Display panel and preparation method thereof

A technology for display panels and metal layers, applied in nonlinear optics, instruments, optics, etc., to achieve the effects of reducing reflectivity, reducing color deviation, and reducing differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

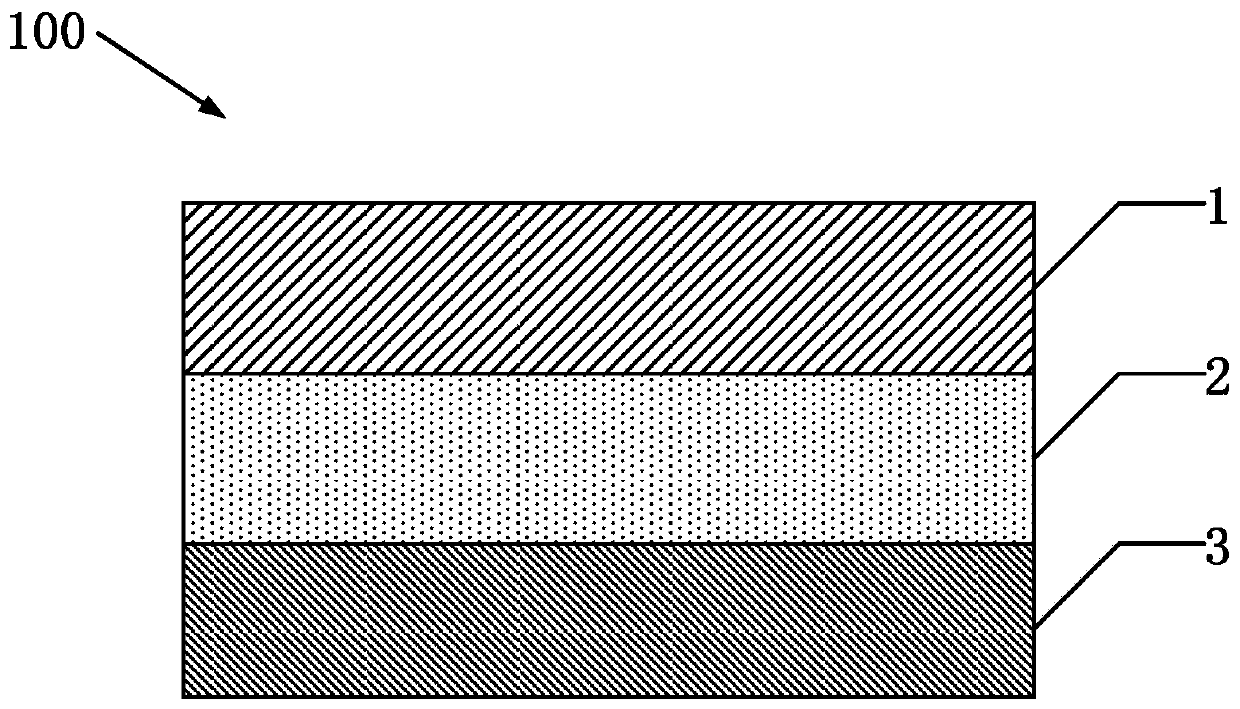

[0034] Such as figure 1 As shown, this embodiment provides a display panel 100 comprising: a metal layer 1 , a darkening layer 2 and a conductive layer 3 .

[0035] The material of the metal layer 1 includes: at least one of Cu, Mo, Ti, Al, Ni, Nb, Ta and Cr. Wherein the thickness of the metal layer is 200-700nm. Among them, 200 nm, 400 nm, and 600 nm are preferable. In this way, effects such as signal transmission can be achieved.

[0036] In fact, the display panel 100 includes a substrate and thin film transistors disposed on the substrate. The thin film transistor includes: an active layer, a gate insulating layer, a gate layer, an interlayer insulating layer, and a source-drain layer. The material of the gate layer and the source-drain layer is metal, so the metal layer 1 described in this embodiment is the gate layer and the source-drain layer in the thin film transistor.

[0037] The darkening layer 2 is disposed on one or both surfaces of the metal layer 1 , and i...

Embodiment 2

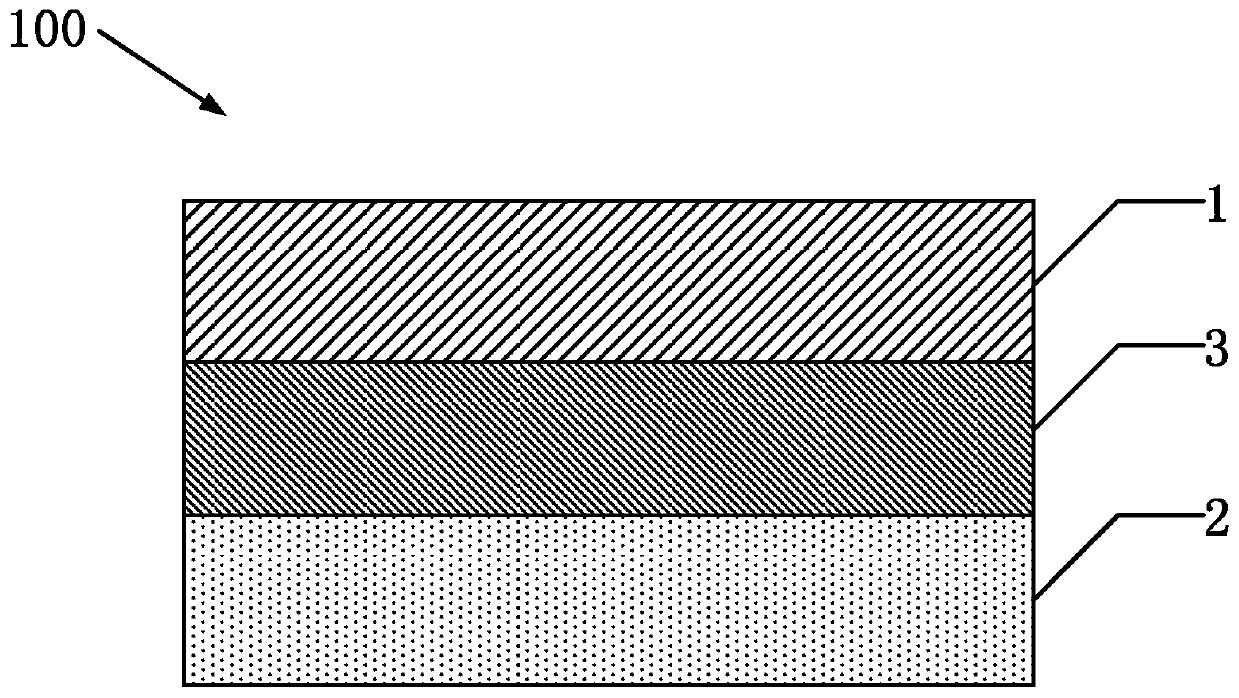

[0048] Such as figure 2 As shown, the display panel 100 of this embodiment includes: a metal layer 1 , a darkening layer 2 and a conductive layer 3 .

[0049] The material of the metal layer 1 includes: at least one of Cu, Mo, Ti, Al, Ni, Nb, Ta and Cr. Wherein the thickness of the metal layer is 200-700nm. Among them, 200 nm, 400 nm, and 600 nm are preferable. In this way, effects such as signal transmission can be achieved.

[0050] In fact, the display panel 100 includes a substrate and thin film transistors disposed on the substrate. The thin film transistor includes: an active layer, a gate insulating layer, a gate layer, an interlayer insulating layer, and a source-drain layer. The material of the gate layer and the source-drain layer is metal, so the metal layer 1 described in this embodiment is the gate layer and the source-drain layer in the thin film transistor.

[0051] The darkening layer 2 is disposed on one or both surfaces of the metal layer 1 , and in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com