Cow leather fatting agent and fatting process

A technology of fatliquor and cowhide, which is applied in the directions of leather impregnation, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., which can solve the problem of insufficient adhesion between oil and leather , Grease shedding and other problems, to achieve the effect of improving the adhesion and bonding effect, prolonging the service life and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

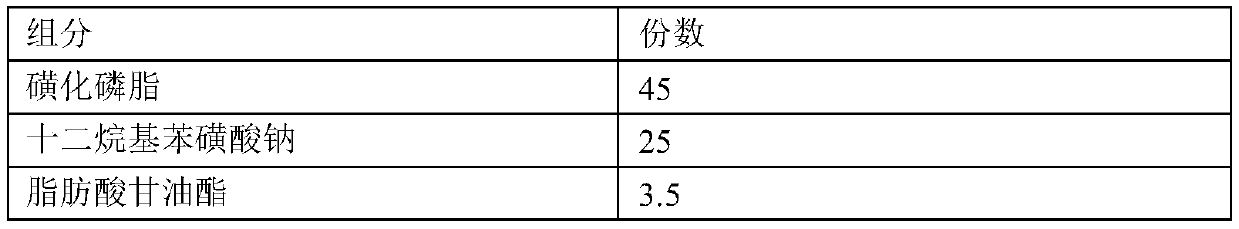

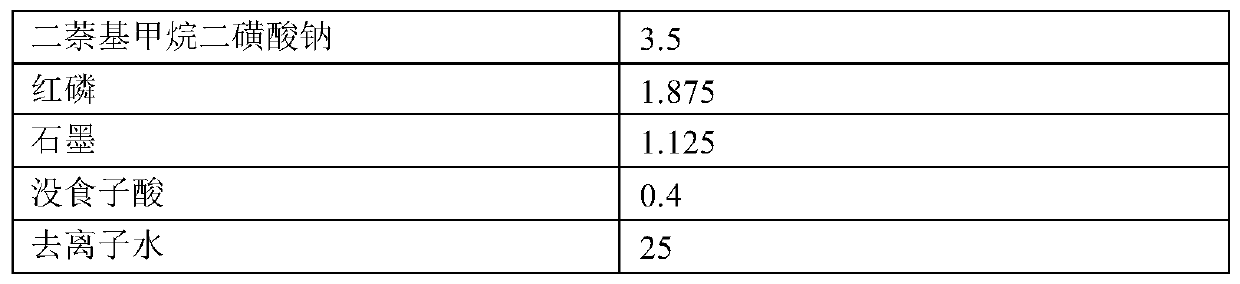

[0035] Embodiment 1 is a kind of bovine leather fatliquoring agent and fatliquoring process disclosed by the present invention, and the fatliquoring agent comprises the following components by weight:

[0036]

[0037]

[0038] The preparation method of sulfonated phospholipid is:

[0039] A1. Chlorination of phospholipids: heat the phospholipids to 65°C, then pass in chlorine gas for chlorination reaction, and control the density of chlorinated phospholipids to 1.05g / mL;

[0040] A2. Sulfonation of chlorinated phospholipids: quantitatively send chlorinated phospholipids to the glass tube sulfonation reactor through a metering pump, and set the jacket circulating water temperature to 70°C; SO 3 The dry gas is passed into the sulfonation reactor through the pipeline, and the chlorinated phospholipid and SO 3 The gas undergoes a sulfonation reaction to obtain a sulfonated phospholipid pre-product;

[0041] A3. Neutralization: Use dilute NaOH solution to neutralize the pH...

Embodiment 2

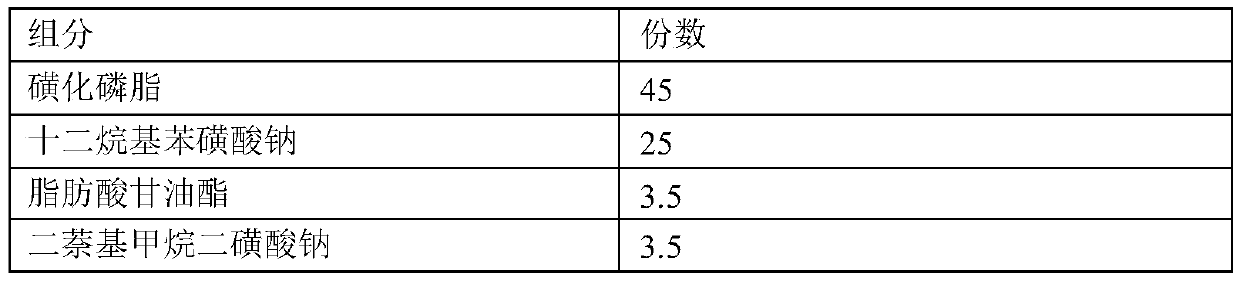

[0047] Embodiment 2 is a kind of bovine leather fatliquoring agent and fatliquoring process disclosed by the present invention, and the fatliquoring agent comprises the following components by weight:

[0048] components number of copies Sulfonated phospholipids 30 Sodium dodecyl benzene sulfonate 15 fatty acid glycerides 2 Sodium dinaphthylmethane disulfonate 1.5 Red phosphorus 0.71 graphite 0.29 gallic acid 0.3 Deionized water 10

[0049] The preparation method of sulfonated phospholipid is with embodiment 1;

[0050] The specific steps of the fatliquoring process are the same as in Example 1.

Embodiment 3

[0051] Embodiment 3 is a kind of bovine leather fatliquoring agent and fatliquoring process disclosed by the present invention, and the fatliquoring agent comprises the following components by weight:

[0052] components number of copies Sulfonated phospholipids 60 Sodium dodecyl benzene sulfonate 35 fatty acid glycerides 5 Sodium dinaphthylmethane disulfonate 5.5 Red phosphorus 3.57 graphite 1.43 gallic acid 0.5 Deionized water 40

[0053] The preparation method of sulfonated phospholipid is with embodiment 1;

[0054] The specific steps of the fatliquoring process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com