Umbrella-shaped uniform distributing machine for grains in grain tank

A technology of distributing device and grain, which is used in cutters, agricultural machinery and implements, applications, etc., can solve the problems of frequent grain unloading, increased auxiliary time, inability to fully utilize and utilize the effective volume of grain tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

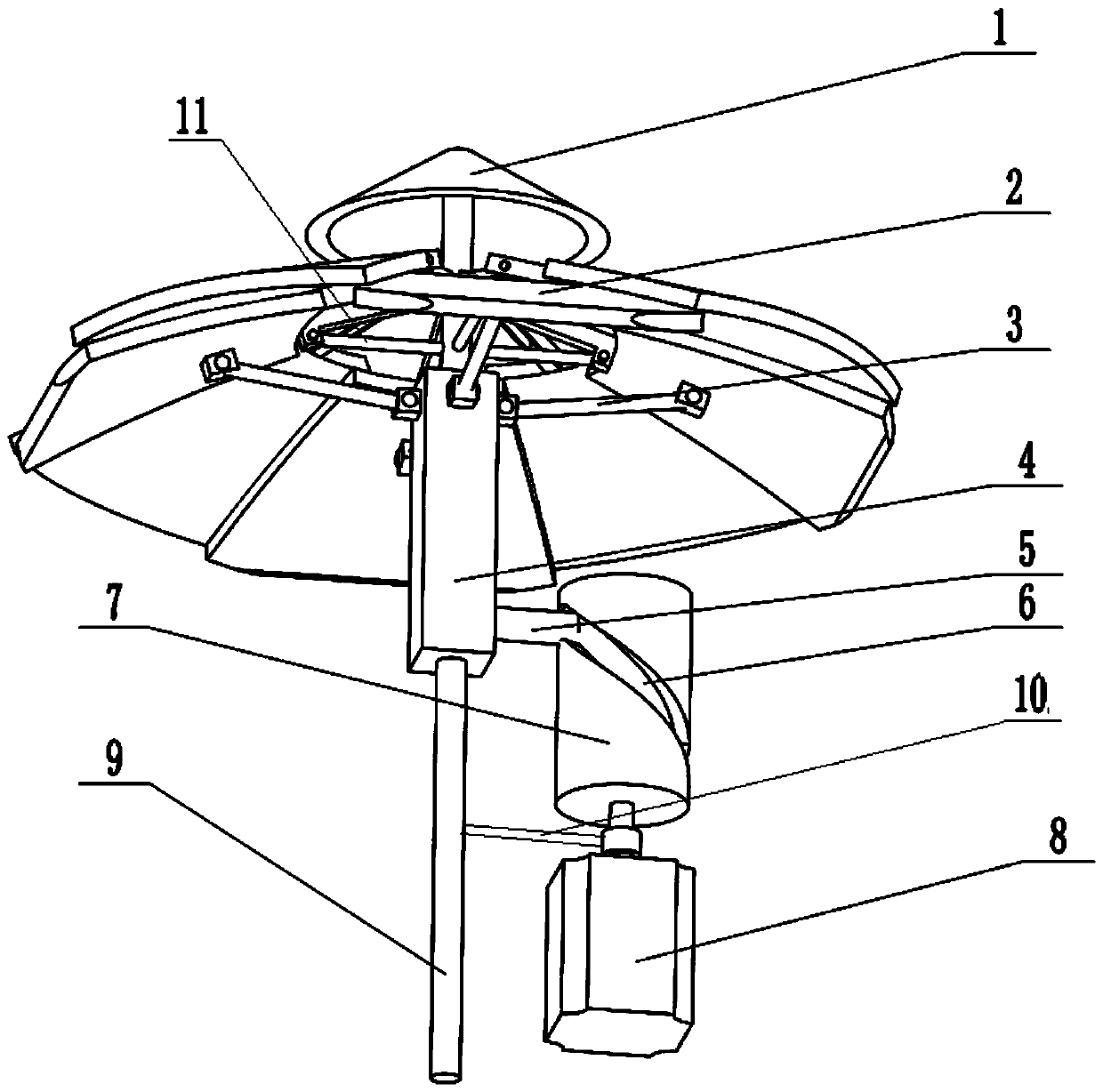

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An umbrella-shaped uniform distributor for grains in a grain tank, in which a conical cap 1 is installed on the top end of a column frame 9, and on the outside of the upper side of the column frame 9, the portion below the conical cap 1 is evenly distributed and fixed along the circumferential direction. Install a plurality of hanging struts 11, and fan-shaped evenly distributed deflectors 2 are respectively hingedly installed on the outer ends of the plurality of hanging struts 11. On the outside of the column frame 9, the multiple hanging Circumferentially and radially positioned at the lower side of the pole 11, the sliding sleeve 4 is movably set in the axial direction, and a plurality of supporting and adjusting drive rods 3 with the same number as the hanging pole 11 are connected with the sliding sleeve 4 and the corresponding two ends respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com