A cross-section wood molding polishing device that is pulled and adsorbed by centrifugal pressing in the form of a cone

A technique of polishing device and wood molding, which is applied in the direction of grinding/polishing safety device, surface polishing machine tool, grinding/polishing equipment, etc. It can solve the problems of affecting the working environment, difficult to collect, limited adsorption area, etc., to prevent equipment The effect of shaking, increasing the adsorption area, and strengthening the collection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

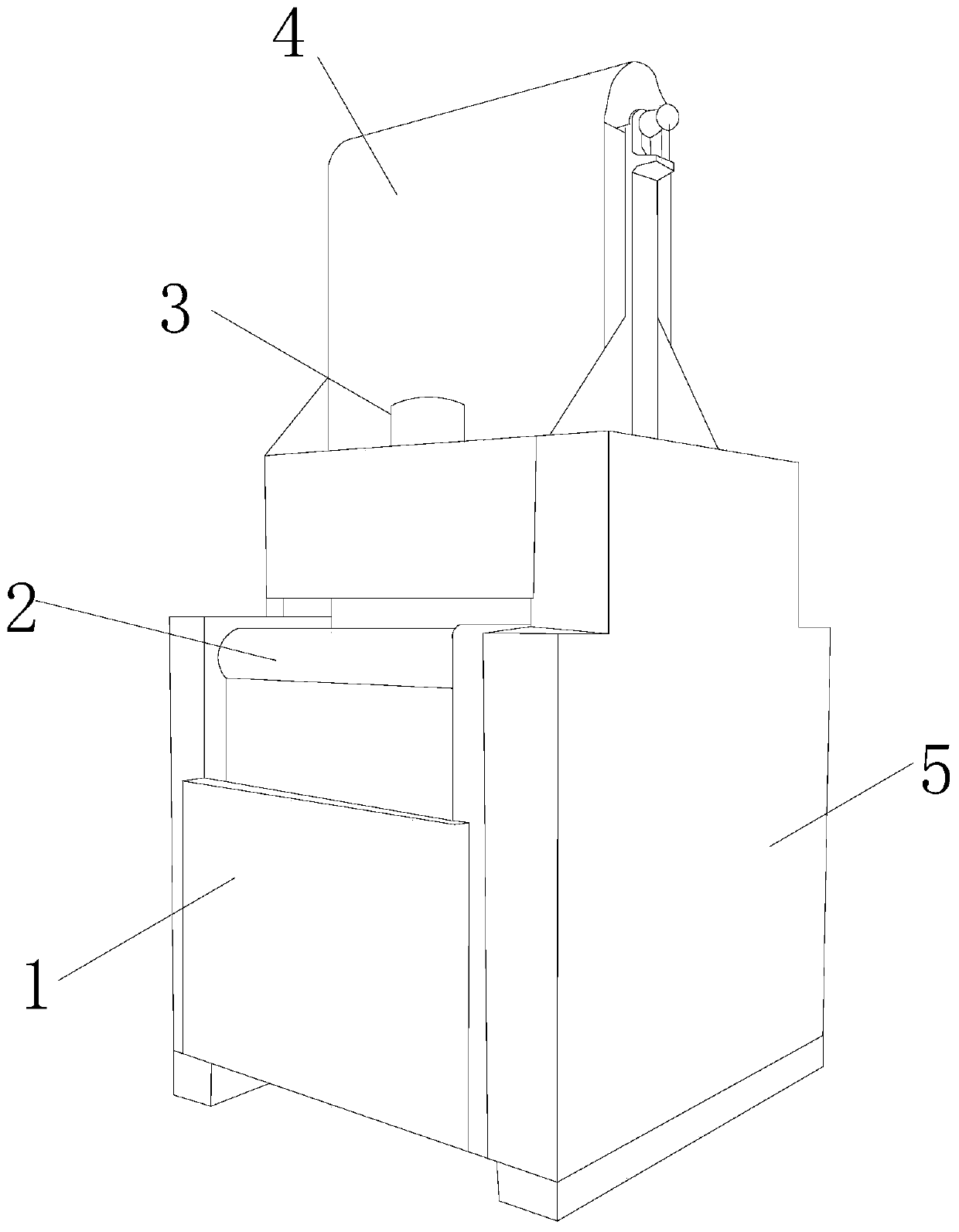

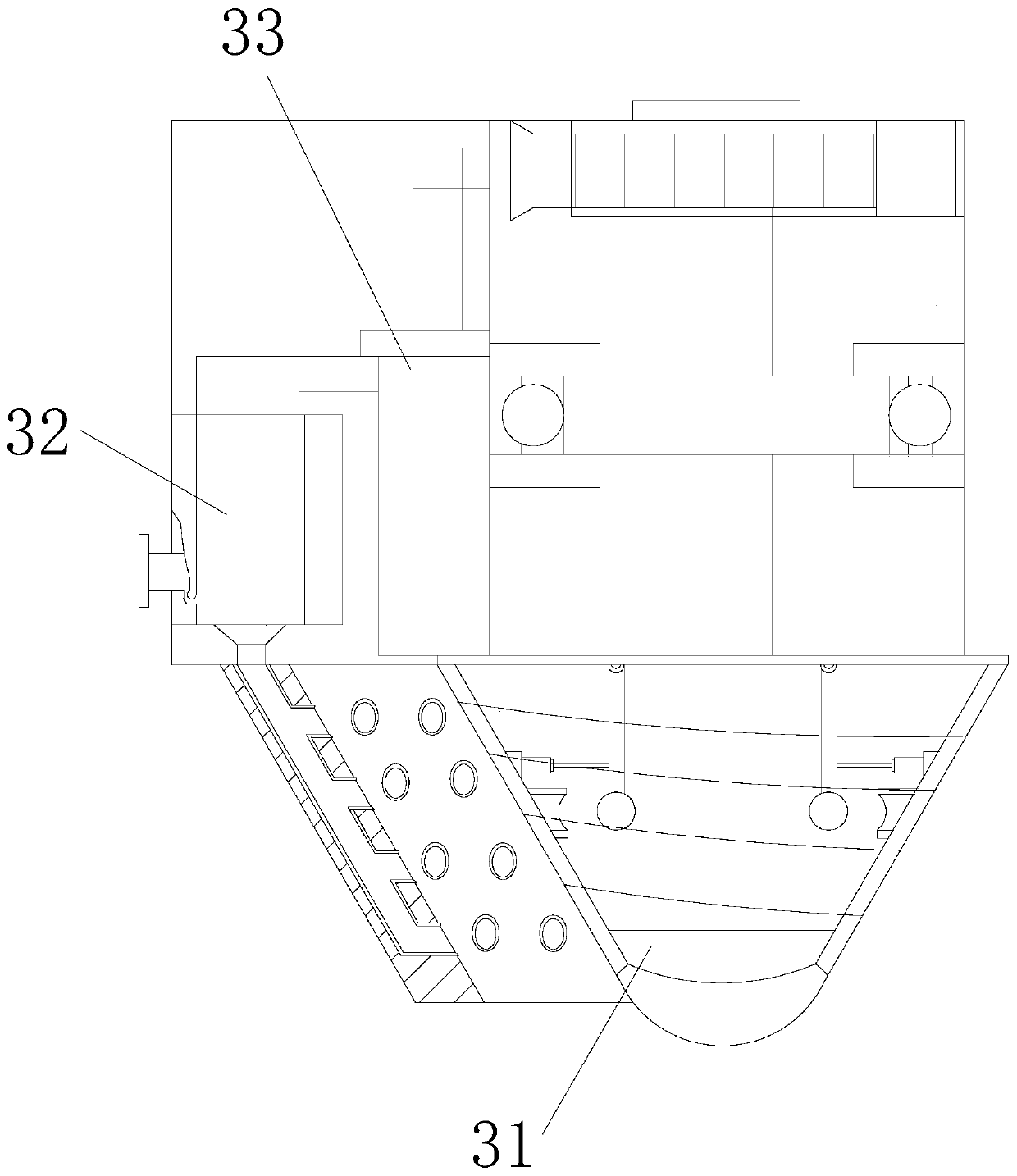

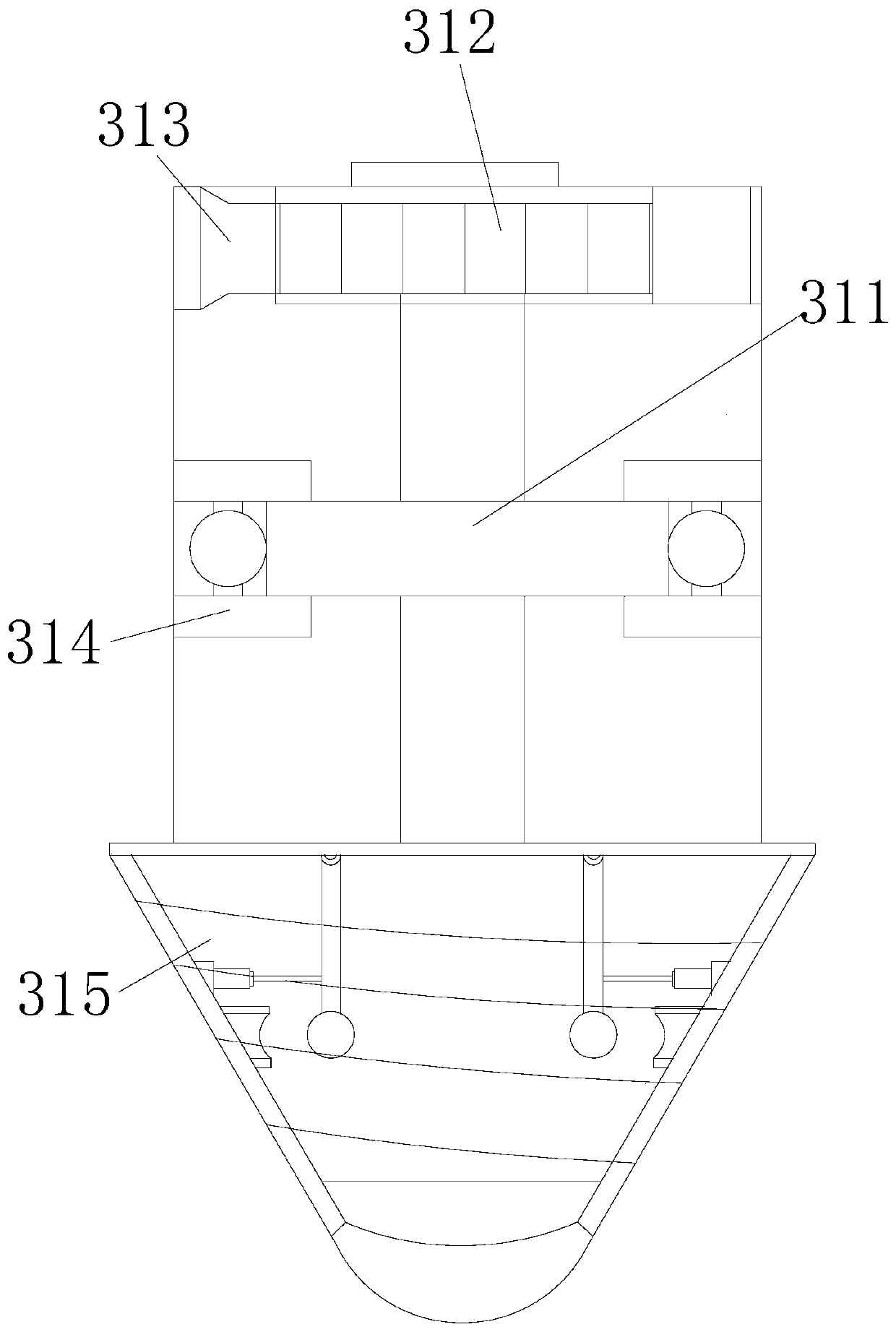

[0028] see figure 1 , the present invention provides a cross-sectional wood molding polishing device through centrifugal pressing, traction and adsorption in the form of a cone, the structure of which includes: a dust accumulation chamber 1, an input frame 2, an intelligent polishing device 3, a lifting platform 4, and a device housing 5. The input frame 2 is located at the front end surface of the device housing 5 and is connected with the device housing 5 by means of roller rolling clearance fit, and the dust accumulation chamber 1 is arranged under the front end surface of the device housing 5 and is installed in an embedded manner at the same time. The front end surface of the device housing 5, the lifting table 4 is arranged on the upper side surface of the device housing 5 and is screwed with the device housing 5 by a threaded plate fixing mode, and the intelligent polishing device 3 is embedded in the lifting table 4 The interior is fixedly connected with the lifting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com