Magnetic type safety guardrail

A safety guardrail and magnetic attraction technology, which is applied in road safety devices, roads, fire rescue, etc., can solve the problems of breaking the safety guardrail, endangering the driver's life safety, and vehicle damage, so as to improve the braking force and avoid traffic accidents , the effect of increasing the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

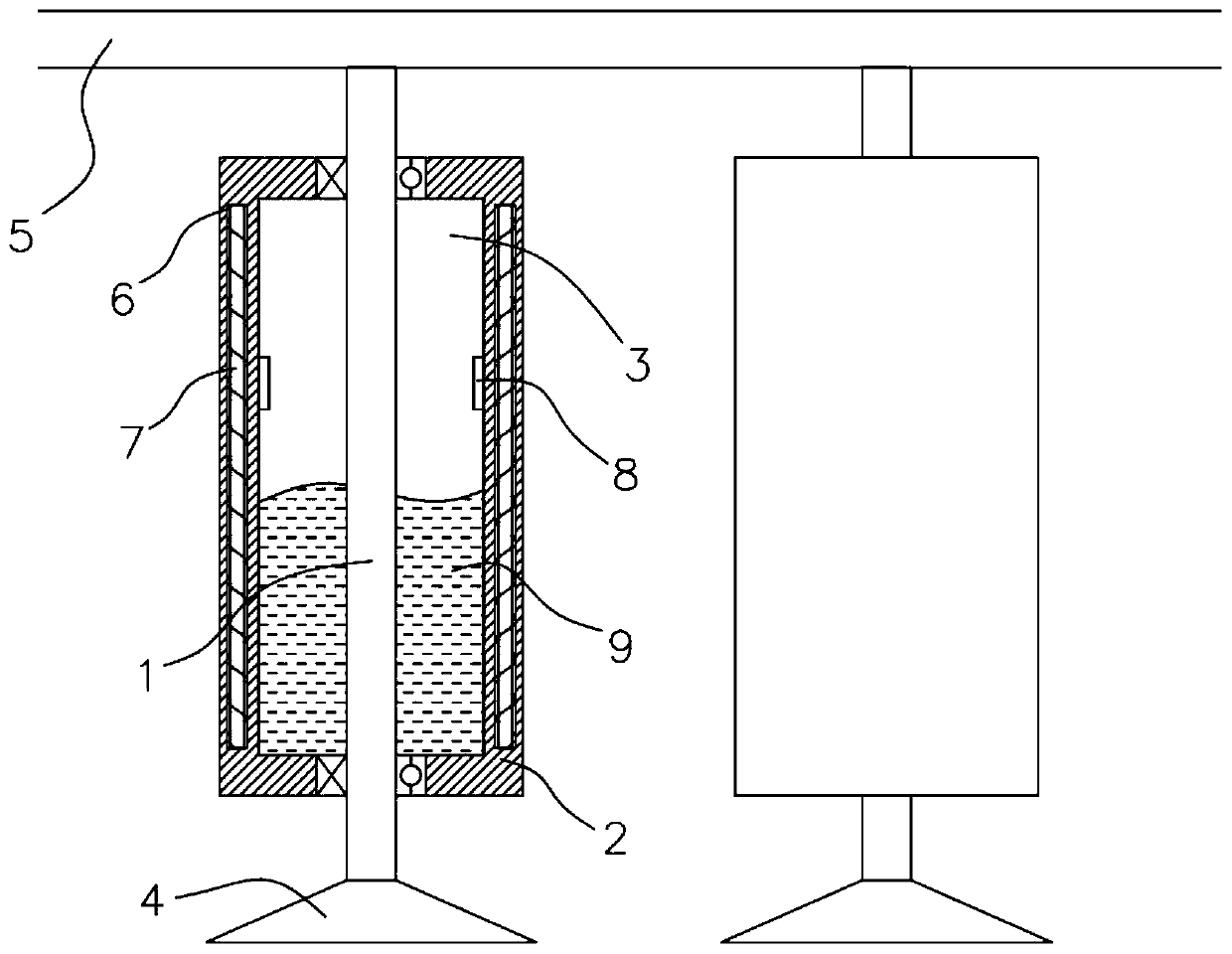

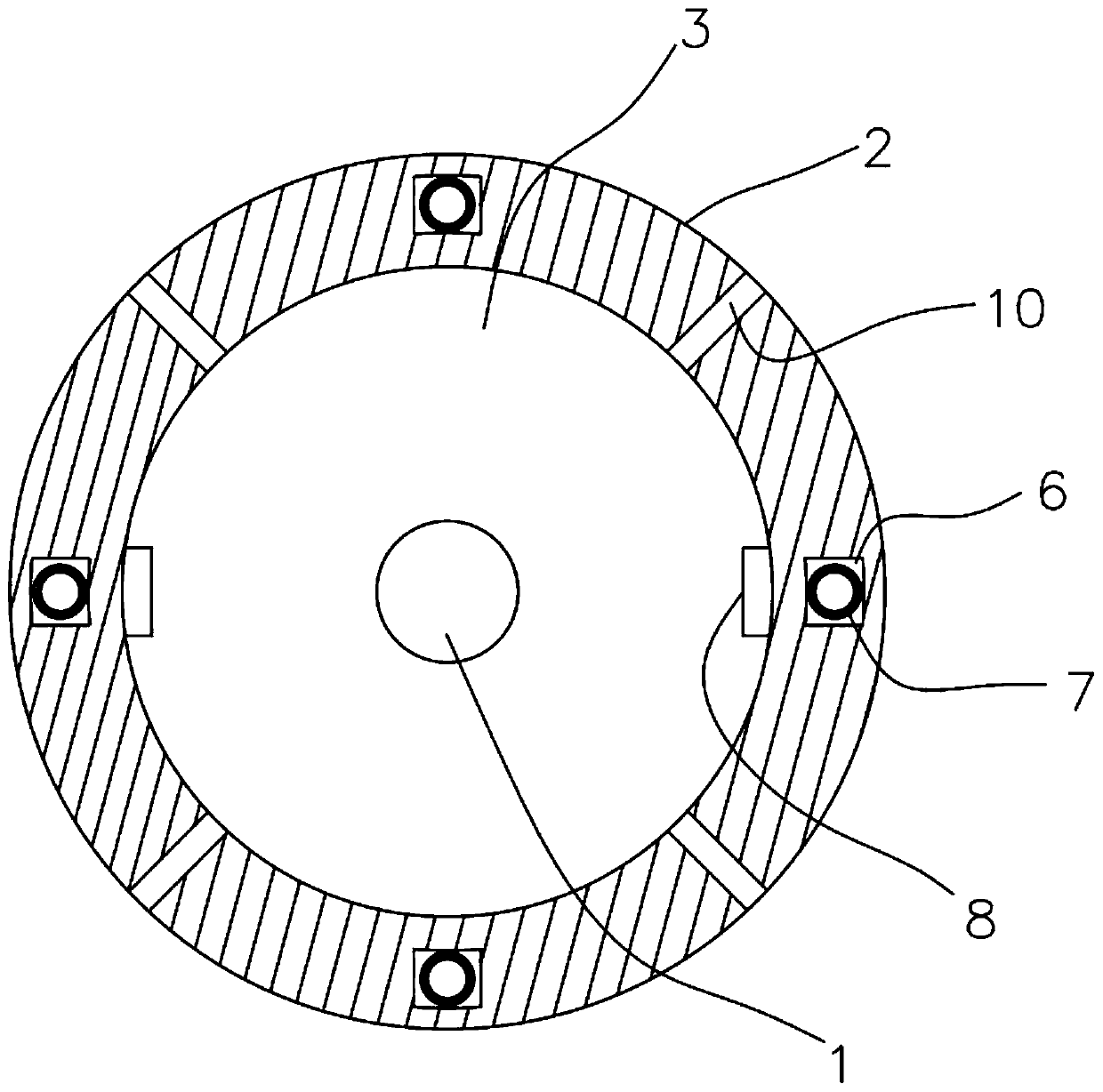

[0016] refer to Figure 1-2 , a magnetic attraction type safety guardrail, comprising a plurality of uprights 1, the lower ends of the plurality of uprights 1 are fixedly connected with a counterweight base 4 to lower the overall center of gravity, the upper ends of a plurality of uprights 1 are jointly fixedly connected with a connecting rod 5, and the upper ends of the uprights 1 pass through The sealed bearing is rotatably connected to the drum 2 to ensure the tightness. The drum 2 is provided with a hydraulic chamber 3 filled with a conductive liquid 9, and a liquid replenishment hole is provided at the inner top of the hydraulic chamber 3 to facilitate follow-up Timely replenishment of the conductive liquid 9, the inner wall of the hydraulic chamber 3 is symmetrically fixed with a conductive plate 8, and the inner circumference of the drum 2 is evenly provided with a plurality of installation cavities 6, and the inner walls of the installation cavities 6 are equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com