Preparation method of high internal-phase Pickering emulsion with stable egg white protein

A Pickering emulsion and egg white protein technology is applied in the field of emulsion preparation to achieve the effects of enhancing hydrophobicity, short duration and simple instrumentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Egg white pretreatment: Wash the fresh eggs with clean water, use an egg white separator to separate the egg white from the egg yolk, and remove the umbilical cord in the egg white. Then the egg white was stirred at a medium speed for 1 hour and then filtered through a 20-mesh sieve to obtain an egg white solution. The egg white protein solution was sonicated at an ultrasonic power of 400w for 15 minutes and then diluted with deionized water with a pH of 9 to a protein concentration of 5%. Stir slowly with magnetic stirring for 2h. Stand at 4°C for 24h.

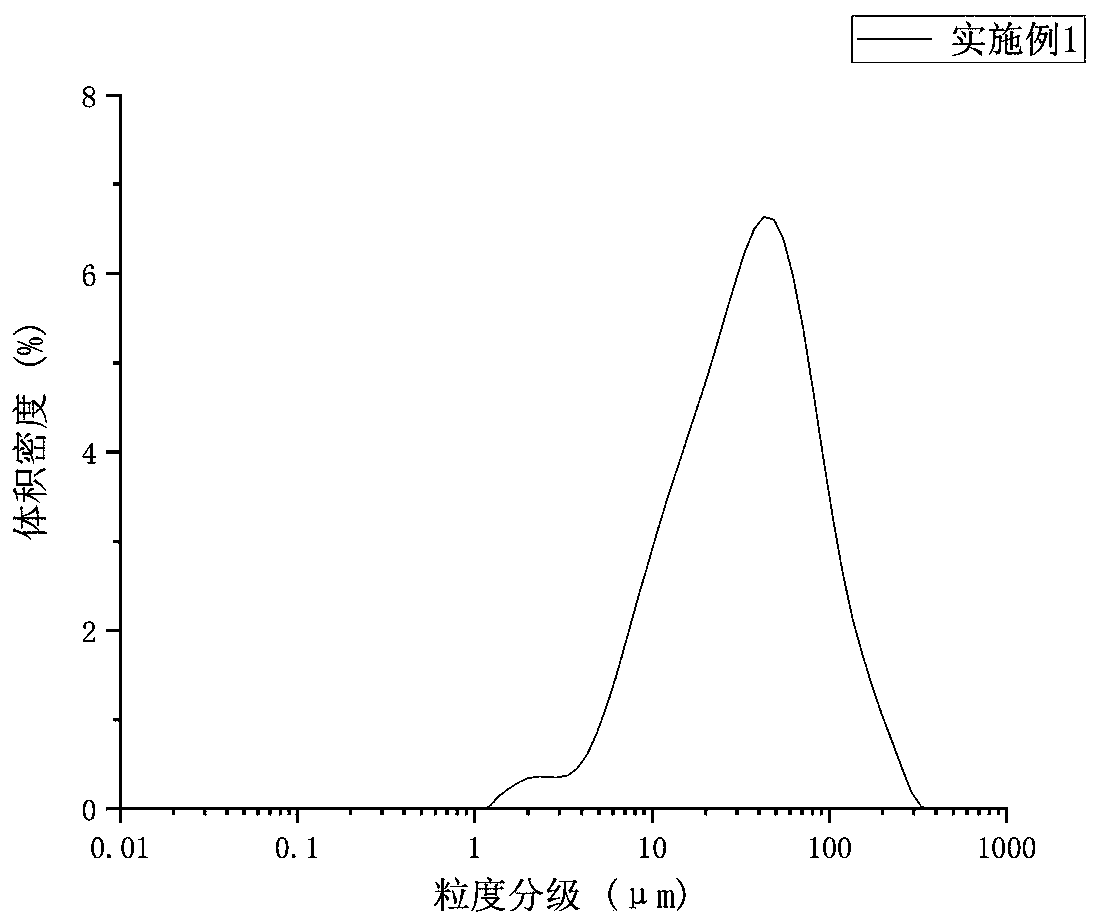

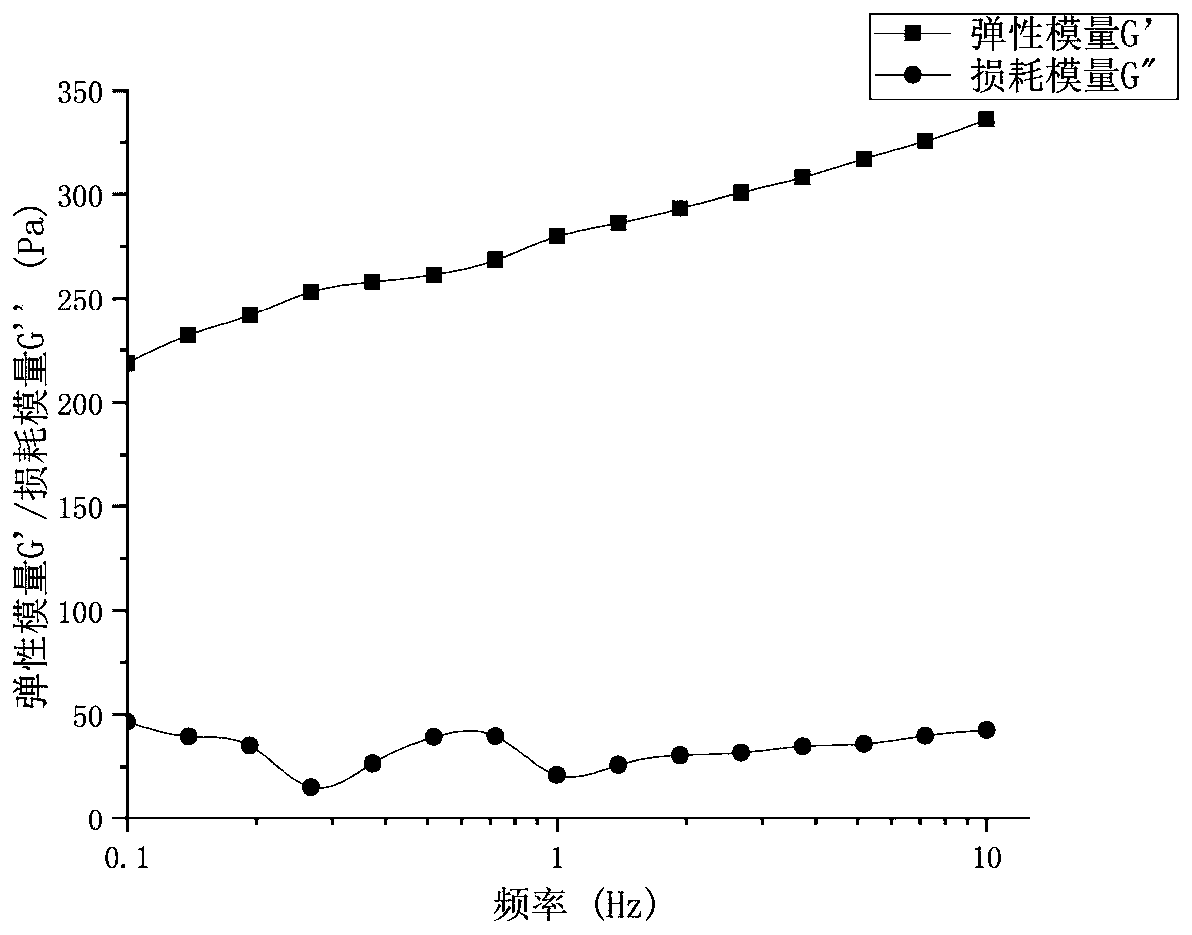

[0033] Step 3: Egg white protein was heat-treated in a water bath at 90°C for 40 minutes, then immediately ice-bathed, cooled and left to stand at 4°C for 24 hours to form an opaque gel. The gel was crushed, and the protein concentration was increased to 2% with deionized water. After pre-homogenization at 10,000 rpm for 2 min, ultrasonic crushing was performed at 400 w for 30 min to obtain a microgel dispers...

Embodiment 2

[0036] Step 1: Egg white pretreatment: Wash the fresh eggs with clean water, use an egg white separator to separate the egg white from the egg yolk, and remove the umbilical cord in the egg white. Then the egg white was stirred at a medium speed for 45 minutes and filtered through a 20-mesh sieve to obtain an egg white solution. The egg white protein solution was sonicated at an ultrasonic power of 400w for 15 minutes and then diluted with deionized water with a pH of 9 to a protein concentration of 5%. Stir slowly with magnetic stirring for 2h. Stand at 4°C for 24h.

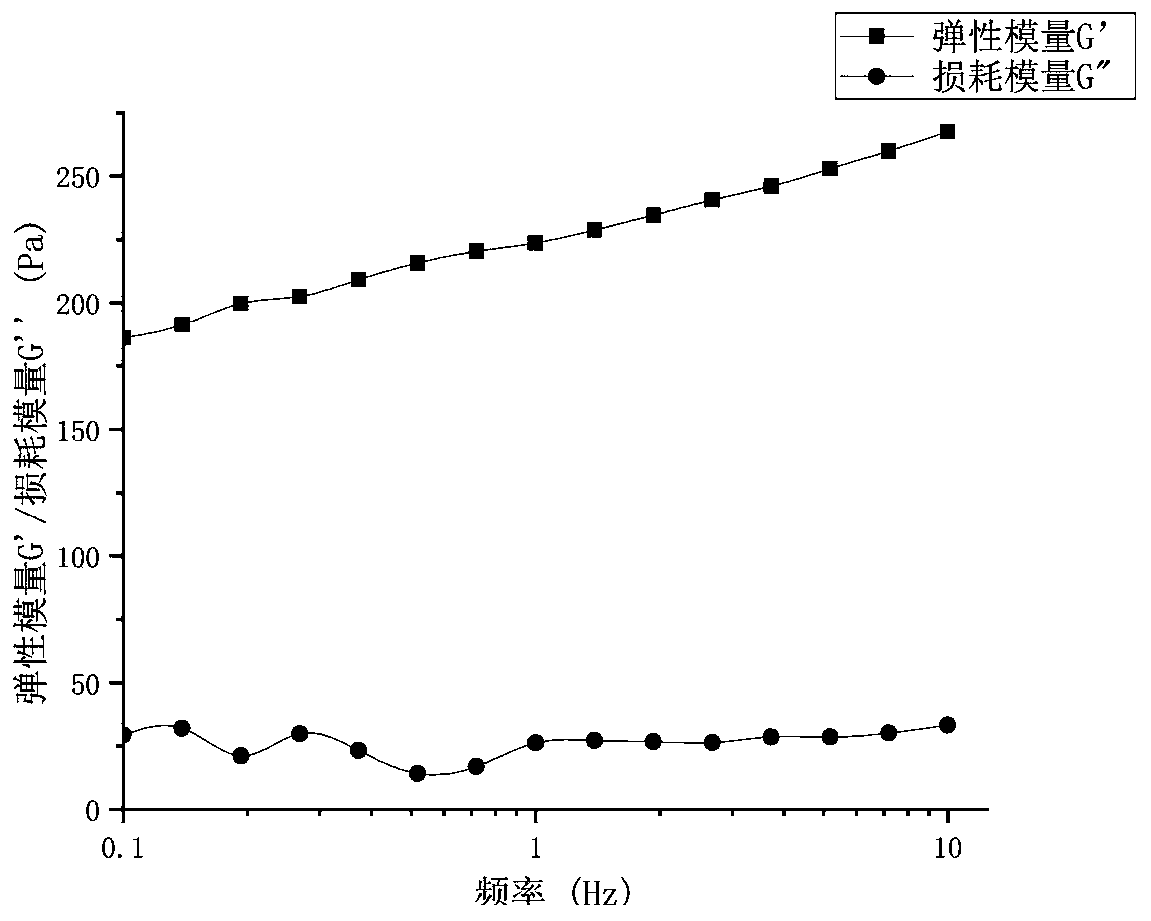

[0037] After the egg white protein was heat-treated in a water bath at 90°C for 40 minutes, it was immediately ice-bathed, cooled and left to stand at 4°C for 24 hours to form an opaque gel. The gel was crushed, and the protein concentration was 1.8% with deionized water. After pre-homogenization at 11000 rpm for 3 min, ultrasonic crushing was performed at 400 w for 30 min to obtain a microgel dispersion.

[...

Embodiment 3

[0040] Step 1: Egg white pretreatment: Wash the fresh eggs with clean water, use an egg white separator to separate the egg white from the egg yolk, and remove the umbilical cord in the egg white. Then the egg white was stirred at a medium speed for 1 hour and then filtered through a 20-mesh sieve to obtain an egg white solution. The egg white protein solution was sonicated at an ultrasonic power of 300w for 15 minutes and then diluted with deionized water with a pH of 8.8 to a protein concentration of 5%. Whisk slowly for 2.5 hours with a magnetic stirrer. Stand at 4°C for 24h.

[0041] After the egg white protein was heat-treated in a water bath at 90°C for 40 minutes, it was immediately ice-bathed, cooled and left to stand at 4°C for 24 hours to form an opaque gel. The gel was mashed, and the protein concentration was 1.8% with deionized water. After pre-homogenization at 10000 rpm for 3 min, ultrasonic crushing was performed at 400 w for 30 min to obtain a microgel dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com