Preparation method of transition metal-nitrogen-carbon nanotube co-doped activated carbon oxygen reduction catalyst

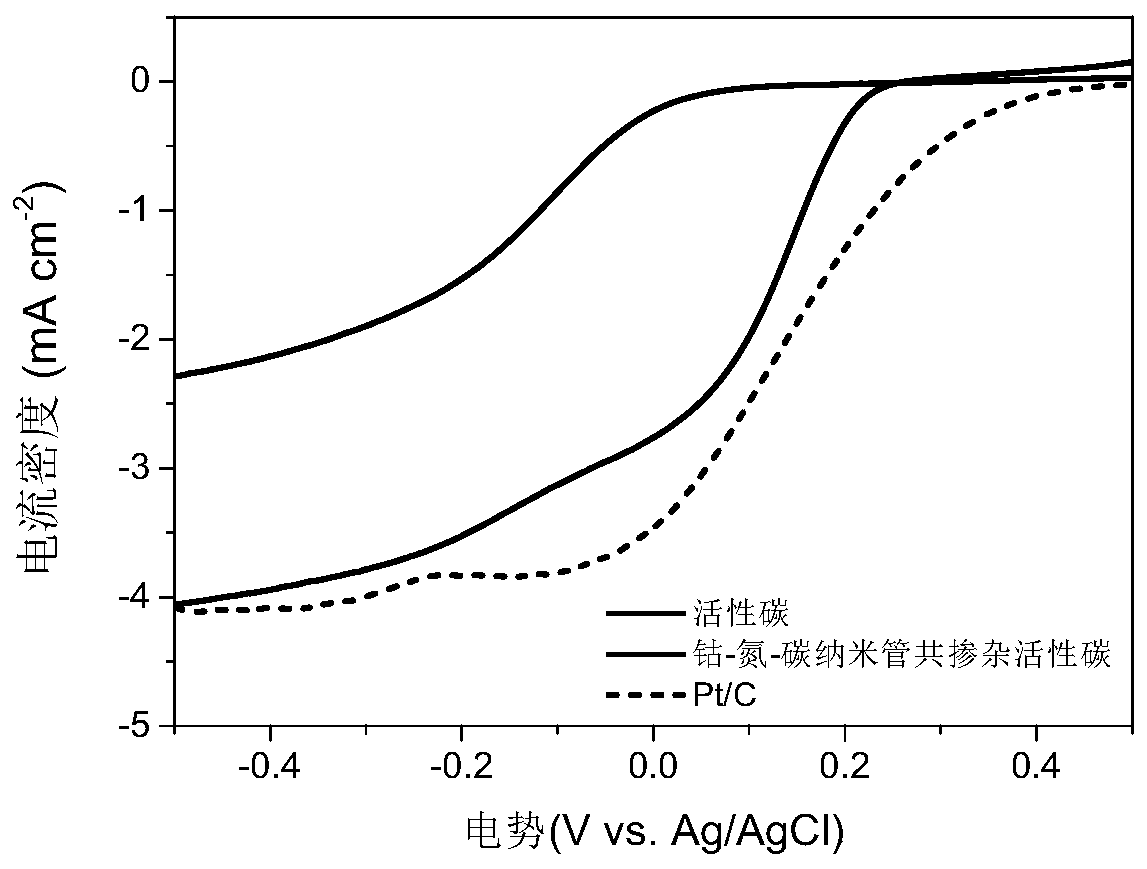

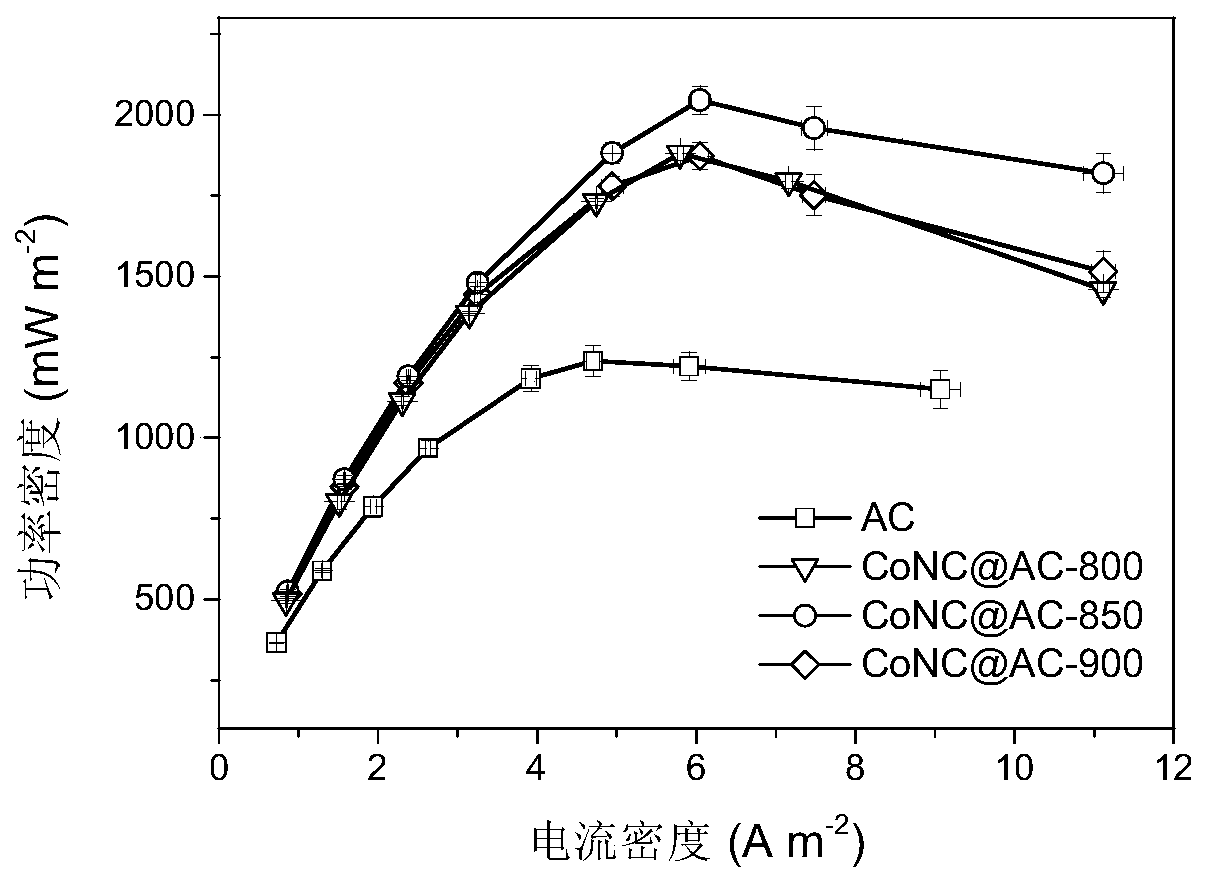

A technology of carbon nanotubes and transition metals, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of wide material sources, excellent oxygen catalytic reduction performance, and improved oxygen catalytic reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

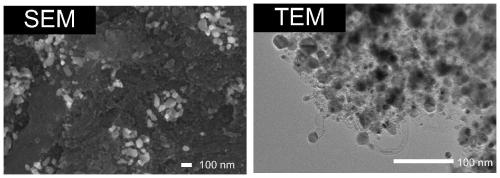

Image

Examples

Embodiment 1

[0024] A method for preparing cobalt-nitrogen-carbon nanotube co-doped active carbon oxygen reduction catalyst, said preparation method comprising the steps of:

[0025] ①Activated carbon carrier pretreatment: Soak the activated carbon in 5mol / L nitric acid solution for 12 hours, filter after soaking, wash the activated carbon with deionized water, remove the remaining nitric acid, and dry at 80°C;

[0026] ②In situ growth of CoZn-ZIF on activated carbon: 2.825mmol Co(NO 3 ) 2 ·6H 2 O and 2.825mmol Zn(NO 3 ) 2 ·6H 2 O was dissolved in 80mL methanol to form solution A; 45.07mmol 2-methylimidazole was dissolved in 80mL methanol to form solution B; 1.65g of the product obtained in step ① was added to solution B and stirred for 6h to form a mixed solution; solution A was added Stir and react in the mixture for 24 hours at 25°C. After the reaction, centrifuge to obtain the precipitate, wash it with methanol three times ultrasonically, and dry it in vacuum at 80°C;

[0027] ③H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com