Automatic solar panel cleaning device

A solar panel, automatic cleaning technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of complicated installation of guide rails, damage to photovoltaic panels, and reduce photovoltaic power generation efficiency, etc., to achieve fast and convenient installation. , highly efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

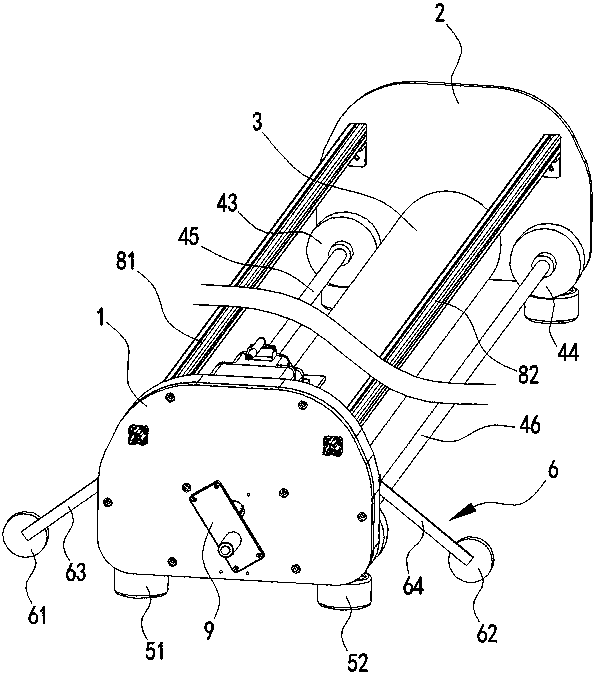

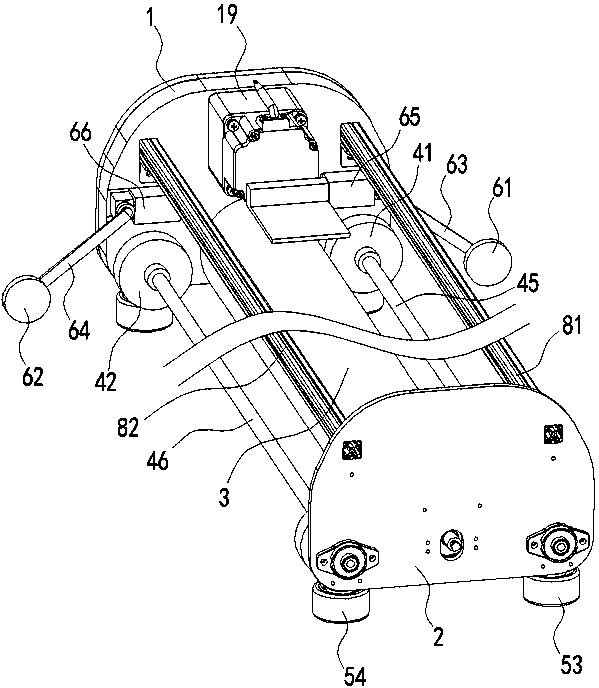

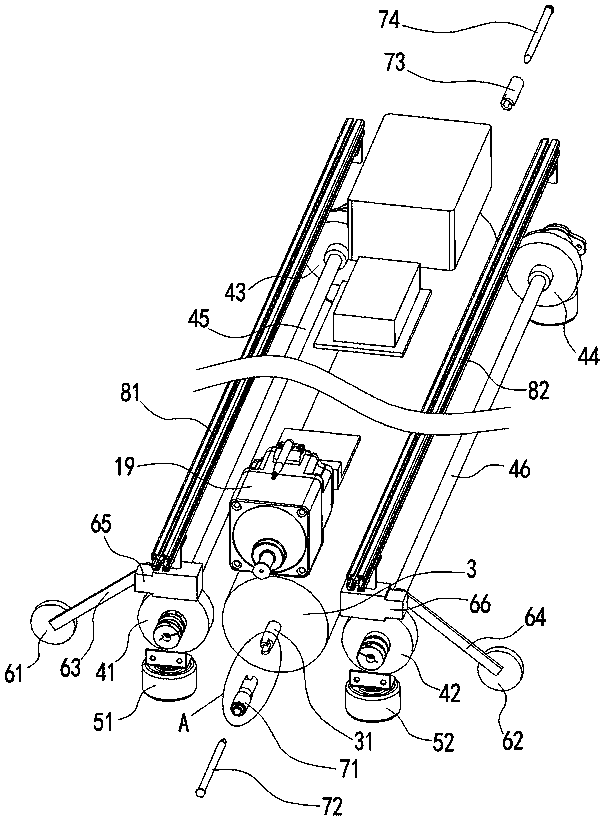

[0033] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine Figure 1-Figure 8 The accompanying drawings describe the present invention in further detail.

[0034] refer to figure 1 , figure 2 As shown, a kind of solar panel automatic cleaning device comprises roller brush shaft 31, roller brush 3 and front and rear mounting plates 1,2 fixed on the roller brush shaft 31, and the front and rear ends of roller brush shaft 31 rotate respectively It is arranged on the front and rear mounting plates 1 and 2, and the roller brush shaft 31 is driven by the driving device to rotate the linkage roller brush 3 to rotate between the front and rear mounting plates 1 and 2 for cleaning.

[0035] The front and rear mounting plates 1 and 2 are respectively fixed on the beam with adjustable spacing, and the front and rear mounting plates 1 and 2 are respectively locked on any position of the beam by screws so as to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com