Anti-toppling device of crawler-type mechanical inspection vehicle

A crawler-type, inspection vehicle technology, applied in the direction of tracked vehicles, motor vehicles, mechanical equipment, etc., can solve the problems of unable to adjust the extension angle, unusable, limited vehicle support strength, etc., to achieve good fixing effect and stable vacuum adsorption , adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

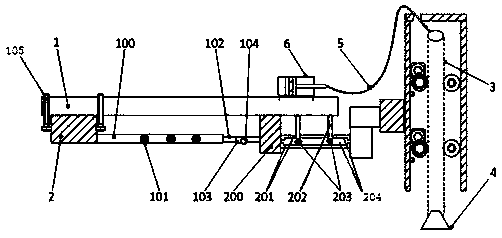

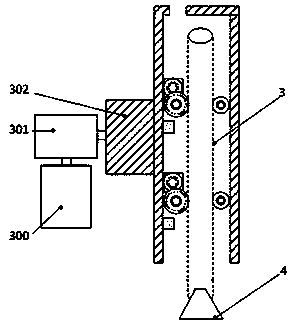

[0032] see Figure 1-Figure 5 , the present invention is mainly to solve the problem that the crawler-type mechanical inspection vehicle is easy to dump in the prior art, and the anti-dumping device in the prior art cannot be fixed at multiple angles. The invention discloses a crawler-type mechanical inspection vehicle. The dumping device includes a first connecting part 2 installed on the lower surface of the crawler mechanical vehicle chassis 1, the left and right sides of the first connecting part 2 are connected with outer metal rods 100, and the end of the outer metal rod 100 far away from the first connecting part 2 is connected with a horizontal The steering gear 300 and the execution end of the horizontal steering gear 300 are connected to the vertical steering gear 301 , and the execution end of the vertical steering gear 301 is connected to the vertical driving device through the third connection part 302 .

[0033] The vertical driving device is set on both sides of...

Embodiment approach 2

[0038] This embodiment is a further optimization of Embodiment 1. The specific optimization plan is: the inner metal rod 102 is nested and slidably connected to the outer metal rod 100, and a fastening mechanism that can limit the inner metal rod 102 is also provided on it. device, the inner metal rod 102 is connected to the horizontal steering gear 300 at one end away from the outer metal rod 100 .

[0039] The fastening device includes an elastic steel sheet 103 wrapped on the outer tube wall of the inner metal rod 102 and a metal hemisphere 104 arranged on the steel sheet 103. Holes 101 are spaced apart on the tube wall of the outer metal rod 100, and the metal hemisphere The body 104 can penetrate the hole 101. When the inner metal rod 102 stretched out, the metal hemisphere 104 on the steel sheet 103 was stuck by the hole 101 on the outer metal rod 100, and the inner metal rod 102 was fixed at this point. When the rod 102 is retracted inwardly, the metal hemisphere 104 on...

Embodiment approach 3

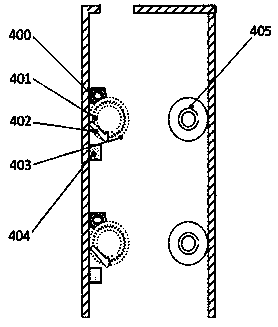

[0044] This embodiment is a further optimization of Embodiment 2, and the specific optimization scheme is as follows: figure 1 and image 3 As shown, a ratchet locking device is also provided on the power gear 403, and the ratchet locking device includes a ratchet 401 that is integrated with the power gear 403, a ratchet 402 that is in contact with the ratchet 401, and an electromagnet 404. The electromagnet 404 is located at On one side of the ratchet 402, its electrification can absorb the ratchet 402, so that the ratchet 402 is separated from the ratchet 401 to release the locking of the power gear 403;

[0045] In this embodiment, the ratchet 401 and the ratchet 402 are used together, and the electromagnet 404 is energized to adsorb the ratchet 402, so that the ratchet 402 is separated from the ratchet 401 to release the locking of the power gear 403. After locking, the vertical hollow support The tube will no longer move up and down for easy fixation.

[0046] Other ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com