Pulper for papermaking machinery

A technology of papermaking machinery and pulper, which is applied in the field of pulper for papermaking machinery, which can solve the problems of affecting paper quality and leaving pimples, and achieves the effect of convenient installation, disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

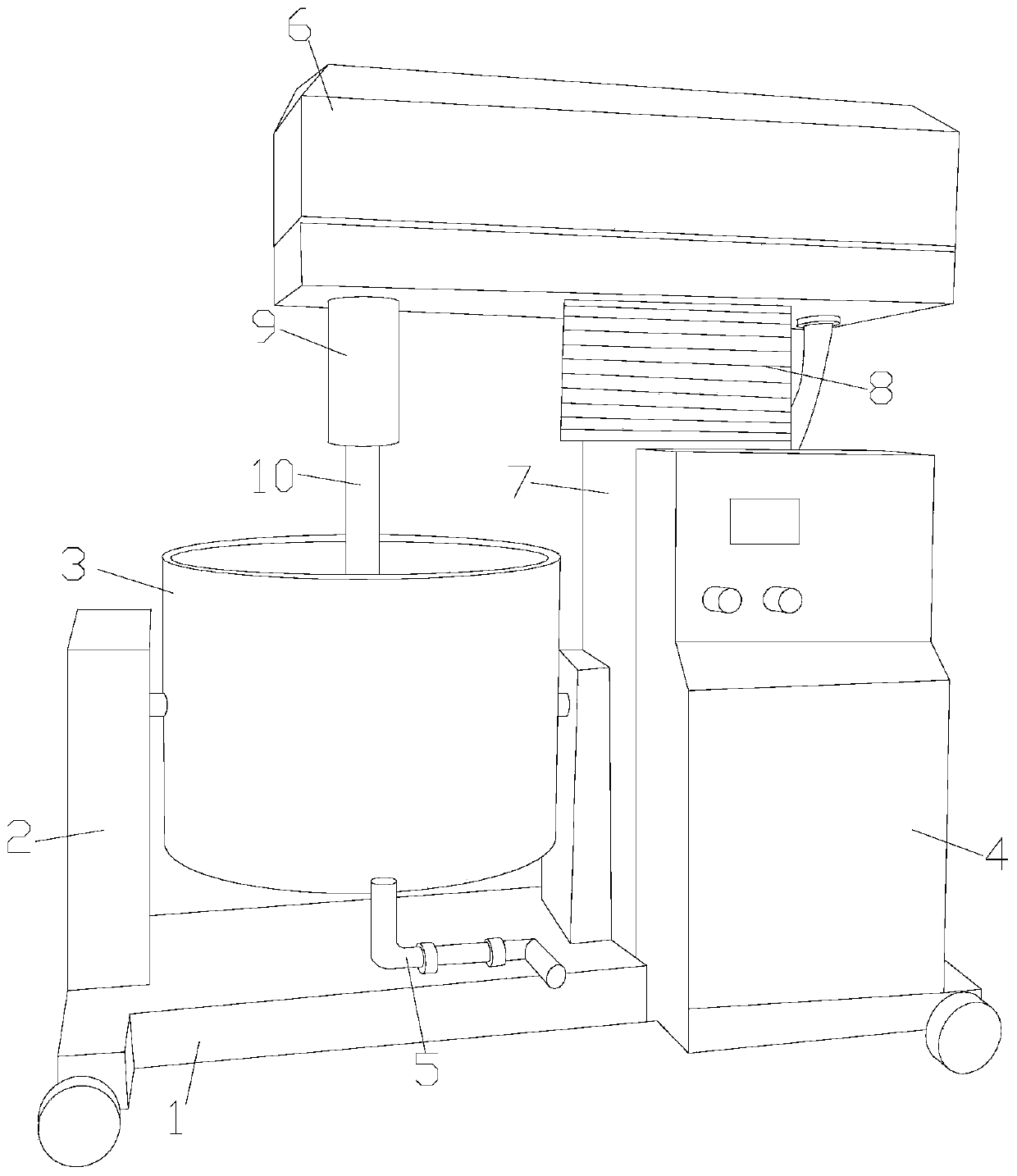

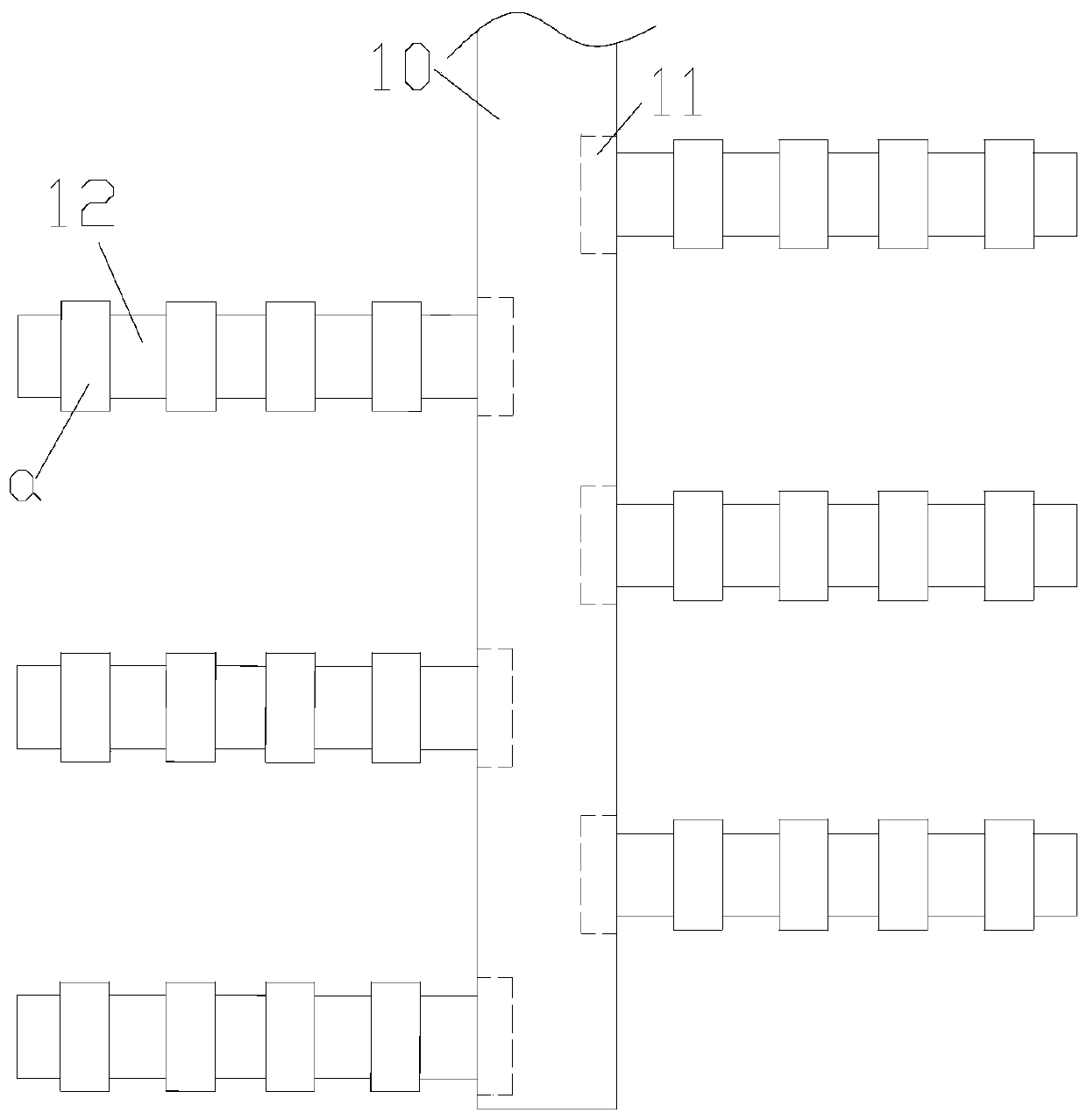

[0029] see Figure 1-Figure 4 As shown, the present invention provides a pulper technical solution for papermaking machinery: its structure includes a machine base 1, a stand 2, a tank body 3, a control box 4, a balance fixer 5, a driver 6, a lifting column 7, a telescopic anti- Dust cover 8, drive shaft 9, stirring shaft 10, a stand 2 is provided at the left end of the top of the base 1, a tank body 3 is movable in the middle of the stand 2, and a lift is installed on the right side of the tank body 3. The column 7 and the control box 4, the control box 4 is located in front of the lifting column 7, the top of the lifting column 7 is connected to the right side of the driver 6 and the position between the two is covered with a telescopic dust cover 8, so The left side of the bottom of the driver 6 is provided with a drive shaft 9, one end of the stirring shaft 10 is connected to the drive shaft 9, and the other end extends into the inside of the tank body 3, and a group of th...

Embodiment 2

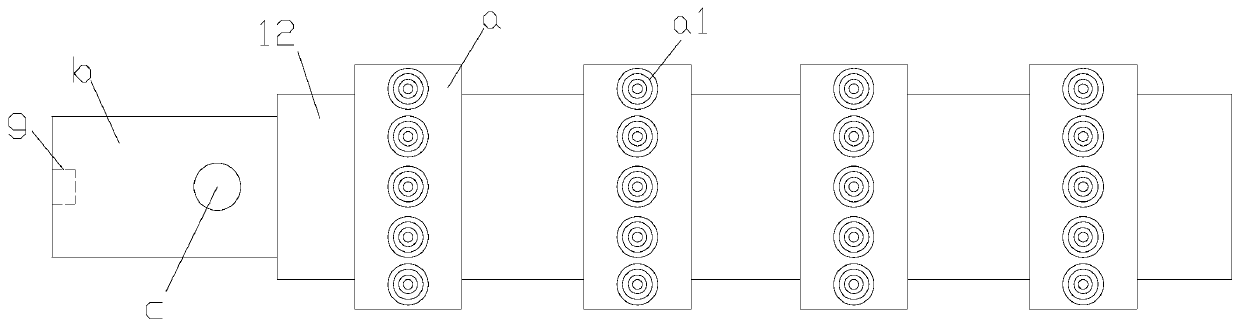

[0032] Such as Figure 5 with Image 6 As shown, on the basis of Embodiment 1, the tightener 11 is also composed of a clamping groove e1, a rotary cutout e2, and a tightening groove e3. Symmetrical rotary cutout e2, the rotary cutout e2 is connected with the tightening groove e3, the clamping groove e1 is equipped with a presser f inside, and the presser f is composed of a buckle rod f1, a top plate f2, and a spring f3, The presser f and the draw-in slot e1 are clearance fit, a spring f3 is arranged between the left side of the presser f and the bottom of the draw-in slot e1, and a buckle f1 is connected on the right side, and the buckle f1 of the presser f1 The size is smaller than the size of the fastening groove g, and the two are fastened and connected. The diameter of the clamping rod c is smaller than the diameter of the rotary cutout e2 and the tightening groove e3. Both the rotary cutout e2 and the tightening groove e3 For equal diameter.

[0033] The clamping shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com