A fully mechanized caving mining method with small and short walls horizontally segmented in steeply inclined thick coal seams

A mining method and technology for thick coal seams, which are used in surface mining, mining equipment, earthwork drilling, etc., can solve the problems of easy dumping and sliding of working face equipment, poor efficiency and safety, and high roadway excavation rate, and improve the degree of mining mechanization. , The effect of improving top coal discharge efficiency and coal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

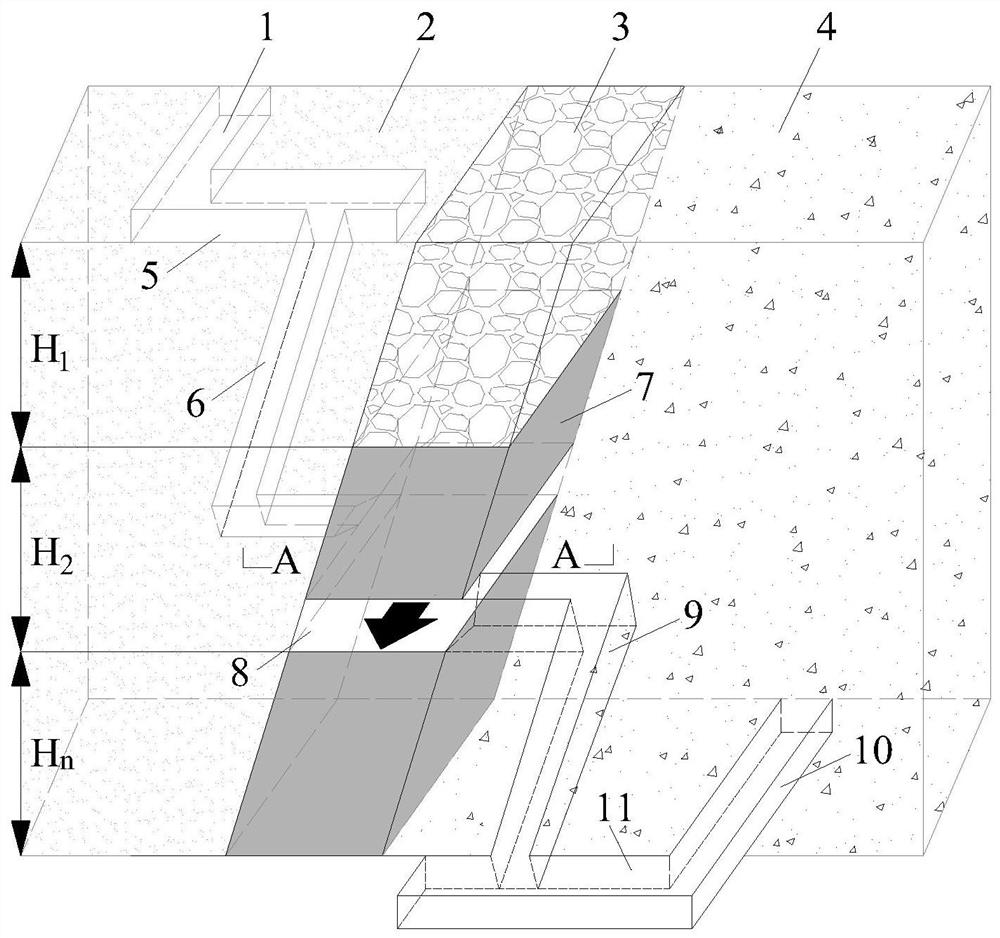

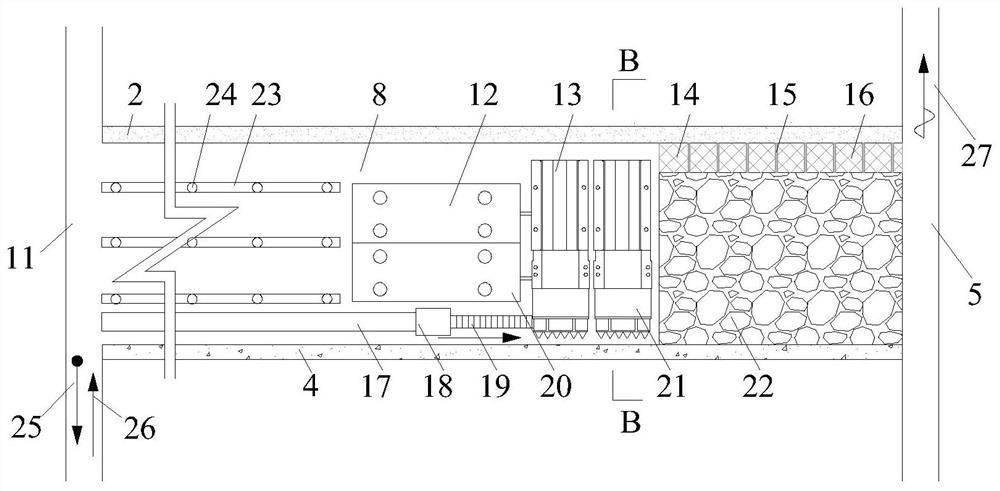

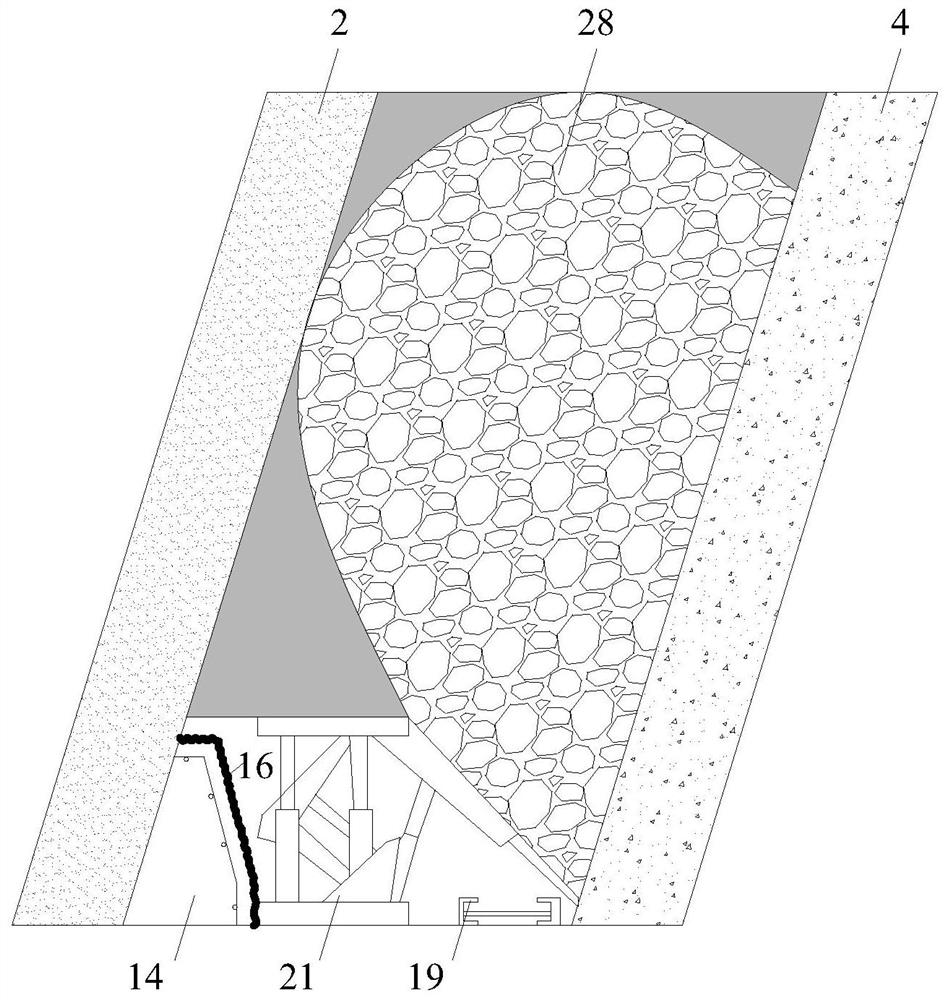

[0040]The method for fully mechanized caving mining of steeply inclined thick coal seams horizontally segmented with small short walls provided by the present invention is suitable for steeply inclined thick coal seams with a coal seam inclination greater than 55° and a coal seam thickness of 4m-10m. figure 1 , figure 2 and image 3 , the fully mechanized caving mining method specifically comprises the following steps:

[0041] 1. Arranging the roadway of the working face

[0042] 1. Coal seam segmentation

[0043] In one stage, the coal seam is divided into several horizontal sections along the dip, and the section height is about 10m, which can be adjusted according to different coal seam conditions.

[0044] In this specific embodiment, the height of adjacent sections is H 1 =H 2 =…=H n = 10m.

[0045] 2. Arranging the mining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com