Non-contact turbine drive self-power-generating intelligent water distributor

A non-contact, self-generating technology, which is applied to engine components, machines/engines, mining fluids, etc., can solve the problems of time-consuming power supply and insufficient power supply, so as to improve production efficiency, save manpower and material costs, and reduce the difficulty of sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

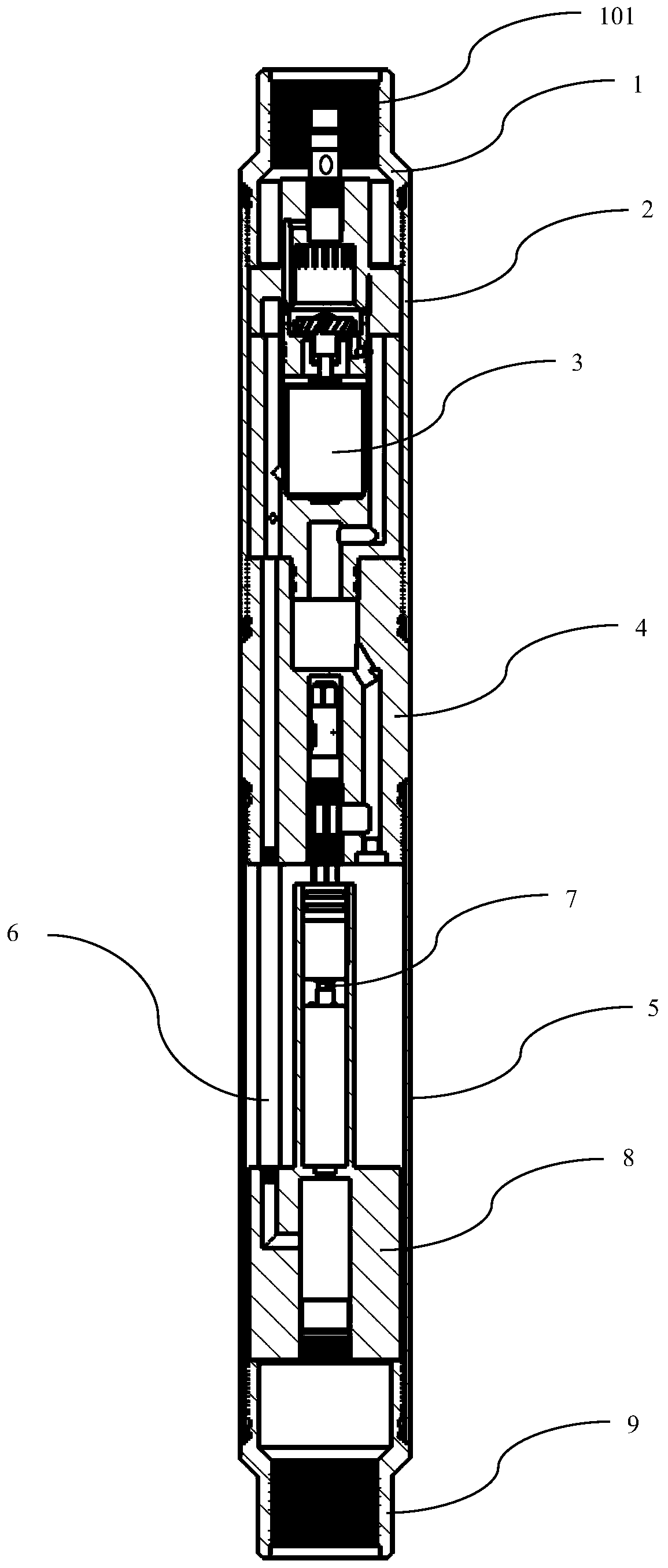

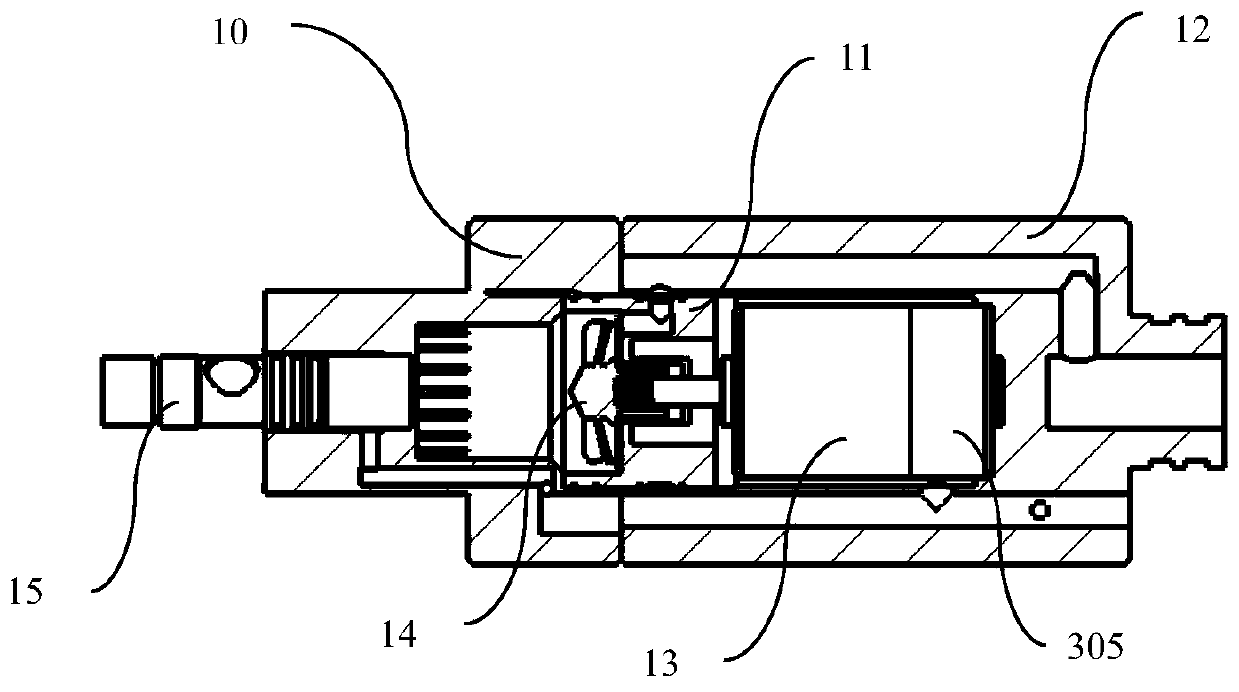

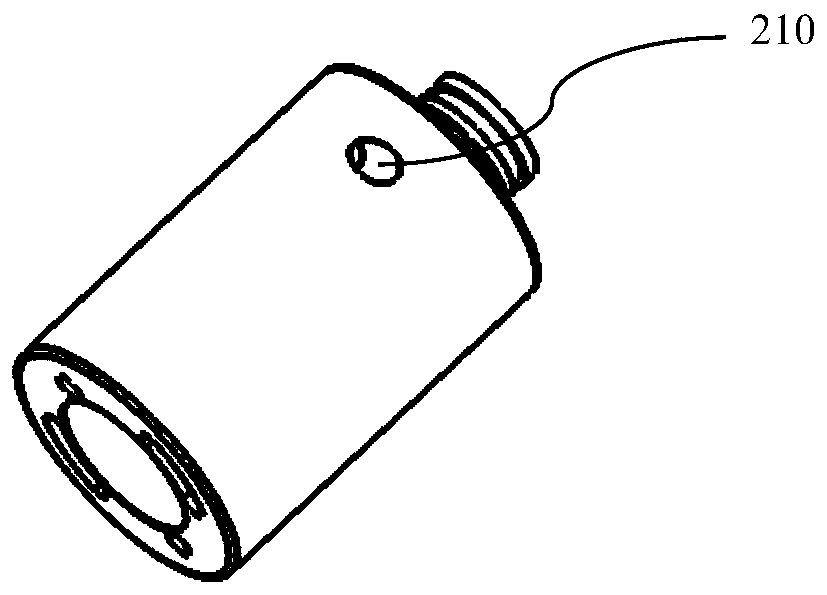

[0027] like Figure 1 to Figure 11 As shown, the components of the present invention include: upper joint 1, outer sleeve 2, generator assembly 3, main body 4, plug outer sleeve 5, wire conduit 6, magnetic coupling plug assembly 7, plug housing 8, lower The joint 9, wherein the upper joint 1 and the outer sleeve 2 are connected by an o-ring thread seal, the generator assembly 3 is inserted into the cavity formed by the upper joint 1 and the outer sleeve 2, and the upper joint 1 is used for positioning, The outer sleeve 2 and the main body 4 are connected by an o-ring thread seal, and the generator assembly 3 is connected by an o-ring sealing sleeve. It is connected with the outer sleeve 5 and the lower joint 9 of the plug by O-ring thread sealing, the inner conduit 6 is connected with the main body 4 and the plug shell 8 by an O-ring plug-in sleeve, and the magnetic coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com