Multi-pass continuous drawing method for medical stainless steel ultrafine wire

A technology of stainless steel and ultra-fine wire, applied in the direction of wire drawing dies, etc., can solve the problems of narrow application range of strength, poor finish, and low production efficiency, and achieve the elimination of internal stress and the precipitation of harmful carbides, uniform structure and composition, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0034]At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without ...

Embodiment 1

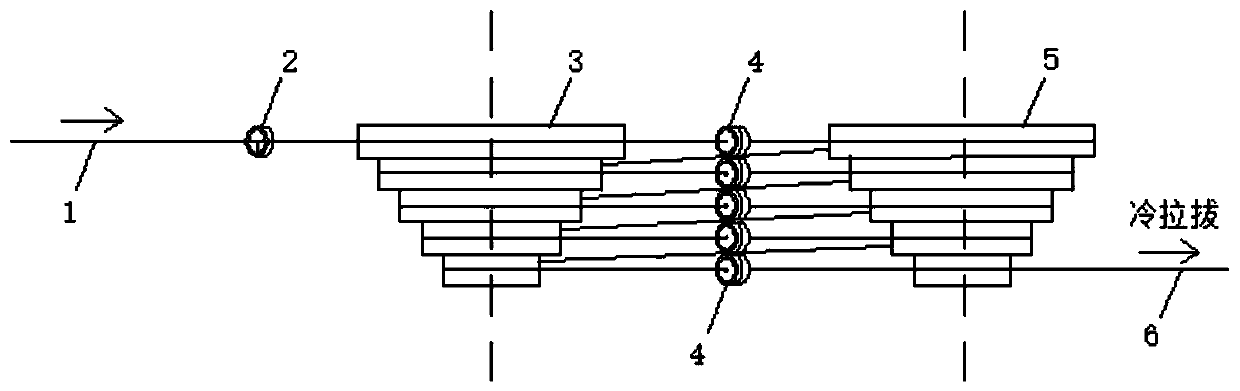

[0036] The invention discloses a multi-pass continuous drawing method for medical stainless steel ultrafine wire, which comprises the following steps:

[0037] Step 1) Coating the Ф0.8mm stainless steel filament billet;

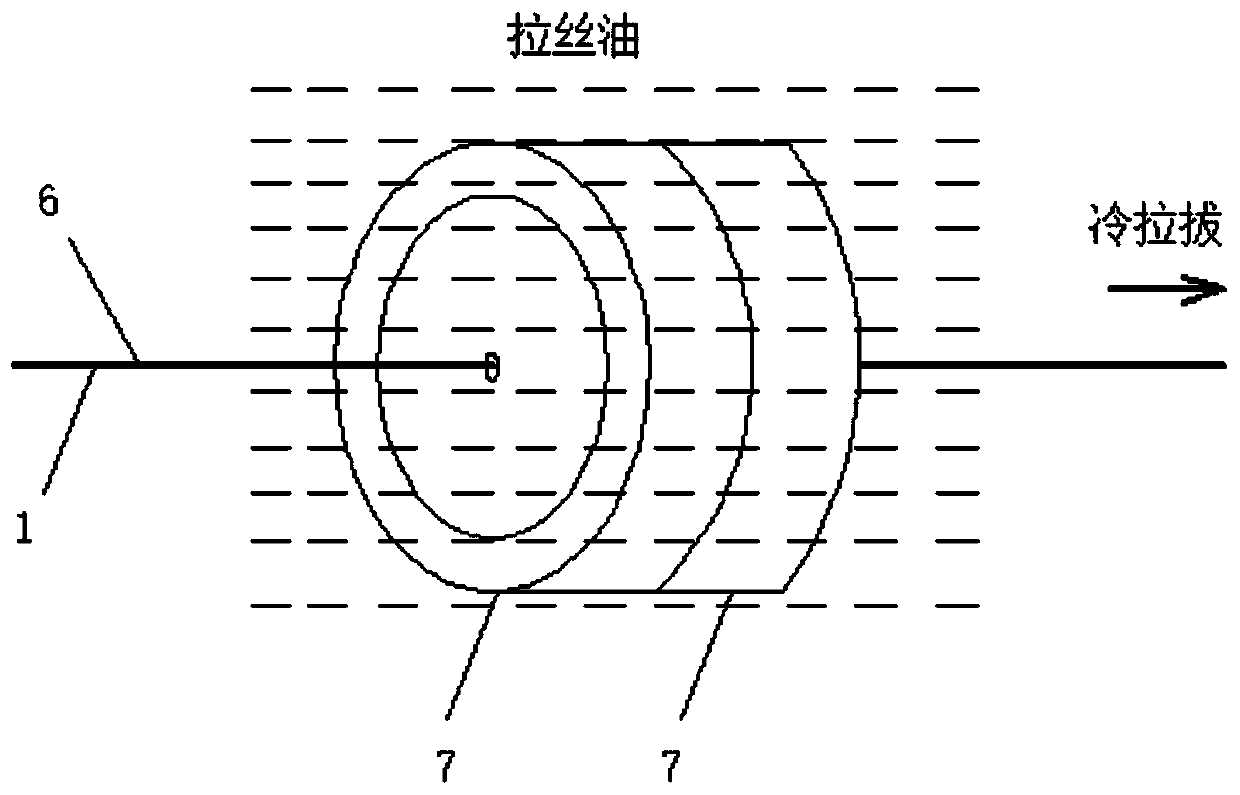

[0038] Step 2) performing a cold drawing on the stainless steel filament billets coated in step 1) to obtain ultra-fine stainless steel wires;

[0039] Step 3) performing on-line decoating treatment and on-line solid solution treatment on the stainless steel ultra-fine wire in step 2);

[0040] Step 4) performing secondary cold drawing and online degreasing treatment on the stainless steel ultra-fine wire that has undergone on-line decoating treatment and on-line solution treatment in step 3), to obtain a medical stainless steel ultra-fine wire with a bright surface.

Embodiment 2

[0042] The invention discloses a multi-pass continuous drawing method for medical stainless steel ultrafine wire, which comprises the following steps:

[0043] Step 1) Coating the Ф0.8mm stainless steel filament billet;

[0044] Step 2) performing a cold drawing on the stainless steel filament billets coated in step 1) to obtain ultra-fine stainless steel wires;

[0045] Step 3) performing on-line decoating treatment and on-line solid solution treatment on the stainless steel ultra-fine wire in step 2);

[0046] Step 4) performing secondary cold drawing and online degreasing treatment on the stainless steel ultra-fine wire that has undergone on-line decoating treatment and on-line solution treatment in step 3), to obtain a medical stainless steel ultra-fine wire with a bright surface.

[0047] Preferably, the coating treatment in step 1) is to coat the solid-solution stainless steel filament blank with a matte surface after alkali-acid washing treatment, and then coat the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com