A kind of tvs chip glass passivation screen printing screen plate and its process method

A technology of glass passivation and screen printing, which is applied to screen printing machines, printing machines, printing machines, etc., and can solve problems such as incomplete groove printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be further described below with reference to the examples and drawings:

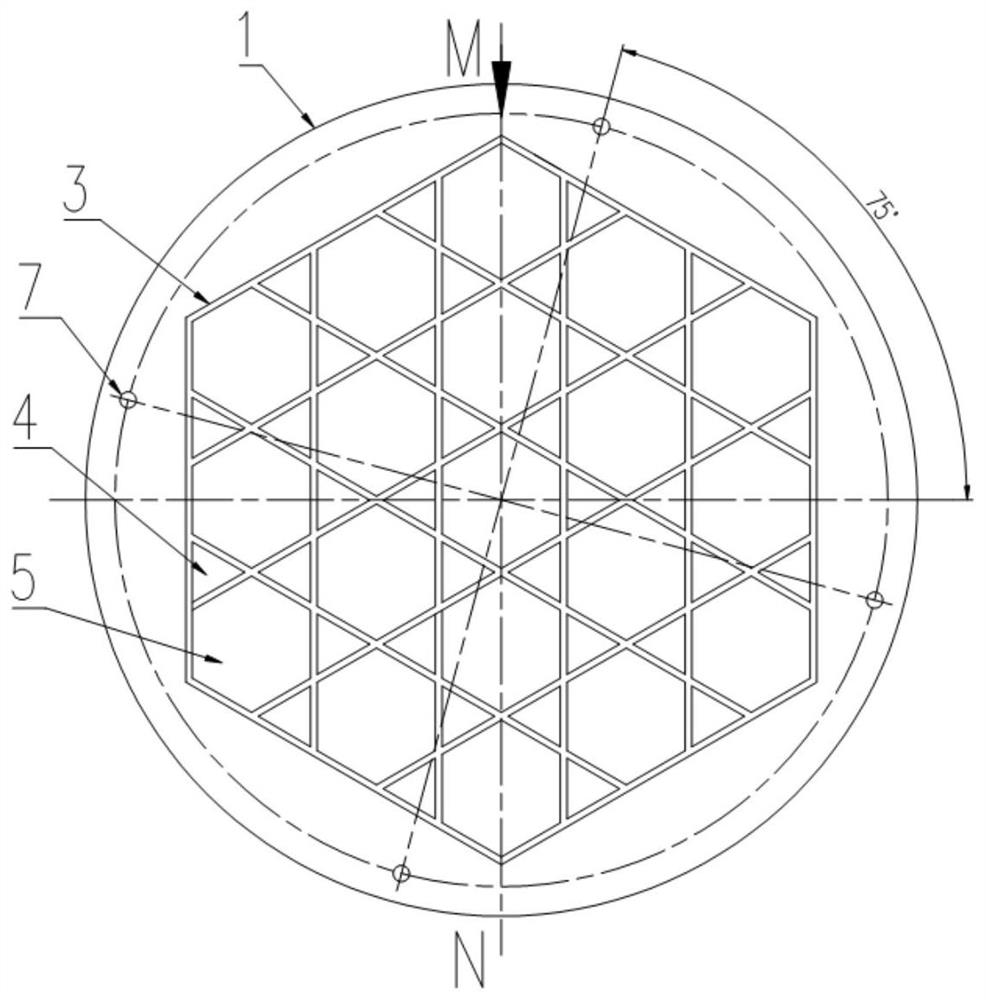

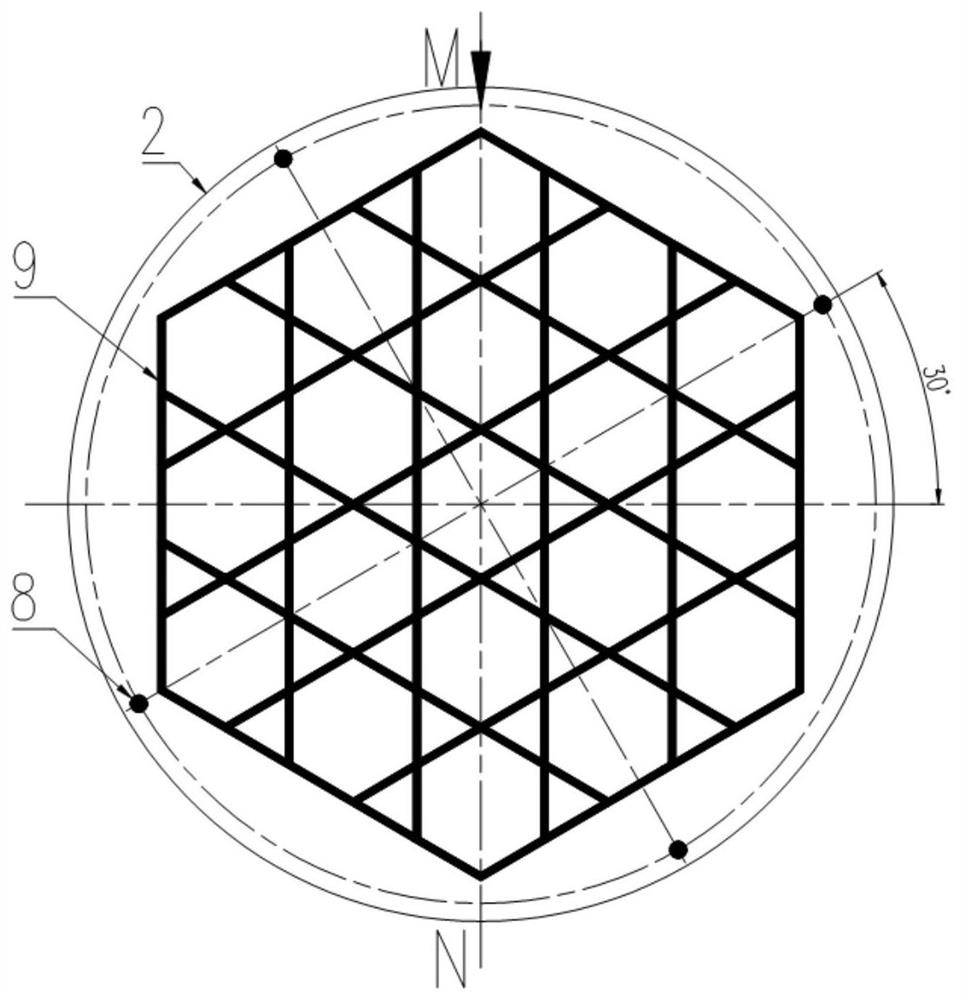

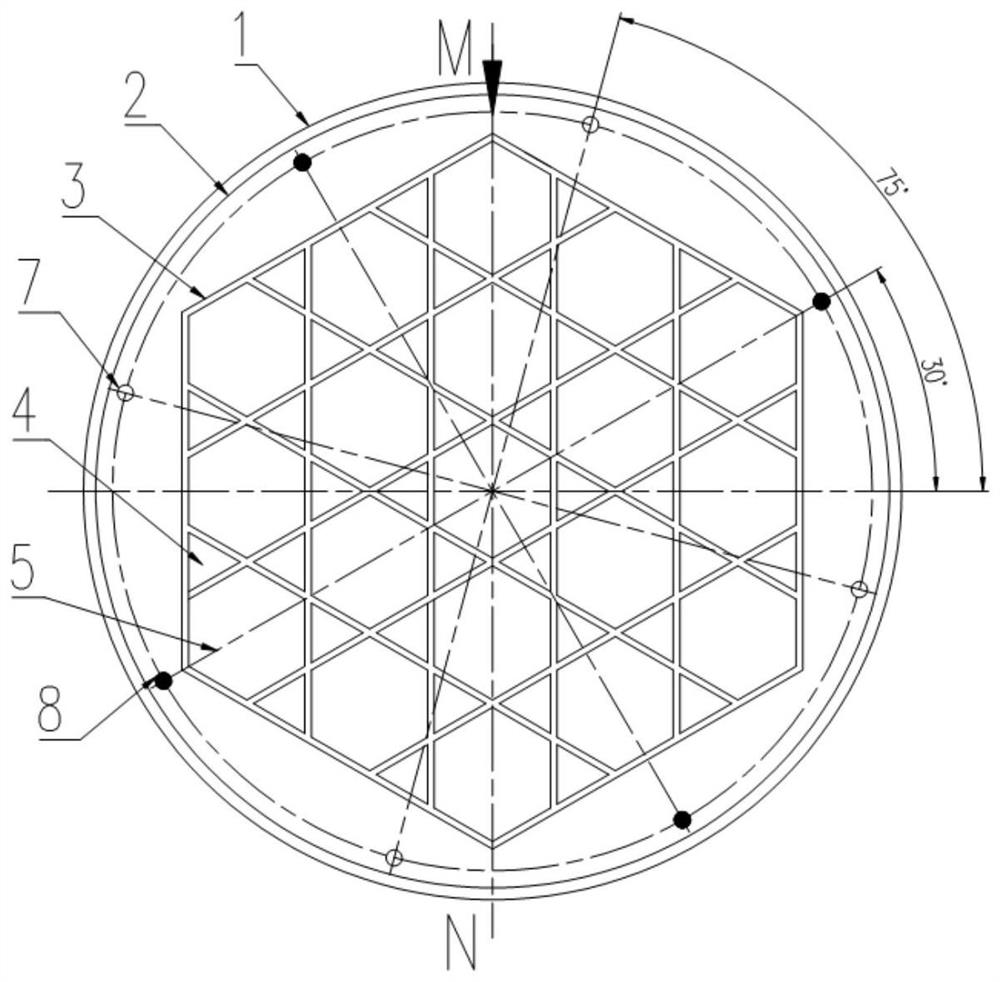

[0030]TVS chip glass passivation screen printing net plate, such asfigure 1 As shown, the printing net version 1 includes several two two-two-mutually cross-crossing channels 3, and the intersection is not coincident, and the channel 3 is two two mutually intersecting to form a positive hexagonal effective area, that is, the TVS chip 5, any adjacent adjacent The positive hexagon is connected to a single top connection, any adjacent three positive hexagonal connection vertices encloses a positive triangle invalid zone 4, and all channel 3 two two mutual intersections are interrupted. This structure causes all positive hexagonal TVS chip 5 in parallel, all of which are seamlessly grounded on the channel 3, minimizing the number of inflection points. At the same time, the printing screen 1 also includes four Mark points 7, which is evenly disposed on the circumference of the edge of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com