A liquid metal series cooling cable

A liquid metal and cable technology, applied in the direction of insulated cables, liquid conductors, cooling/ventilation/heating transformation, etc., can solve the problems of poor cooling effect and low mechanical transmission efficiency, and achieve improved cooling efficiency, simple structure, and high flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

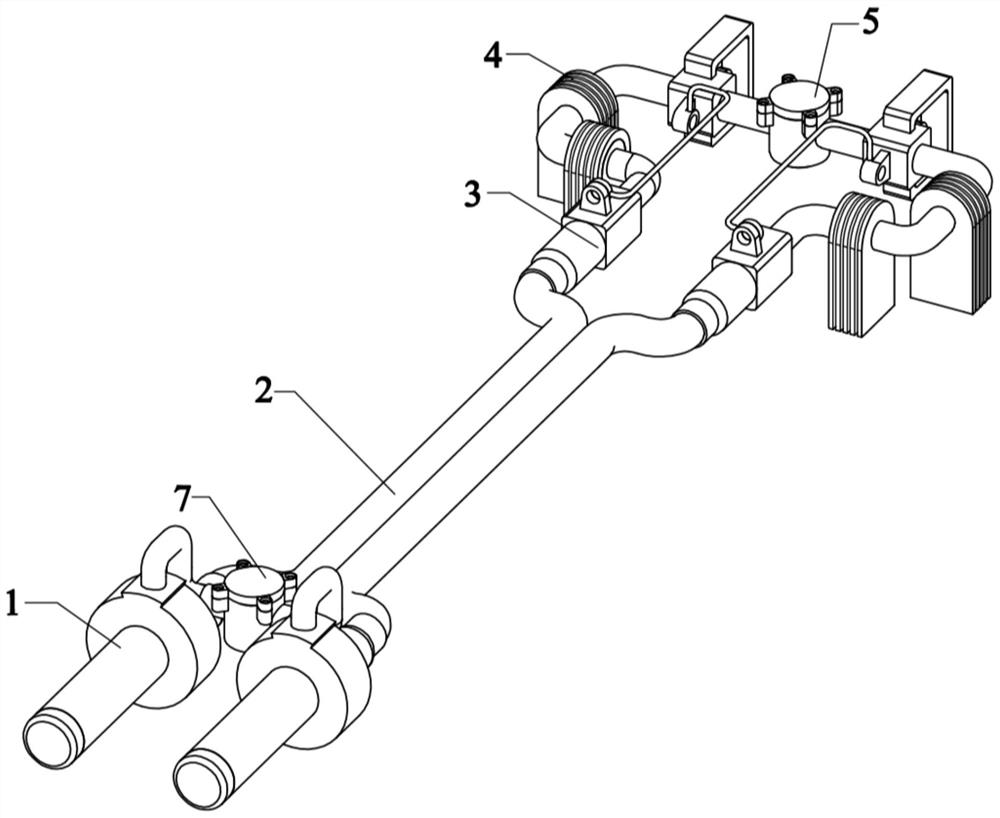

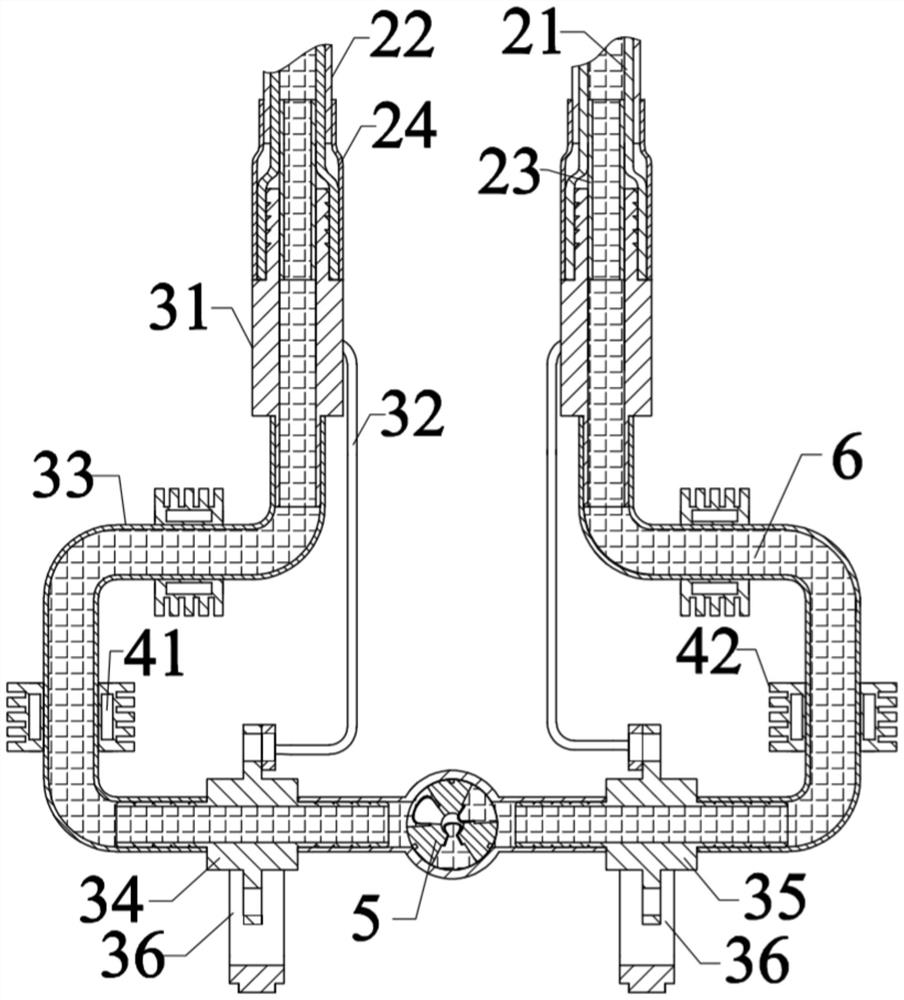

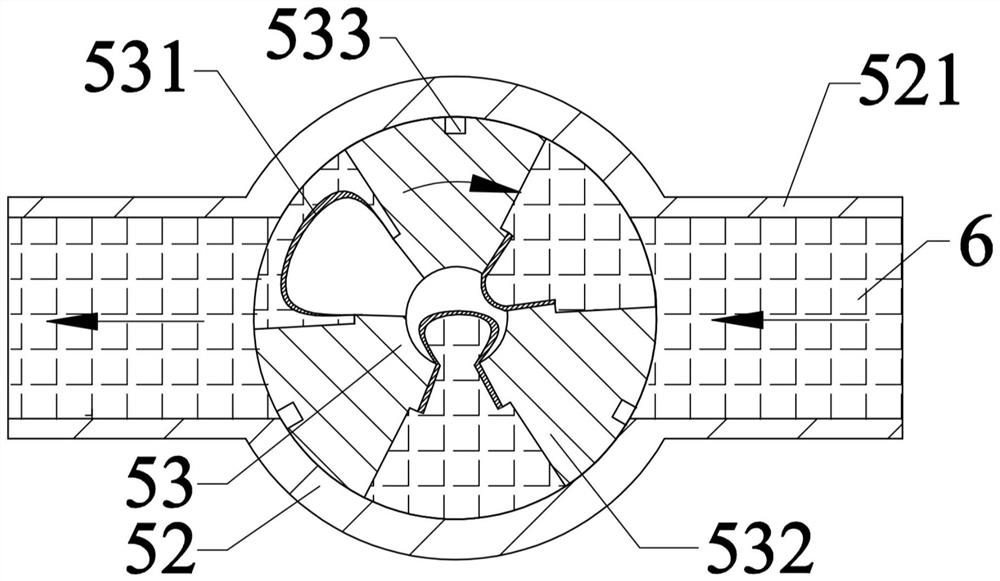

[0029] The invention provides a liquid metal series cooling cable (cable for short, see Figure 1-11 ), including a charging terminal assembly 1, a hollow cable 2 and a cooling assembly 4; it is characterized in that the cable also includes a shunt assembly 3, a first liquid-proof rotor assembly 5 and a second liquid-proof rotor assembly 7; the shunt assembly 3 includes Bare conductor 32, insulating tube 33, No. 1 conductive terminal 34, No. 2 conductive terminal 35, C-shaped electromagnet 36 and conductive shunt 31;

[0030] The No. 1 conductive terminal 34, the first liquid-isolated rotor assembly 5, the No. 2 conductive terminal 35 and the plurality of cooling assemblies 4 are all arranged on the insulating tube 33, and the No. 1 conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com