Mini half-drought type paddy planter

A technology of semi-dry type and direct seeding machine, which is applied to the parts of planter, the machinery of interval-type quantitative seeding, and sowing, can solve the problems such as the improvement of agricultural production efficiency, the large workload of direct seeding machine and the low production efficiency that hamper the productivity of farmers. , to achieve high output, increase effective splitting, and good ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

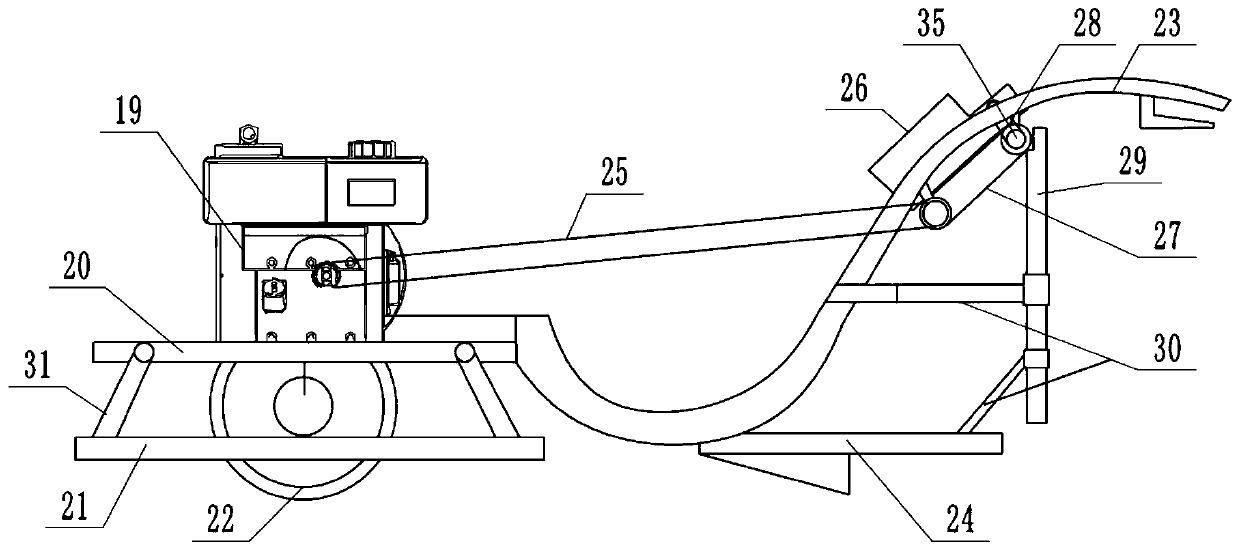

[0022] Such as Figure 1-2 Shown, a kind of miniature semi-dry type rice direct seeding machine has comprised several parts, is respectively power mechanism, sowing mechanism, field dividing mechanism 2424; Described power mechanism comprises motor 19, and motor 19 is provided with bottom and side two An output shaft, the bottom of the engine 19 is provided with a bracket 20, the bracket 20 is fixedly connected with balance plates 21 located at both sides of the engine 19, and the output shaft at the bottom of the engine 19 is also equipped with a moving forward wheel 22 The two sides of one end of the support 20 are fixedly connected with two handles 23 for operation, the field dividing mechanism 24 is fixedly connected to the bottom of the two handles 23, and the planting mechanism is fixedly installed at the bend of the handle 23 tops; On the output shaft at the side of the engine 19 is provided a first belt 25 connected to the next mechanism.

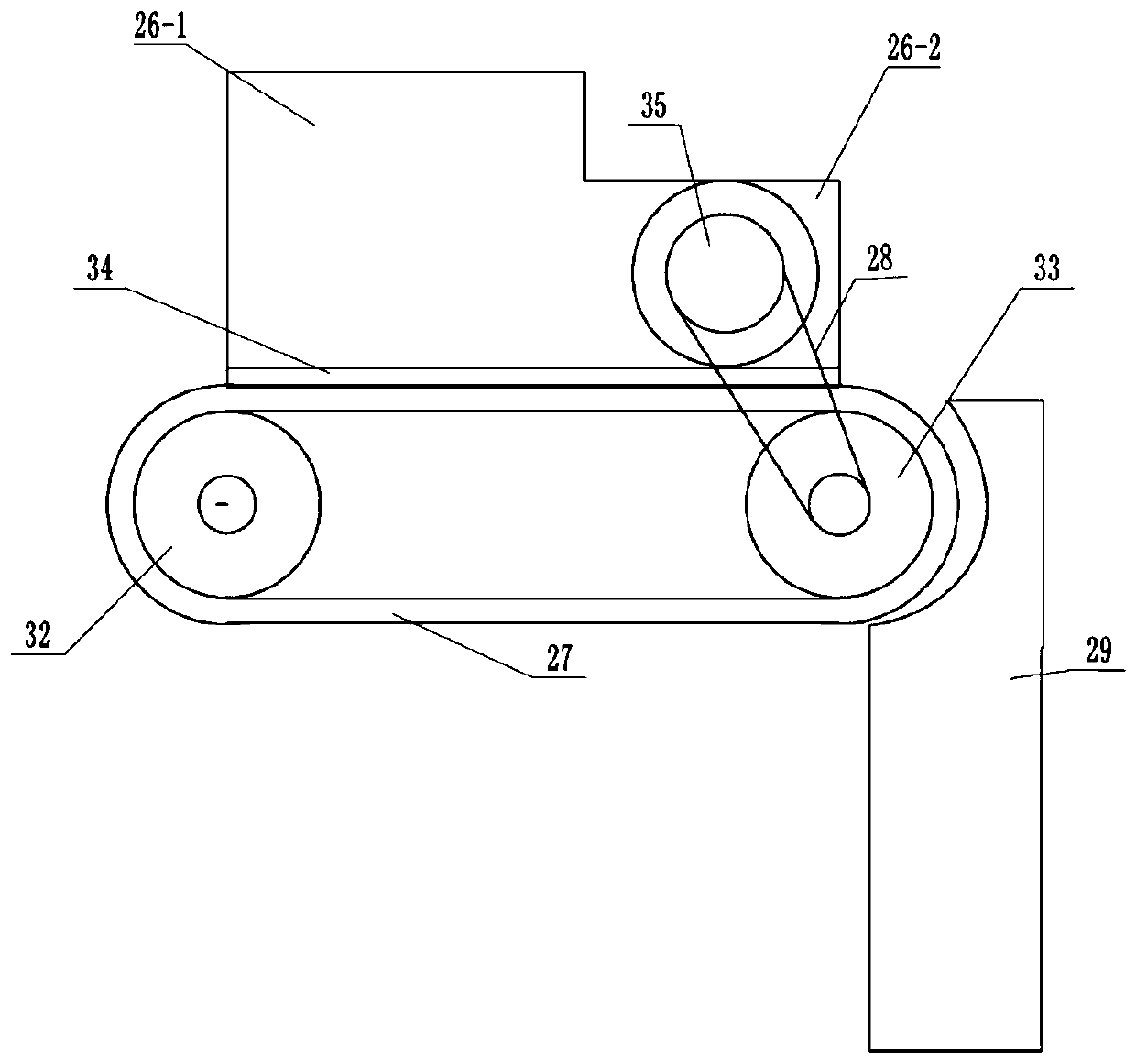

[0023] The planting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com