Polycarboxylate superplasticizer based on phenyl hydroxyl block modification

A technology of phenylhydroxyl block and polycarboxylic acid, which is applied in the field of building materials and achieves the effects of good stability, increased water reduction rate and good shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

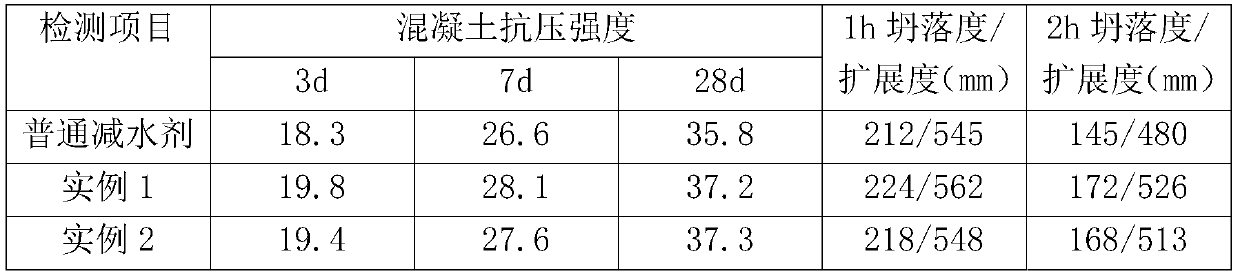

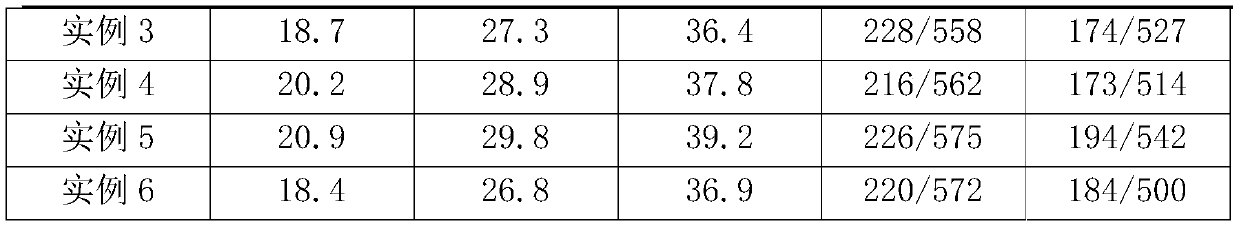

Examples

Example Embodiment

[0022] Example 1:

[0023] A polycarboxylic acid water reducing agent modified based on phenyl hydroxyl block, the total mass of raw materials is 1000 parts, the mass fraction is 40%, and it is mainly prepared from the following main components:

[0024] Styrene: 7 parts; Prenol: 8 parts; Composition of vinyl butyl ether polyoxyethylene ether and methallyl polyoxyethylene ether with a mass ratio of 1: 352 parts; Acrylic acid: 21 Parts; the composition of lauryl peroxide and dibenzoyl peroxide with a mass ratio of 1:1: 1.2 parts; azobisisobuimidazoline hydrochloride: 2.1 parts; mercaptoethanol: 1.4 parts; the rest are water.

[0025] Step (1): Preparation of phenyl hydroxy block polymer: add 7 parts of styrene and 8 parts of isopentenol into the No. ① reaction kettle, mix and stir uniformly, and add the initiator solution dropwise at a uniform rate at 45°C, namely 1.2 parts A mixture of the composition of lauryl peroxide and dibenzoyl peroxide with a mass ratio of 1:1 and 50 parts o...

Example Embodiment

[0027] Example 2:

[0028] A polycarboxylic acid water reducing agent modified based on phenyl hydroxy block, the total mass of raw materials is 1000 parts, the mass fraction is 40%, and it is mainly prepared from the following main components: 1-allyl-4-fluoro Benzene: 4 parts; Methacrylic alcohol: 7 parts; Vinyl butyl ether polyoxyethylene ether: 356 parts; Acrylic acid: 26 parts; Lauryl peroxide: 1.4 parts; Azobis with a mass ratio of 2:1 The composition of dimethyl isobutyrate and azobisisobuimidazoline hydrochloride: 2.4 parts; the composition of mercaptopropanol and mercaptoethanol with a mass ratio of 1:1: 1.2 parts; the rest is water.

[0029] Step (1): Preparation of phenyl hydroxy block polymer: add 4 parts of 1-allyl-4-fluorobenzene and 7 parts of methacrylic alcohol into the No. ① reaction kettle, mix and stir evenly, and at a constant speed at 50°C Drop the initiating liquid, which is a mixture of 1.4 parts of lauryl peroxide and 50 parts of deionized water, and the t...

Example Embodiment

[0031] Example 3:

[0032] A polycarboxylic acid water reducing agent modified based on phenyl hydroxy block, the total mass of raw materials is 1000 parts, the mass fraction is 40%, and it is mainly prepared from the following main components: the mass ratio is 1:2 1- The composition of allyl-4-fluorobenzene and 1-phenylvinylboronic acid: 3 parts; the composition of methacrylic alcohol and allyl alcohol with a mass ratio of 1:1: 8 parts; methallylpolyoxy Vinyl ether: 358 parts; acrylic acid: 24 parts; dibenzoyl peroxide: 1.6 parts; azobisisoheptanonitrile: 2.5 parts; mercaptopropanol: 1.5 parts; the rest is water.

[0033] Step (1): Preparation of phenyl hydroxy block polymer: 3 parts of a composition of 1-allyl-4-fluorobenzene and 1-phenylvinylboronic acid in a mass ratio of 1:2, 8 parts by mass The 1:1 composition of methacrylic alcohol and allyl alcohol was added to the No. ① reactor and mixed and stirred evenly, and the initiating liquid was added dropwise at a constant speed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap