurate analysis and reliability, and avoid contamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

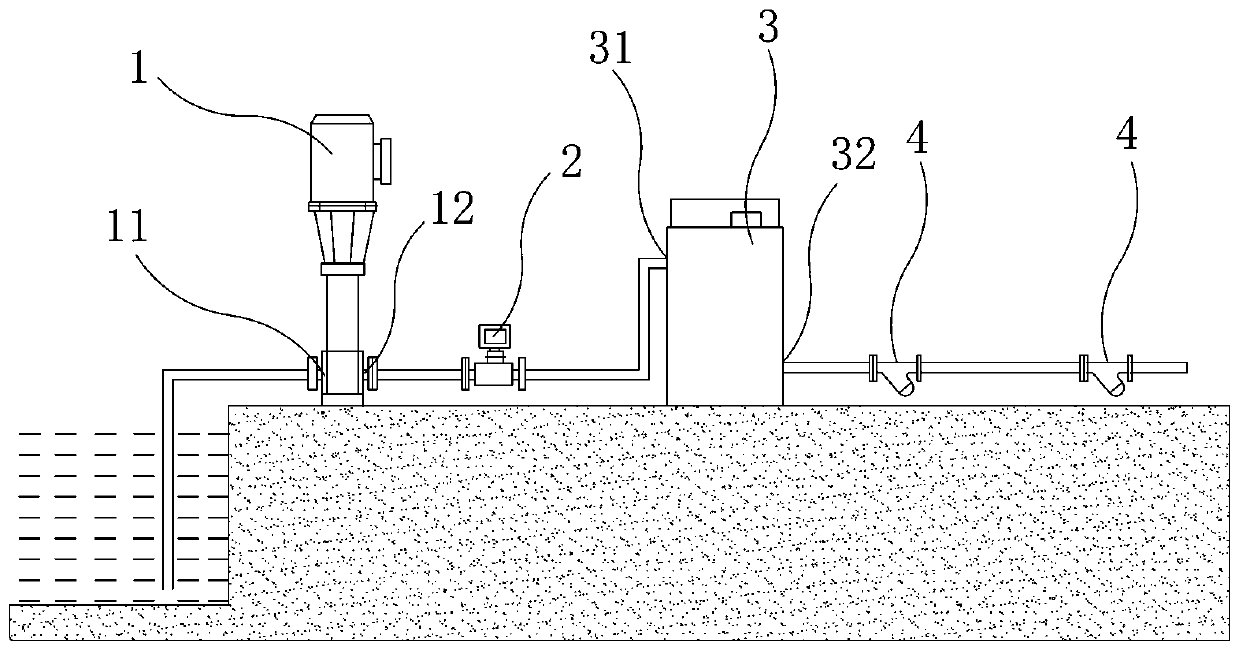

[0016] Such as figure 1 As shown, the present invention discloses an in-situ water body microplastics graded sampling system, which includes a water supply pump 1 with a water inlet 11 and a water outlet 12. The water port 12 is connected to the buffer barrel 3;

[0017] The flow meter 2 is set between the water supply pump 1 and the buffer tank 3, one end of which is connected to the water outlet of the water supply pump 1, and the other end is connected to the buffer channel 3;

[0018] The buffer barrel 3 is provided with a water inlet 31 and a water outlet 32, the water inlet 31 of the buffer barrel 3 is connected to the flowmeter 2, and the water outlet 32 of the buffer barrel 3 is connected with at least two filters 4 arranged in sequence. The buffer bucket 3 is used to adjust the water volume, thereby adjusting the filtering speed.

[0019] When in use, the water inlet of the water supply pump 1 is connected to a pipeline, and the pipeline is even put into seawater,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com