155-grade polyester enameled copper wire production process

A painting and frame technology, applied in the field of enameled wires, can solve the problems of affecting the painting efficiency of copper wires, long preparation time of copper wires, waste of paint, etc., and achieve the effects of easy replacement, improvement of efficiency, and reduction of waste of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

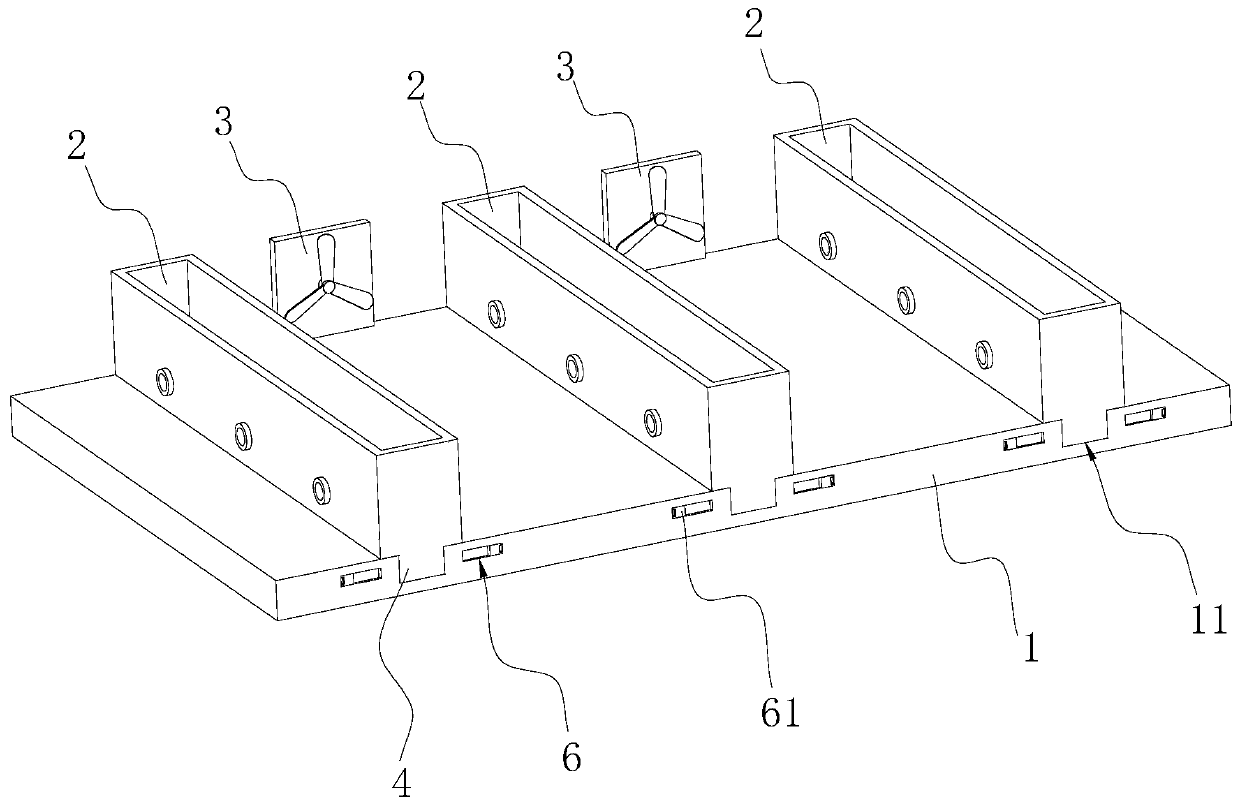

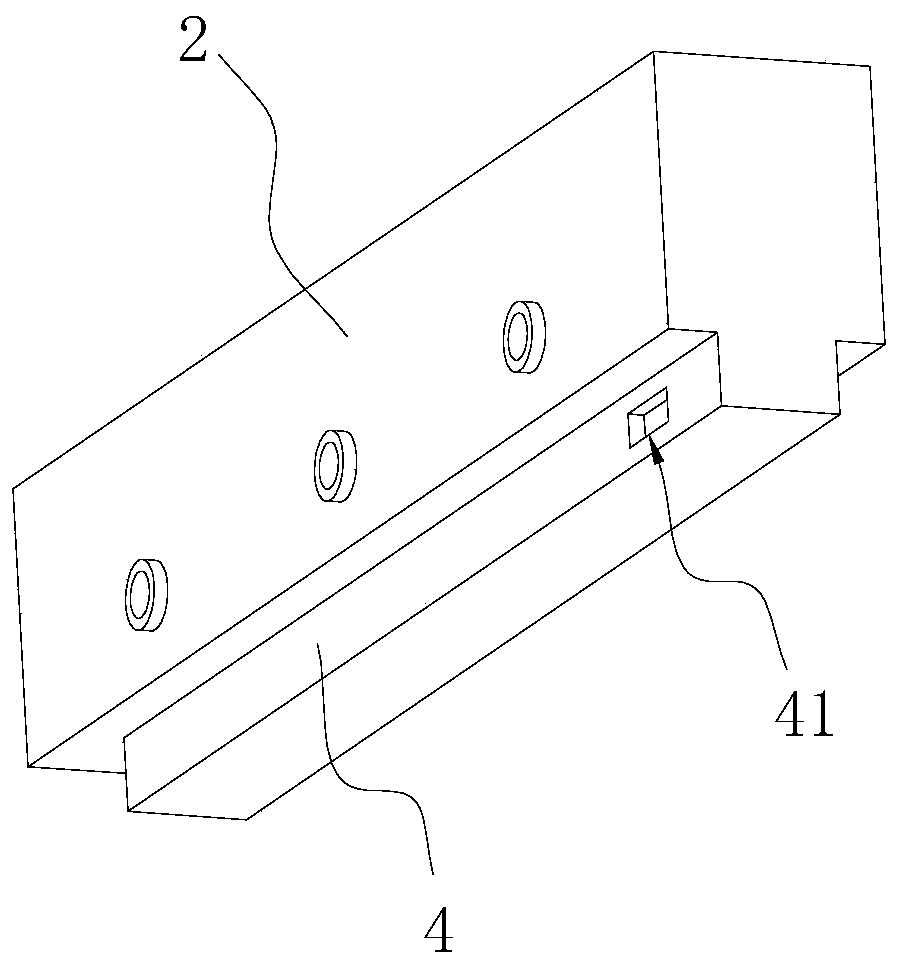

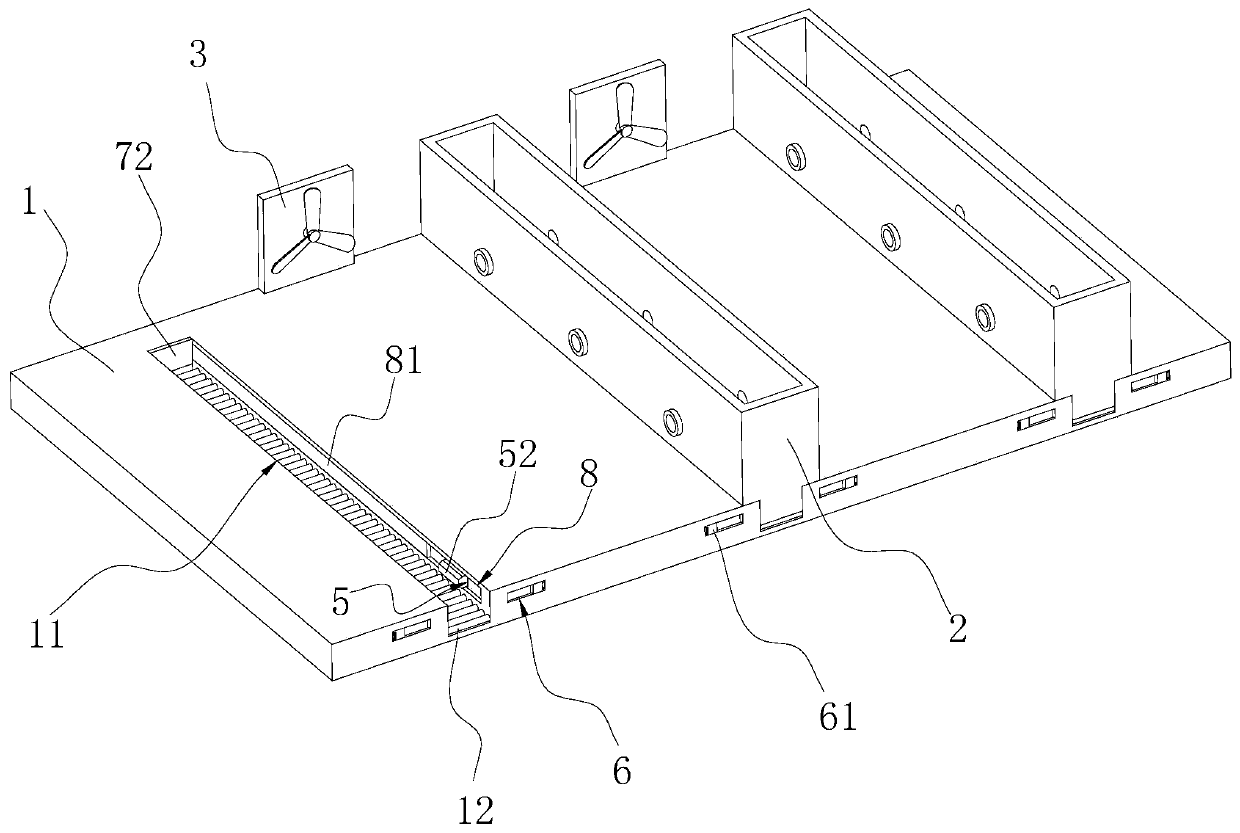

[0033] Such as figure 1 As shown, a kind of painting equipment comprises a frame 1 and a paint pool 2, the frame 1 is flat, and several paint pools 2 are arranged at intervals along the length direction of the frame 1, wherein the upper end of the frame 1 is set There is a chute 11, the chute 11 extends along the width direction of the frame 1 to penetrate the frame 1, and a sliding seat 4 is integrally provided at the lower end of the painting pool 2, the sliding seat 4 is a strip-shaped wedge block, and the sliding seat 4 slides Inserted in the chute 11, the detachable installation of the paint pool 2 on the frame 1 is realized. When actually changing the paint, the paint pool 2 is directly removed from the frame 1, and then the new paint The paint tank 2 is installed on the frame 1, and there is no need to replace the paint material in the paint tank 2, thereby improving the utilization rate of the paint material and the processing efficiency of wire painting.

[0034] And...

Embodiment 2

[0043] Production process of grade 155 polyester enamelled copper wire, including A. setting out and straightening; B. extruding round wire; C. extruding flat wire I; D. extruding flat wire II; E. extruding Flat wire manufacturing III; F. cooling; G. ultrasonic cleaning; H. annealing; I. cleaning and drying; paint equipment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap