Sowing device

A seed and belt technology, applied in the field of planting devices, can solve the problems of inability to germinate and grow seeds, reduce land utilization, increase production costs, etc., and achieve the effects of increasing effective splitting, good ventilation, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

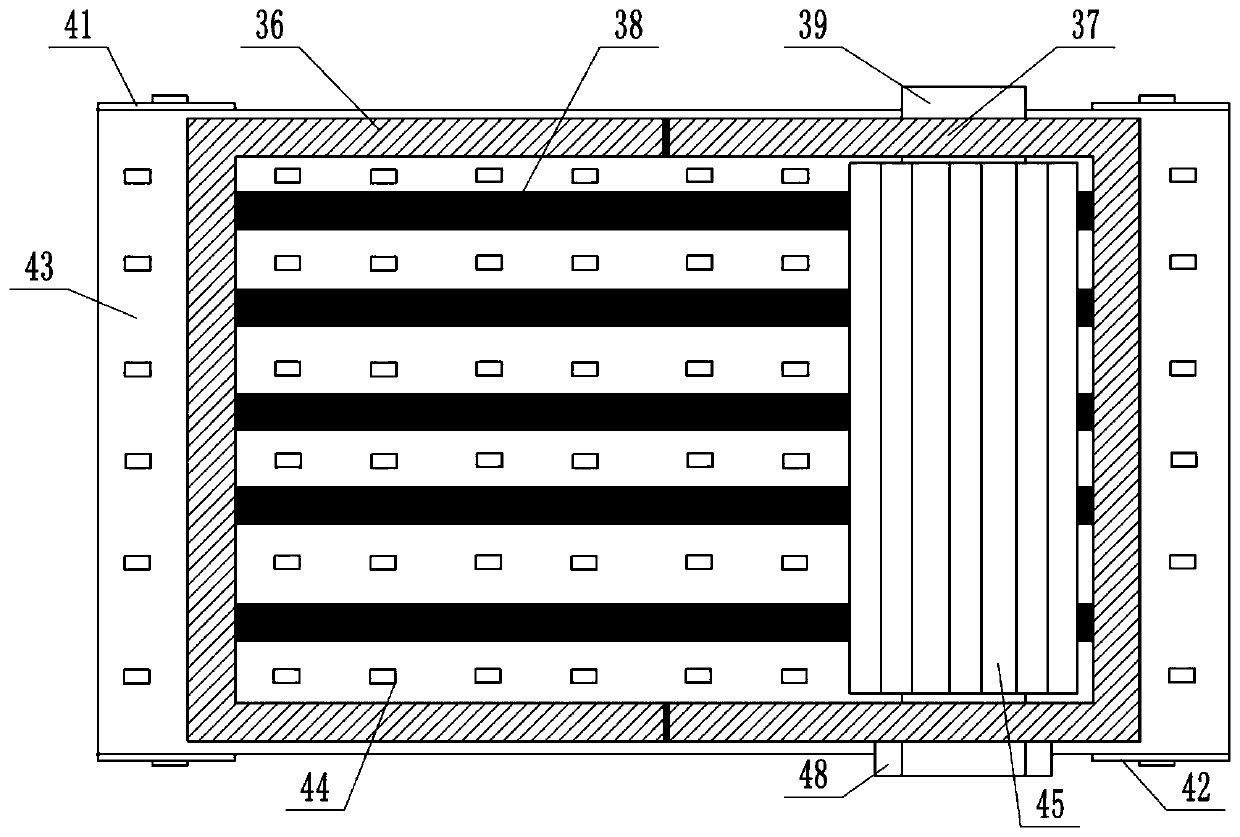

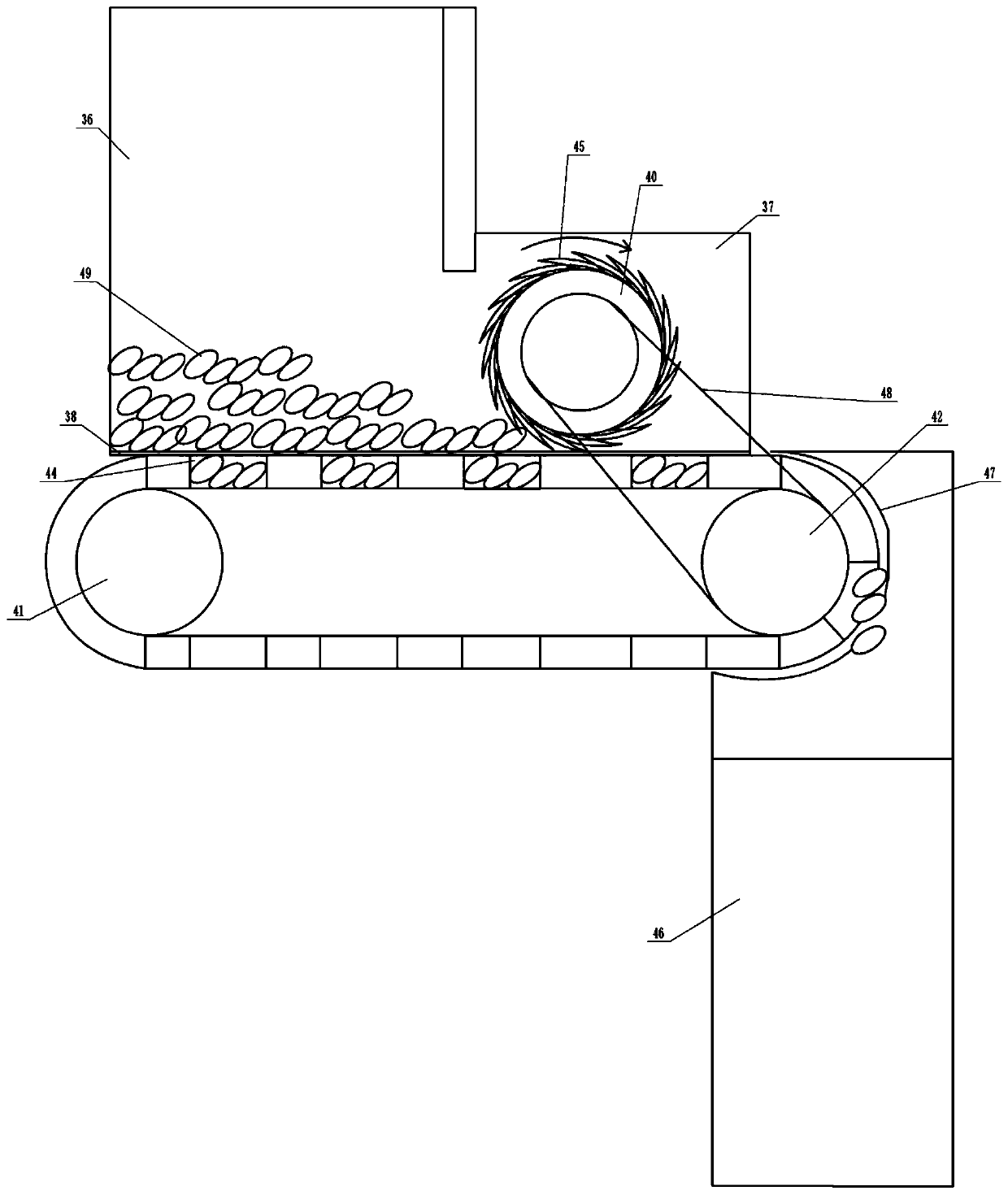

[0023] Such as Figure 1-2 As shown, a seeding device includes a seed box for holding seeds 49. The seed box is divided into a seed-holding area 36 and a seed-scanning area 37. The bottom of the seed-holding box has an opening 47. A number of spacers 38 are arranged at intervals along the length of the bottom of the seed box. A rotating shaft 39 is installed inside the scanning area 37. A rotating drum 40 for sweeping the seeds 49 is arranged on the rotating shaft 39. There are a driving wheel 41 and a driven wheel 42 for transmission. The driving wheel 41 and the driven wheel 42 are respectively located below the ends of the two ends of the seed box. The driving wheel 41 can be driven by an external power device. A first belt 43 for transporting seeds 49 is provided between 41 and the driven wheel 42. A first belt 43 that can drive the rotating shaft 39 to rotate is also installed on the driven wheel 42; the outer surface of the first belt 43 and the spacer 38 Connected, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com