MEMS piezoelectric ultrasonic transducer with acoustic tube

A piezoelectric ultrasonic and transducer technology, which is applied in the direction of electrostatic sensors, sensors, electrical components, etc., can solve the problems of limited pMUT energy conversion efficiency, etc., to improve the utilization rate of sound energy, increase the power of sound radiation, and increase the sound pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

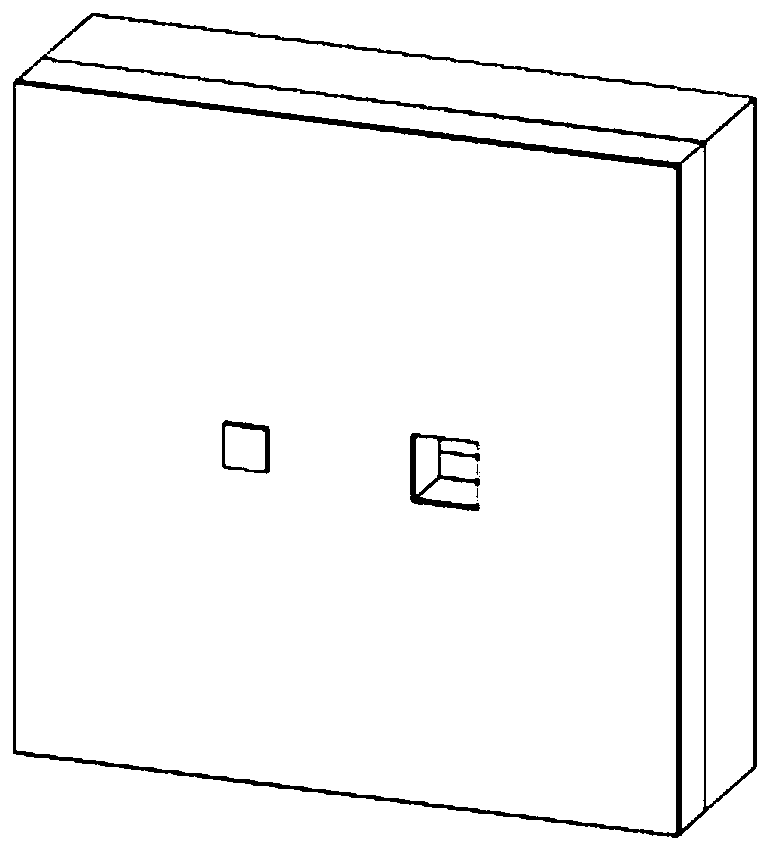

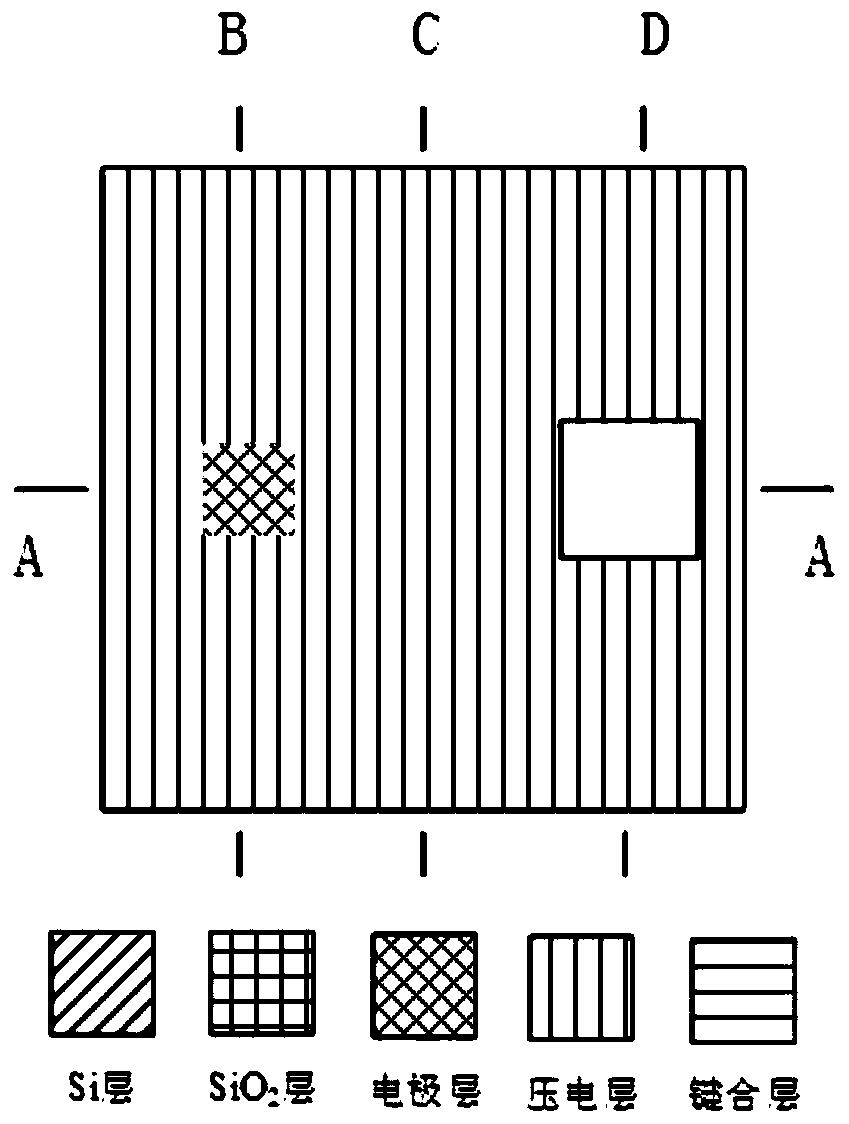

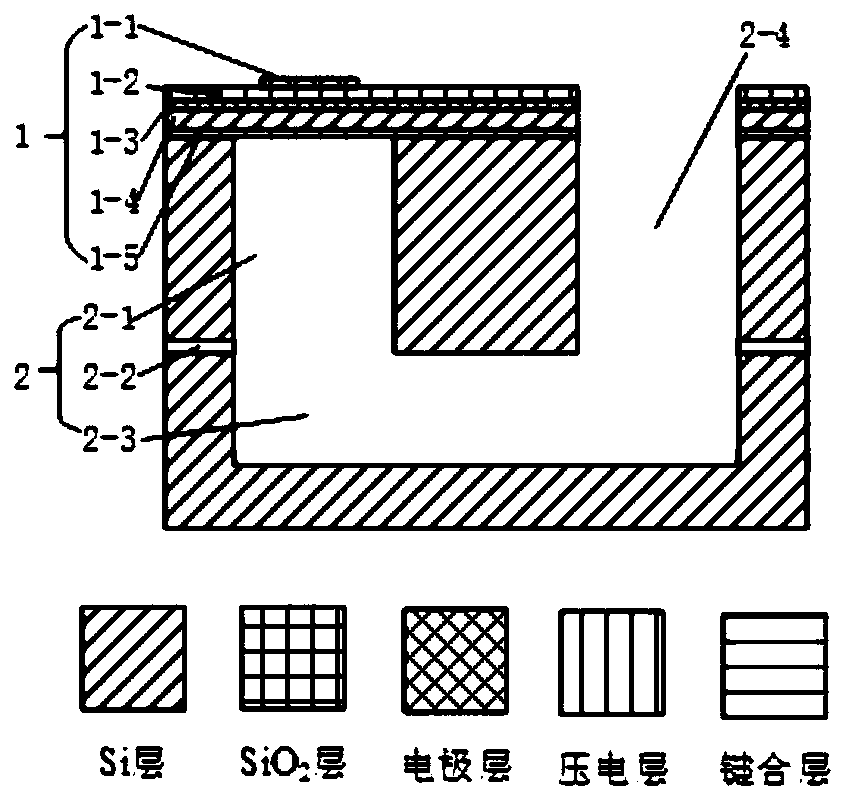

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] When a pMUT vibrates, it generates sound waves in opposite phases at the top and back simultaneously, but in a conventional pMUT, only half of the sound waves are utilized, and the sound waves generated at the back are wasted. By designing the pipeline structure to lead the sound generated from the back of the pMUT to the top, and recombining it with the sound generated at the top to radiate, the utilization rate of the sound generated by the pMUT can be greatly improved. Acoustic tubes are widely used in various musical instruments to amplify sound or tune sound waves. When the sound tube is set on the sound source, the sound tube is equivalent to the acoustic transmission line. According to the acoustic transmission line theory, adding a tube with a length of 1 / 4 odd multiples of the wavelength in front of the sound source can enhance the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com