Intelligent grading gangue separator

An intelligent and gangue technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of poor system reliability, high production cost, and difficult construction, so as to save the space occupied by equipment, reduce civil construction investment, improve The effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

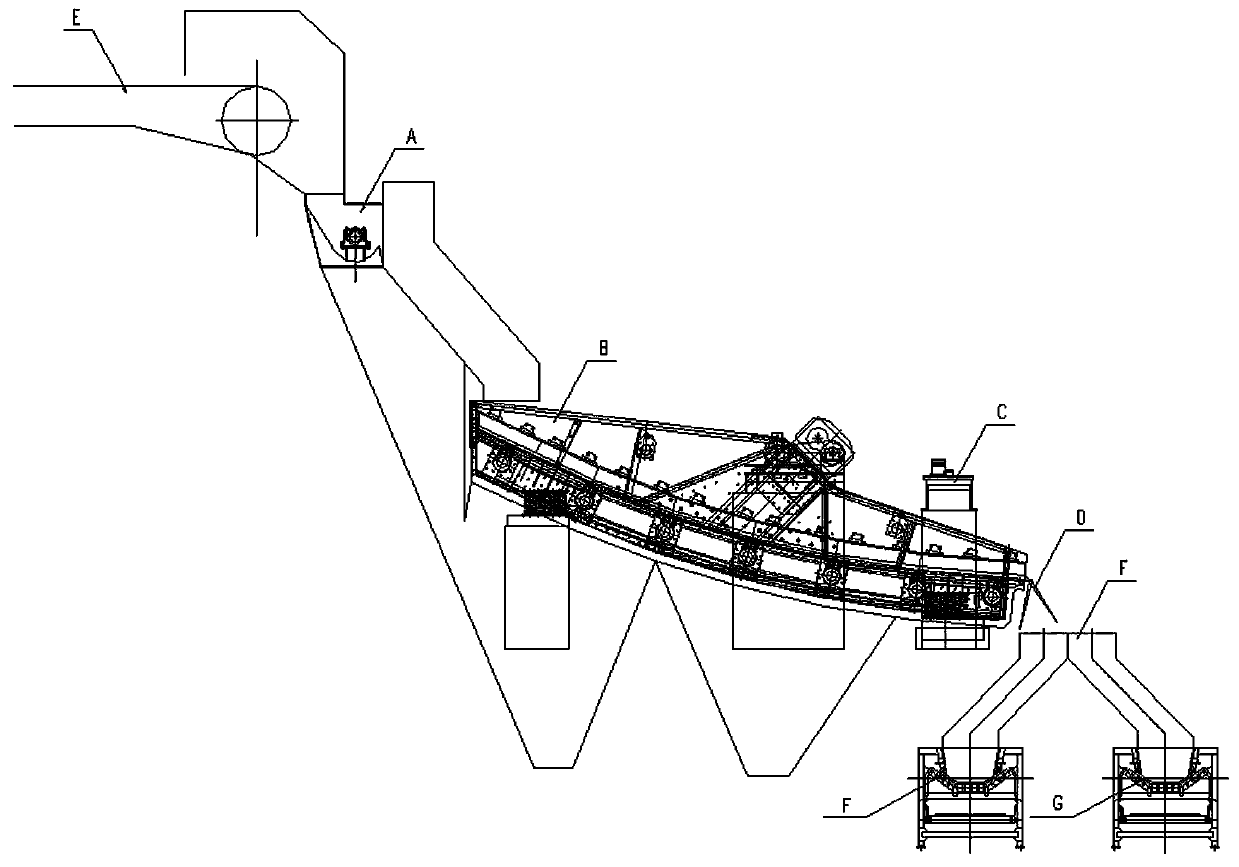

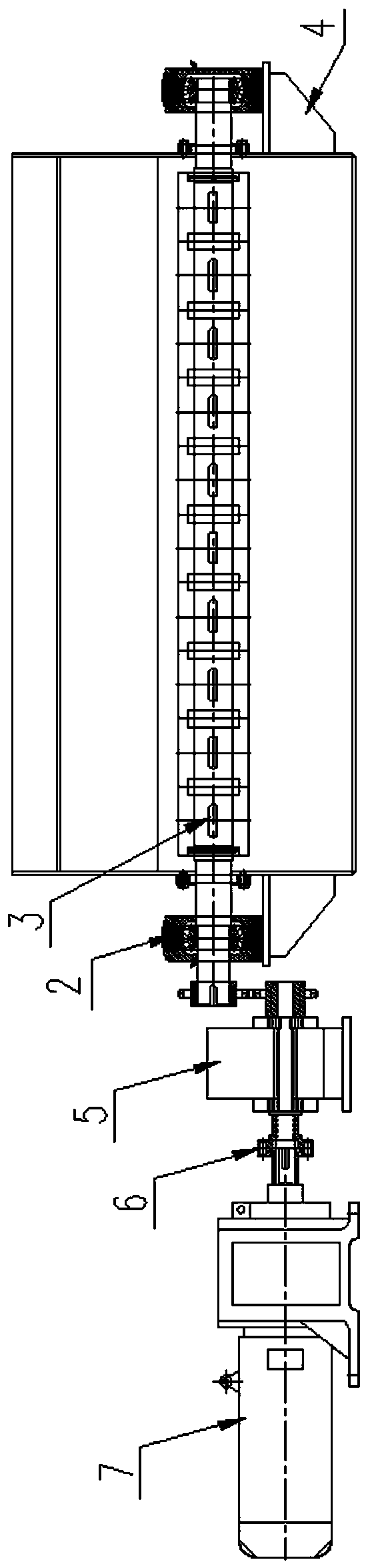

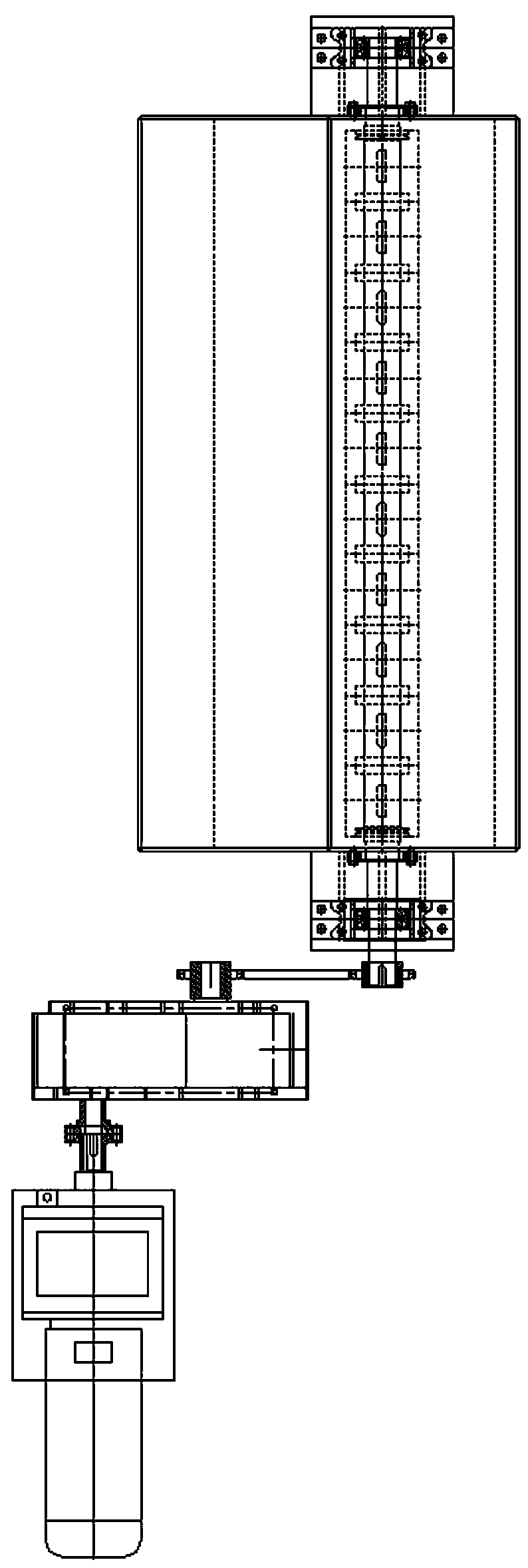

[0022] As shown in the figure, the intelligent graded gangue sorting machine is composed of agitating coal feeder A, graded gangue picking screen B, coal and gangue automatic identification system C, and gangue sorting flap D. The outlet of the coal machine corresponds, the outlet of the agitating coal feeder A corresponds to the inlet of the graded gangue screen B, and there is a "person" character coal and gangue separation chute F behind the graded gangue screen B, and the coal and gangue are automatically identified System C is set above the tail end of graded gangue screen B, and under the control of coal and gangue automatic identification system C, it can send coal and gangue into the coal chute and gangue chute of "person" character coal and gangue separation chute F respectively. The gangue-selecting flap D is arranged at the tail end of the graded gangue-picking screen B, and the coal chute and the gangue chute lead to the coal conveyor belt G and the gangue conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com