Method for reducing volatile matter content in resin

A technology of volatile matter and measurement method, applied in the field of composite materials, can solve the problems that affect the subsequent use of resin, increase the viscosity of the system, and slowly increase the curing degree of the resin, and achieve high volatile matter removal efficiency, small impact on subsequent use, and simultaneous reduction. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

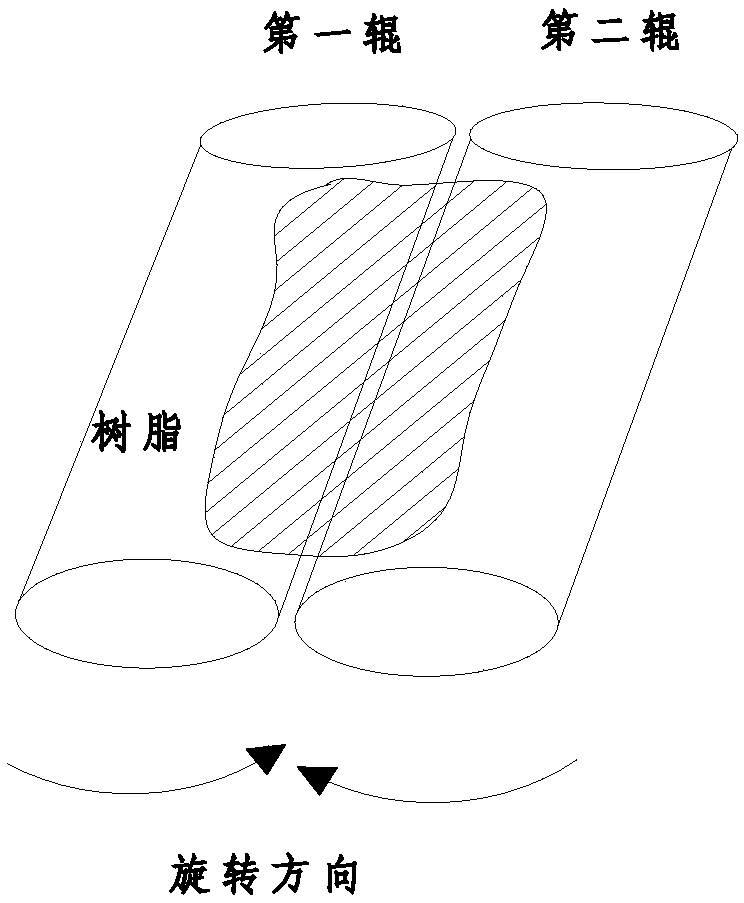

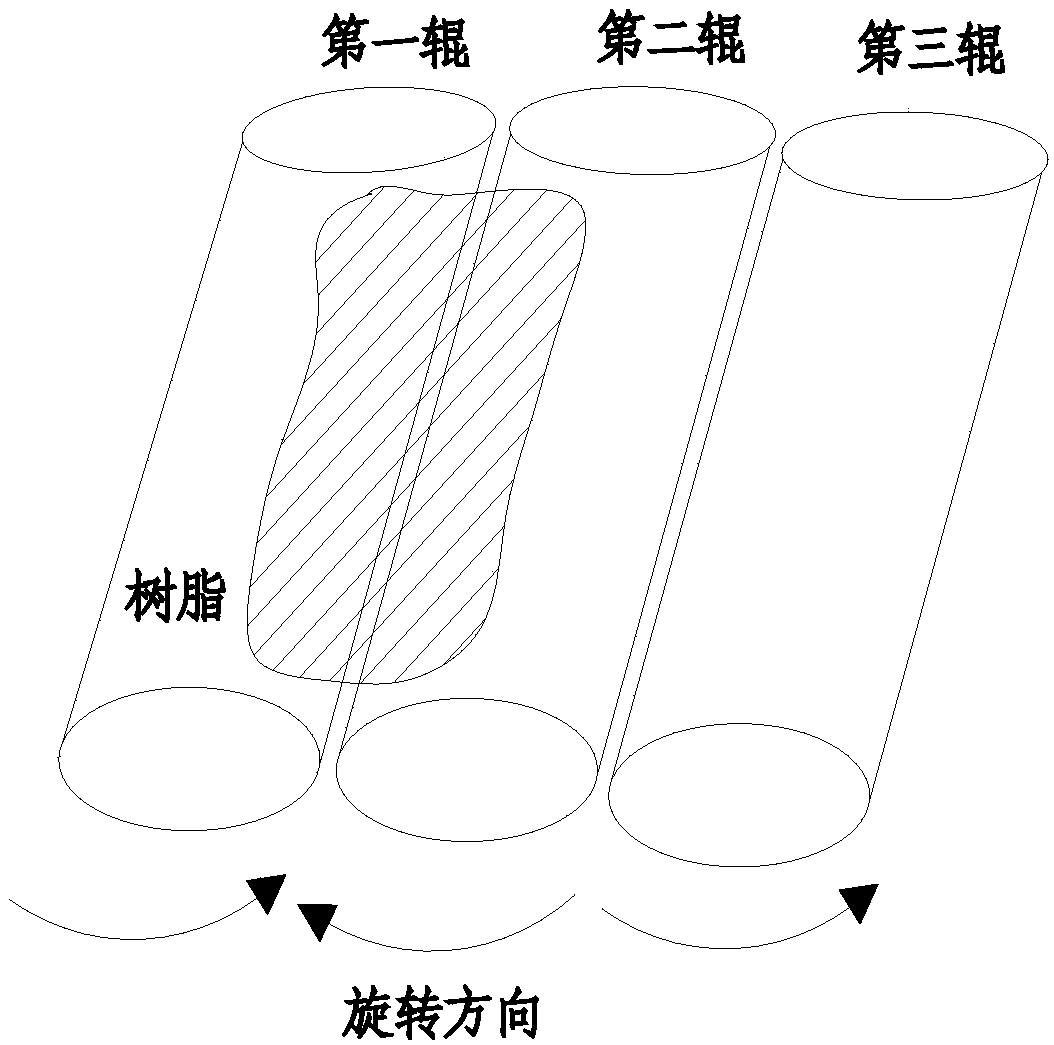

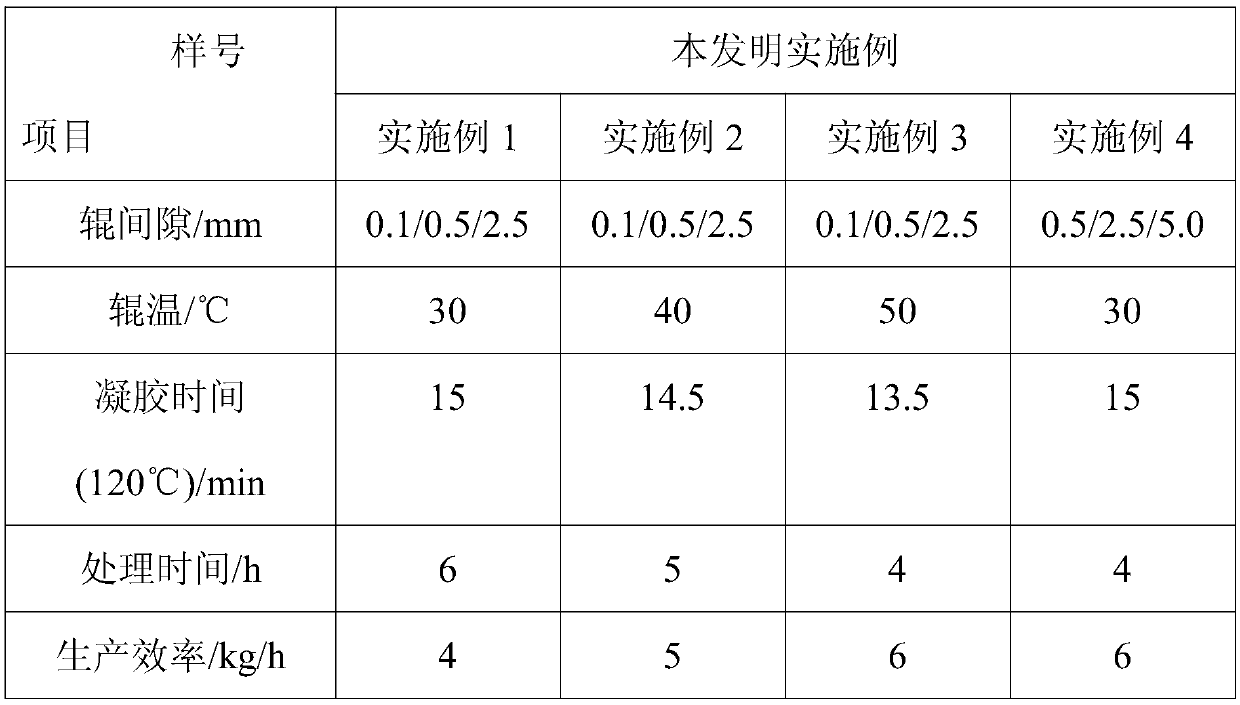

[0060] Step 1: Start the three-roll grinder, control the gap between the front roll and the second roll at 0.1mm, leave the scraper away from the surface of the rear roll, and slowly pour a certain amount of phenolic phenolic resin between the front roll and the second roll of the three-roll grinder, and the phenolic The amount of resin is to cover the gap and be flush with the highest point of the front roller;

[0061] Step 2: Test the volatile matter content of the resin every 30 minutes, and adjust the roller spacing according to the volatile matter content. The test method for the volatile content in phenolic resin is to take out 10-20g of phenolic resin, spread it flat on the measuring paper, and measure the mass as m1. Put the resin and weighing paper into an oven, set the temperature at 100°C, take it out after 10 minutes, and measure its mass as m2. The content of volatile matter in the resin is (m1-m2) / m1%. When the volatile content of resin is 30-40%, the distance...

Embodiment 2

[0065] Step 1: Start the three-roll grinder, control the gap between the front roll and the second roll at 0.1mm, leave the scraper away from the surface of the rear roll, and slowly pour a certain amount of phenolic phenolic resin between the front roll and the second roll of the three-roll grinder, and the phenolic The amount of resin is to cover the gap and be flush with the highest point of the front roller;

[0066] Step 2: Test the volatile matter content of the resin every 30 minutes, and adjust the roller spacing according to the volatile matter content. The test method for the volatile content in phenolic resin is to take out 10-20g of phenolic resin, spread it flat on the measuring paper, and measure the mass as m1. Put the resin and weighing paper into an oven, set the temperature at 100°C, take it out after 10 minutes, and measure its mass as m2. The content of volatile matter in the resin is (m1-m2) / m1%. When the volatile content of resin is 30-40%, the distance...

Embodiment 3

[0070] Step 1: Start the three-roll grinder, control the gap between the front roll and the second roll at 0.1mm, leave the scraper away from the surface of the rear roll, and slowly pour a certain amount of phenolic phenolic resin between the front roll and the second roll of the three-roll grinder, and the phenolic The amount of resin is to cover the gap and be flush with the highest point of the front roller;

[0071] Step 2: Test the volatile matter content of the resin every 30 minutes, and adjust the roller spacing according to the volatile matter content. The test method for the volatile content in phenolic resin is to take out 10-20g of phenolic resin, spread it flat on the measuring paper, and measure the mass as m1. Put the resin and weighing paper into an oven, set the temperature at 100°C, take it out after 10 minutes, and measure its mass as m2. The content of volatile matter in the resin is (m1-m2) / m1%. When the volatile content of resin is 30-40%, the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com