Locking tool for tire dynamic balance test and tire dynamic balance test system

A technology of tires and tools, which is applied in the fields of locking tools for tire dynamic balance detection and tire dynamic balance detection systems, can solve problems such as low efficiency, affecting production efficiency, and easy wear and tear, and achieves saving time and cost, good fixing effect, speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

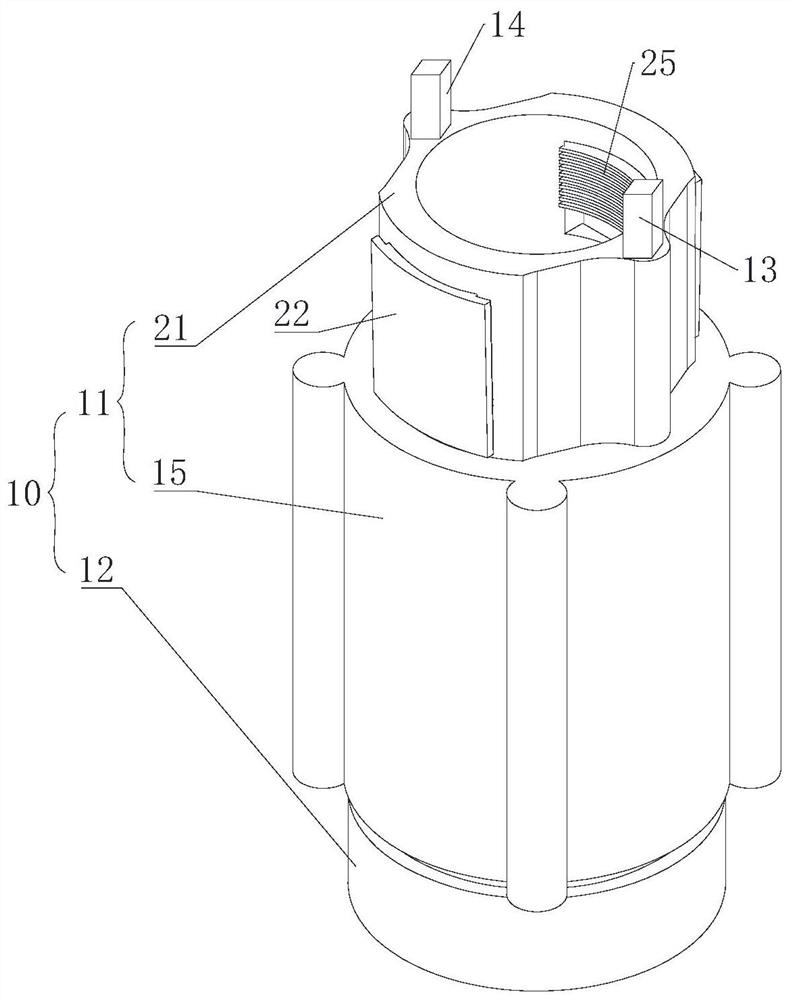

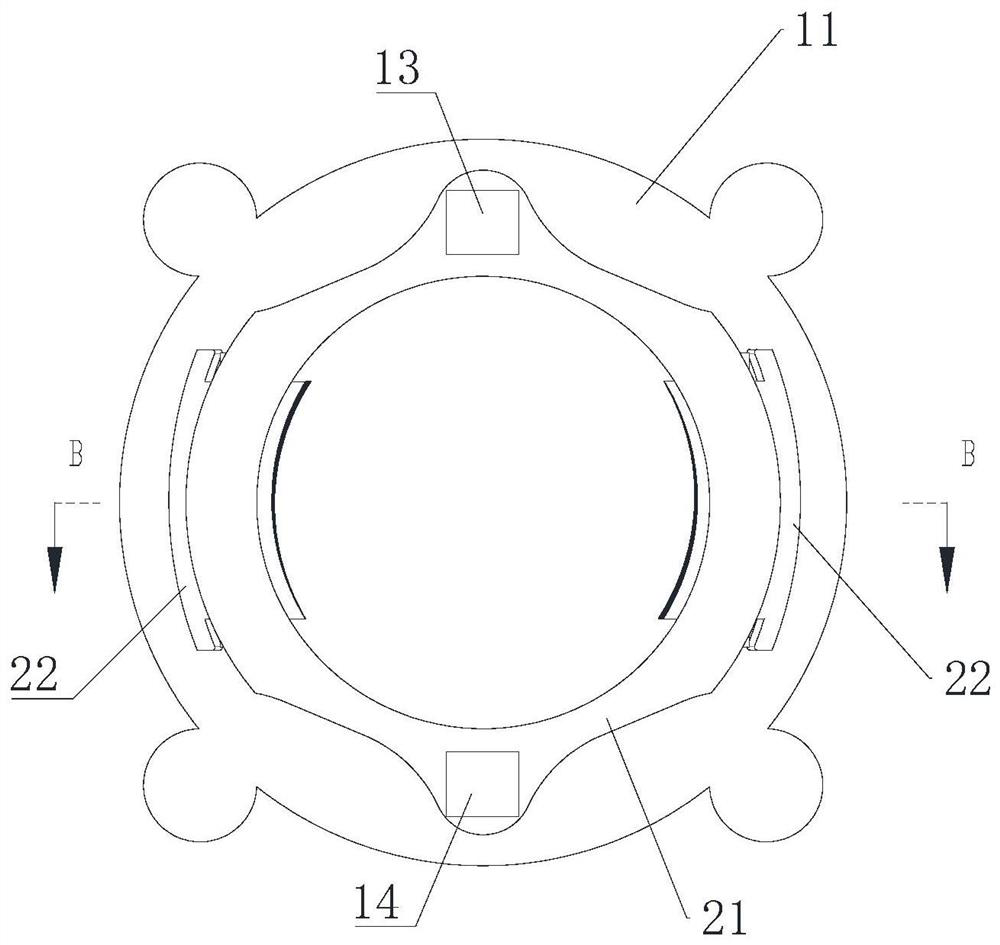

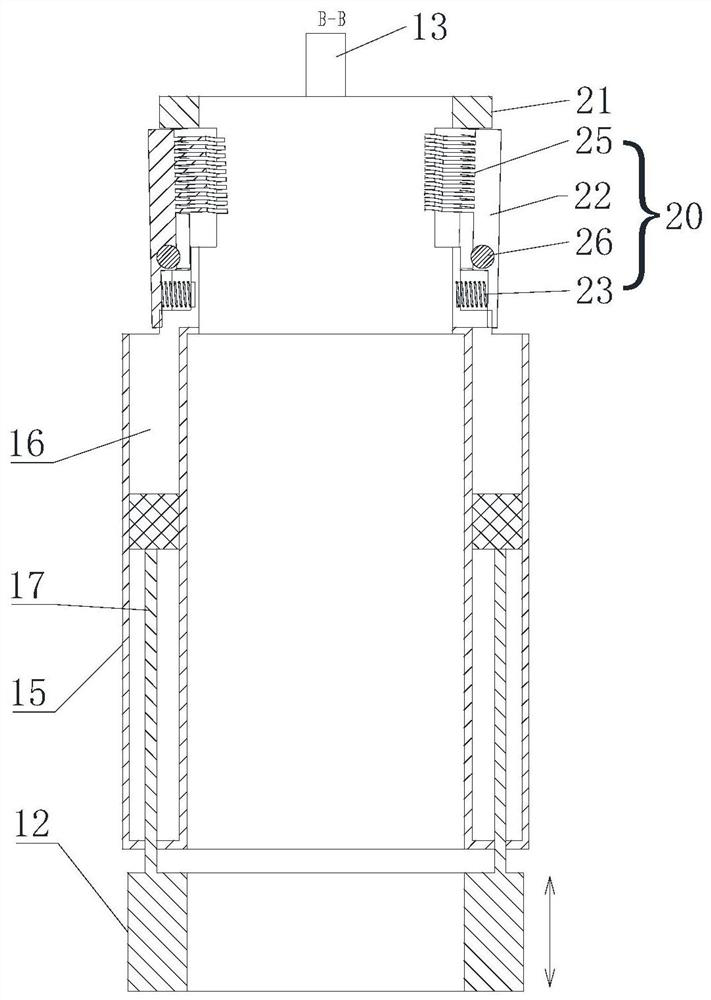

[0034] In this embodiment, through the combination of the telescopic mechanism 10 and the clamping device 20, the locking tool is avoided due to frequent screwing.

[0035] As shown in FIG. 2, in some embodiments, the body portion 11 includes a cylinder 15 and a sleeve 21, and the telescopic portion 12 is located in the cylinder

[0042] Wherein, the body portion 11 may be integrally formed, or may be composed of two parts of the cylinder cavity 16 body and the sleeve 21. exist

[0043] In other embodiments, the elastic member 23 can also be set in a variety of ways, for example: compression set on the clip 22

[0049] In a further embodiment, the stop structure is an inclined surface structure. That is to say, when the cylinder chamber 16 is in a pressurized state, the clip 22 moves toward the

[0050] In some embodiments, the side of the telescopic portion 12 facing the hub is provided with a protective pad. Protective pads are used in the telescopic part 12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com