Thin sheet material splicing device adaptive to different widths

A technology adaptable to different splicing devices, applied in the direction of thin material processing, application, winding strips, etc., can solve the problems of increasing investment and cost, splicing requirements of difficult sheet materials, and jamming of downstream equipment, etc., to simplify process steps and Equipment structure, reliable technical support, and the effect of ensuring tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

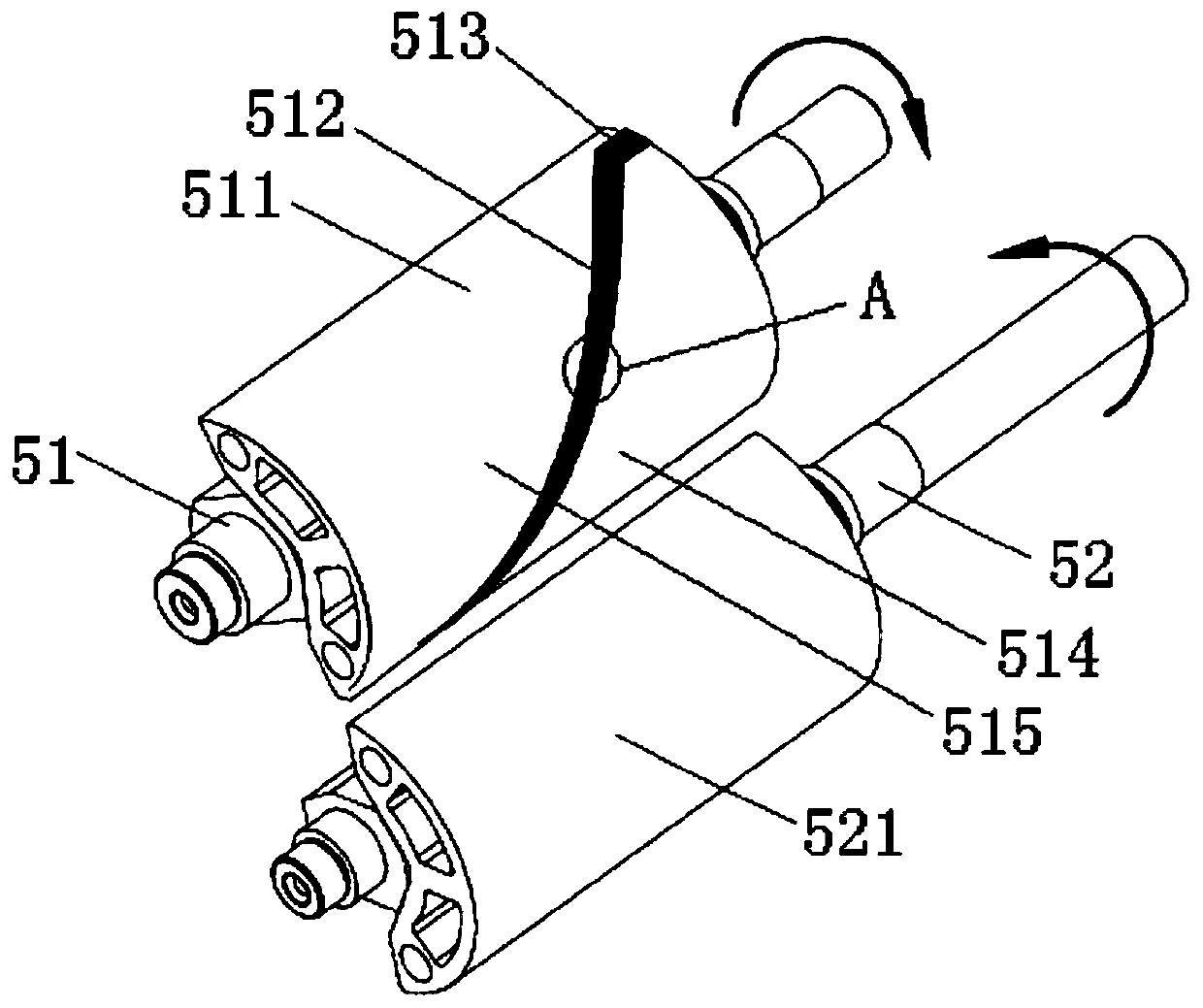

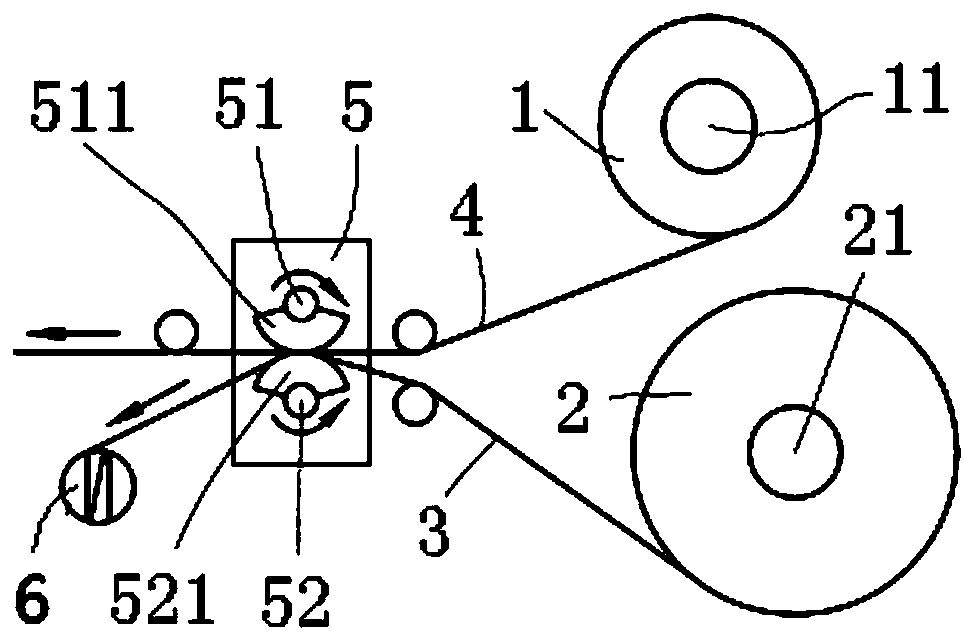

[0035] The pressure-adjustable sheet material splicing mechanism provided by the present invention includes first and second rollers mated with each other, and is characterized in that: an arc-shaped protrusion 512 is arranged on the roller surface 511 of the first roller, and the second roller The roller is set as a flat roller 521; the roller surfaces 511 and 521 of the first and second rollers are suspended on the mounting base 5; the second roller is connected with the lifting mechanism;

[0036] The arc-shaped protrusion 512 is a helical protrusion, obviously, it can also be a bent wavy line protrusion, or a continuous and smooth transition curve protrusion;

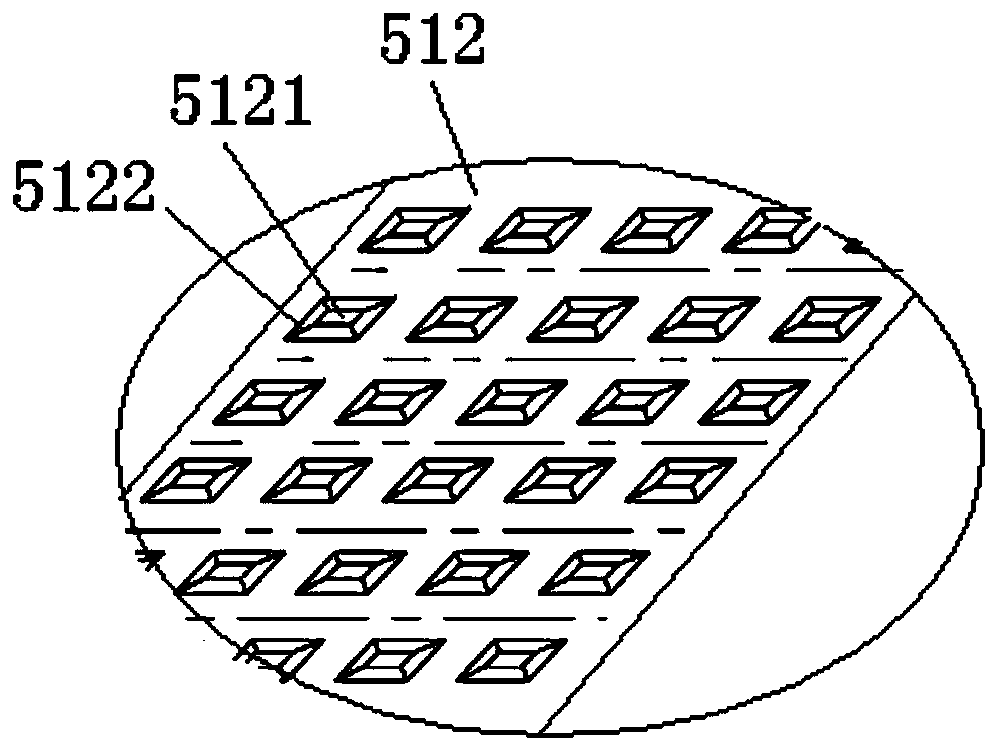

[0037] The surface of the arc-shaped protrusion 512 is provided with a number of independent concave-convex teeth at intervals, and the several independent concave-convex teeth are all quadrilateral teeth wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com