Q390D steel plate and production method thereof

A steel plate and stage technology, applied in the field of Q390D steel plate and its production, can solve the problems of easy cracks in the slab, poor surface quality of the steel plate, high alloy cost, etc., and achieve good surface quality, low cost, and good matching between strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

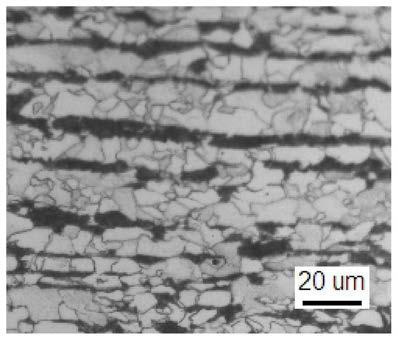

[0028] The molten steel undergoes RH treatment. The time required for the vacuum to be below 122 Pa during the treatment is 17 minutes, the frequency of electromagnetic stirring during slab continuous casting is 6.5 Hz, the current is 295 A, the reduction positions are 6, 7, and 8, and the reduction is 2.4mm, 2.4mm, 2.2mm, the thickness of the obtained continuous casting billet is 250mm. When the continuous casting billet is heated, a walking heating furnace is used. The continuous casting billet discharge temperature is 1235°C, the total heating time is 280 minutes, and the heating time in the soaking section is 30 minutes. The chemical composition of the slab (weight percentage) is: C0.16%, Si 0.24%, Mn 0.6%, Ti 0.07, P 0.015%, S 0.004%, Als 0.02%, Ca 0.0011%, the balance is Fe and unavoidable 的impurities. Rolled into a steel plate with a thickness of 14mm, the detailed rolling and cooling process is shown in Table 1, the mechanical properties of the obtained steel plate are ...

Embodiment 2

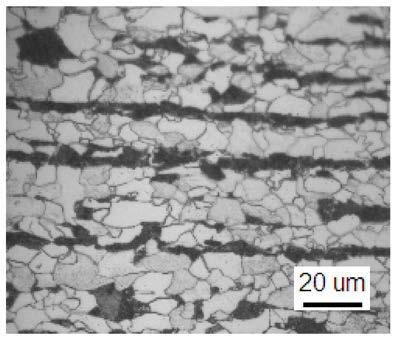

[0034] The molten steel undergoes RH treatment. The time required for the vacuum to be below 122 Pa during the treatment is 18 minutes, the frequency of electromagnetic stirring during slab continuous casting is 6.5 Hz, the current is 295 A, the reduction positions are 6, 7, and 8, and the reduction is 2.4mm, 2.4mm, 2.2mm, the thickness of the continuous casting billet is 250mm. The continuous casting billet is heated by a walking-type heating furnace, the furnace temperature is 1215°C, the total heating time is 220 minutes, and the heating time in the soaking section is 33 minutes. The chemical composition of the slab (weight percentage) is: C 0.18%, Si 0.34%, Mn 0.5%, Ti 0.06%, P 0.014%, S 0.003%, Als 0.035%, Ca 0.0026%, the balance is Fe and non-volatile Impurities to avoid. Rolled into a steel plate with a thickness of 21mm, the detailed rolling and cooling process is shown in Table 3, the mechanical properties of the obtained steel plate are shown in Table 4, and the meta...

Embodiment 3

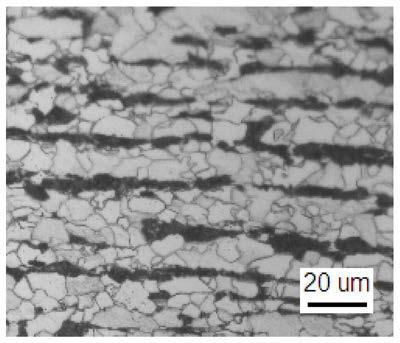

[0040] The molten steel undergoes RH treatment. The time required for the vacuum to be below 122 Pa during the treatment is 18 minutes, the frequency of electromagnetic stirring during slab continuous casting is 6.5 Hz, the current is 295 A, the reduction positions are 6, 7, and 8, and the reduction is 2.4mm, 2.4mm, 2.2mm, the thickness of continuous casting billet is 250mm. The continuous casting slab is heated by a walking-type heating furnace, the furnace temperature is 1228℃, the total heating time is 245 minutes, and the heating time in the soaking section is 35 minutes. The chemical composition (weight percentage) of the slab is: C 0.17%, Si 0.31%, Mn 0.56%, Ti 0.063%, P 0.013%, S 0.002%, Als 0.033%, Ca 0.0022%, and the balance is Fe and Inevitable impurities. Rolled into a steel plate with a thickness of 18mm, the detailed rolling and cooling process is shown in Table 5, and its mechanical properties are shown in Table 6, and the metallographic structure is as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com