High-speed paper folding machine

A folding machine, high-speed technology, applied in the direction of folding thin materials, separating objects, packaging, etc., can solve the problems of dispersion, long-term cooperation, complex mechanism, etc., and achieve the effect of shortening the running stroke and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

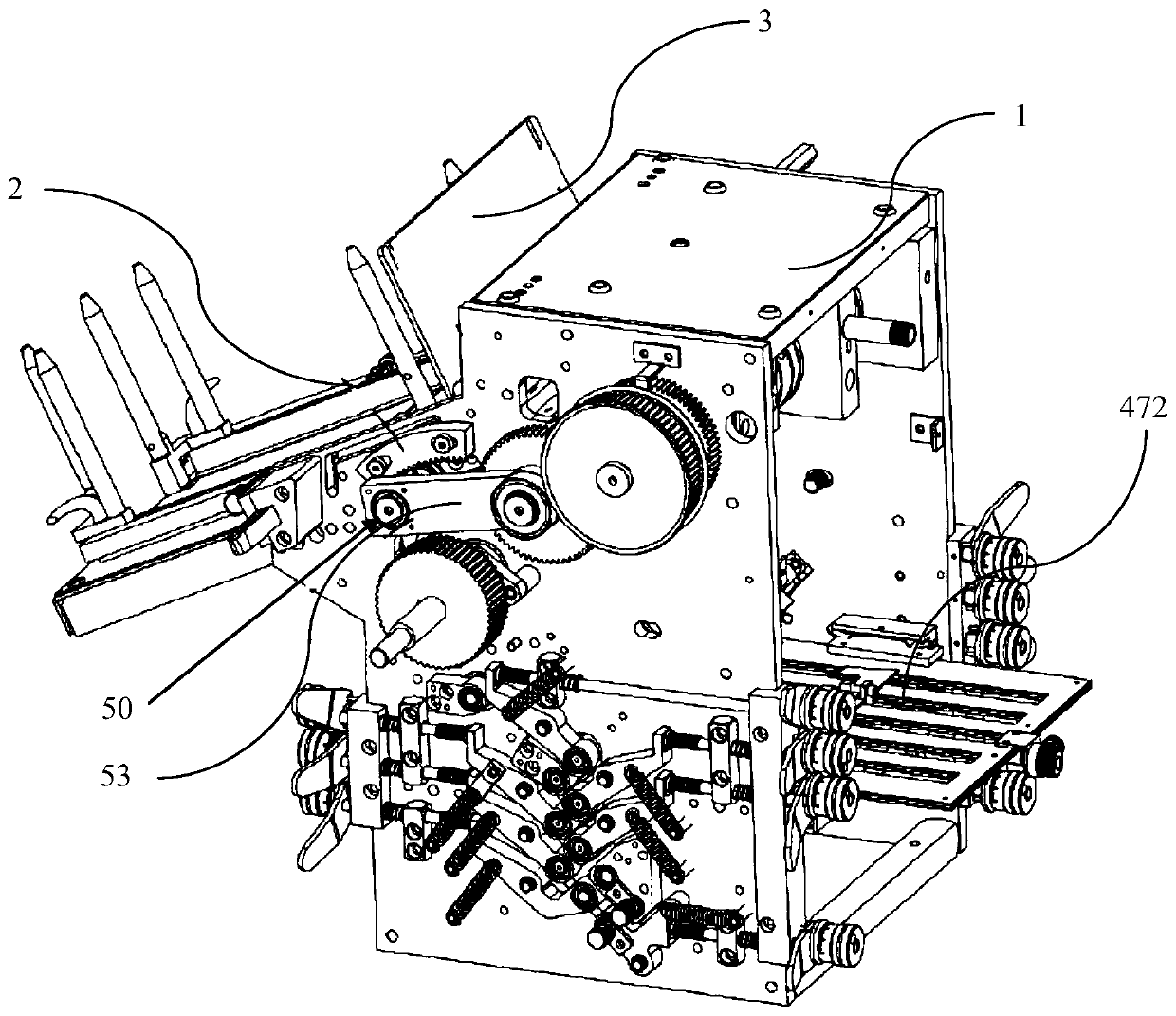

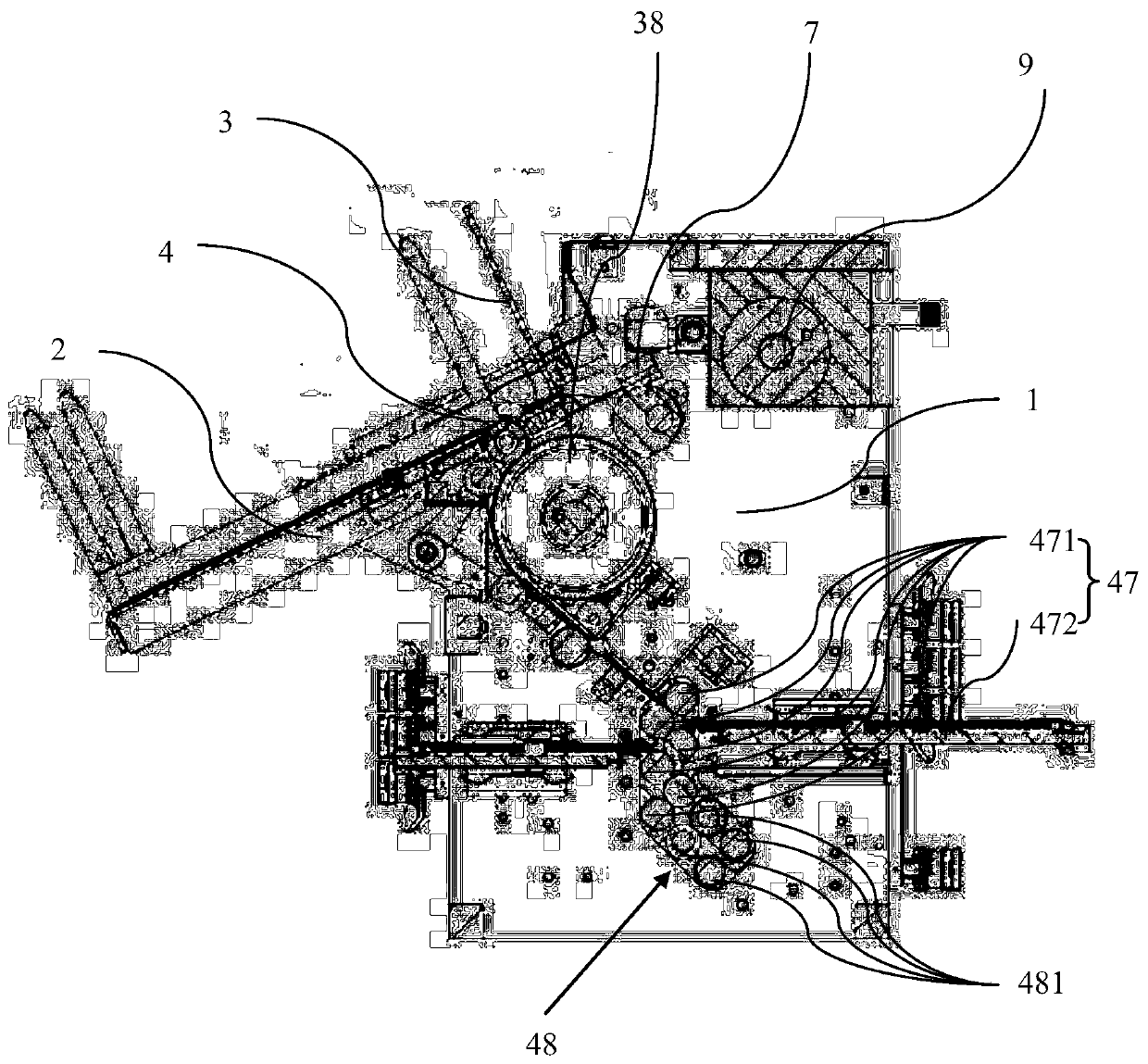

[0027] Embodiment one: if Figure 1-Figure 8 As shown, a high-speed folding machine includes a frame 1, a stacker 2 and a paper suction mechanism, and a paper stopper 3 is arranged above the inner edge of the stacker 2, and the stopper 3 and the stacker 2 are perpendicular to each other. Set, the paper pile table 2 is used to place the paper pile, that is, the drug instructions to be folded; the paper suction mechanism includes a negative suction roller 4, and the negative suction roller 4 is located below the paper blocking tray 3, and the bottom of the paper blocking tray 3 is provided with a plurality of The air jet hole 5 for separating the bottom paper from the upper paper, the negative suction roller 4 is provided with a plurality of suction holes 6 for sucking the bottom paper, and the blower is set between the paper blocking plate 3 and the negative suction roller 4 Air propeller 7, air blowing propeller 7 is provided with blowing holes (not shown) for separating botto...

Embodiment 2

[0032] Embodiment two: other structures are identical with embodiment one, and its difference is: as Figure 9 with Figure 10 As shown, the negative suction roller 4 includes a hollow suction pipe 40, one end of the suction pipe 40 is closed, and the other end of the suction pipe 40 is connected to the first air inlet through a trachea (not shown in the figure), on the suction pipe 40 A plurality of first paper suction holes 41 are arranged at intervals, and a plurality of suction rings 42 and a plurality of pressure paper bearings 43 are set on the suction pipe 40, and a pressure paper bearing 43 is arranged between two adjacent suction rings 42 , the suction ring 42 corresponds to the first paper suction hole 41 one by one, the suction ring 42 is provided with a second paper suction hole 44, and the second paper suction hole 44 and the first paper suction hole 41 are arranged opposite to each other, each group The first paper-absorbing hole 41 and the second paper-absorbin...

Embodiment 3

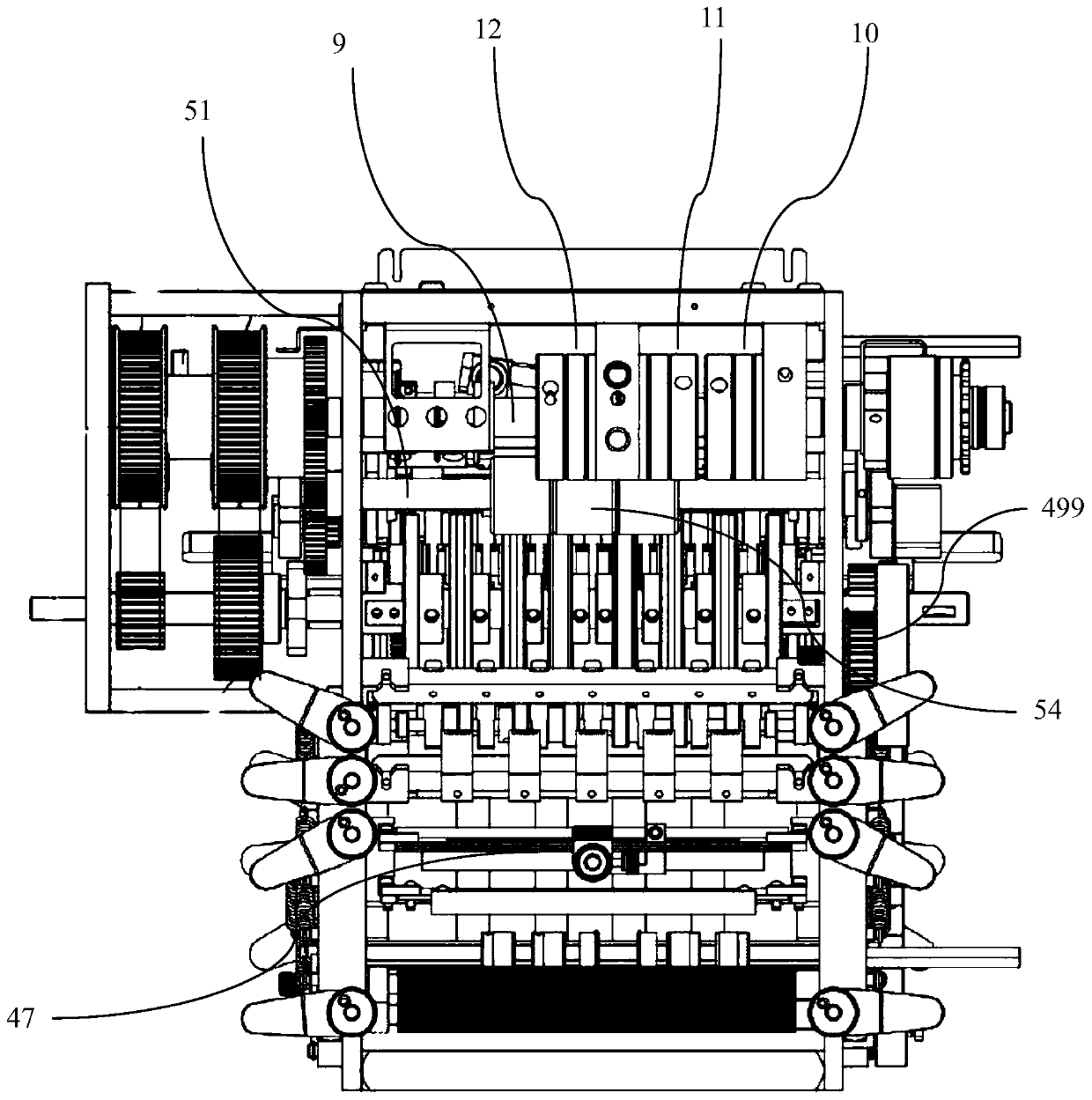

[0034] Embodiment 3: other structures are the same as Embodiment 2, the difference is that: a folding mechanism 47 and an output mechanism 48 are arranged in the frame 1, and a folding origami transmission mechanism 49 is arranged on the outside of the frame 1, and the folding origami mechanism 47 includes six origami glues The roller 471 and the origami plate 472 maintain a corresponding gap between the two adjacent origami rubber rollers 471, and the axis connection of the three adjacent origami rubber rollers 471 is V-shaped, forming two V-shaped origami rubber rollers 471 There is a paper folding board 472 between them, and the output mechanism 48 includes four conveying rubber rollers 481. The conveying rubber rollers 481 are arranged vertically and staggeredly below the folding paper rollers 471. The mechanism 49 drives the conveying rubber roller 481 to rotate to send the folded instruction manual out of the frame 1 .

[0035]In this specific embodiment, the negative su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com