Injection molding processing device

A technology of injection molding processing and transmission wheel, which is applied in the field of injection molding, can solve the problems of affecting the molding of molding materials, difficulty in opening molds, increasing friction, etc., and achieve the effect of avoiding mutual squeezing and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

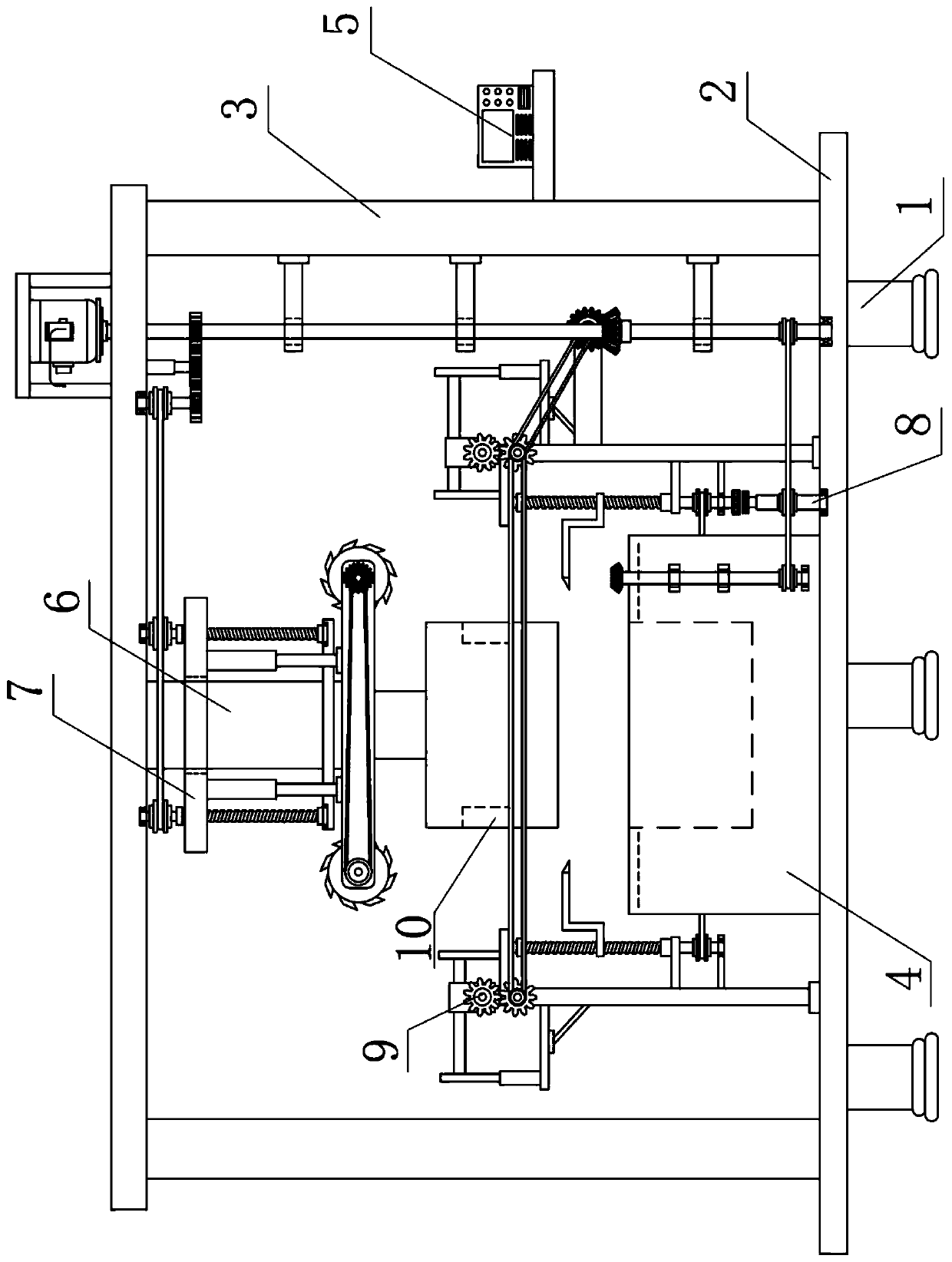

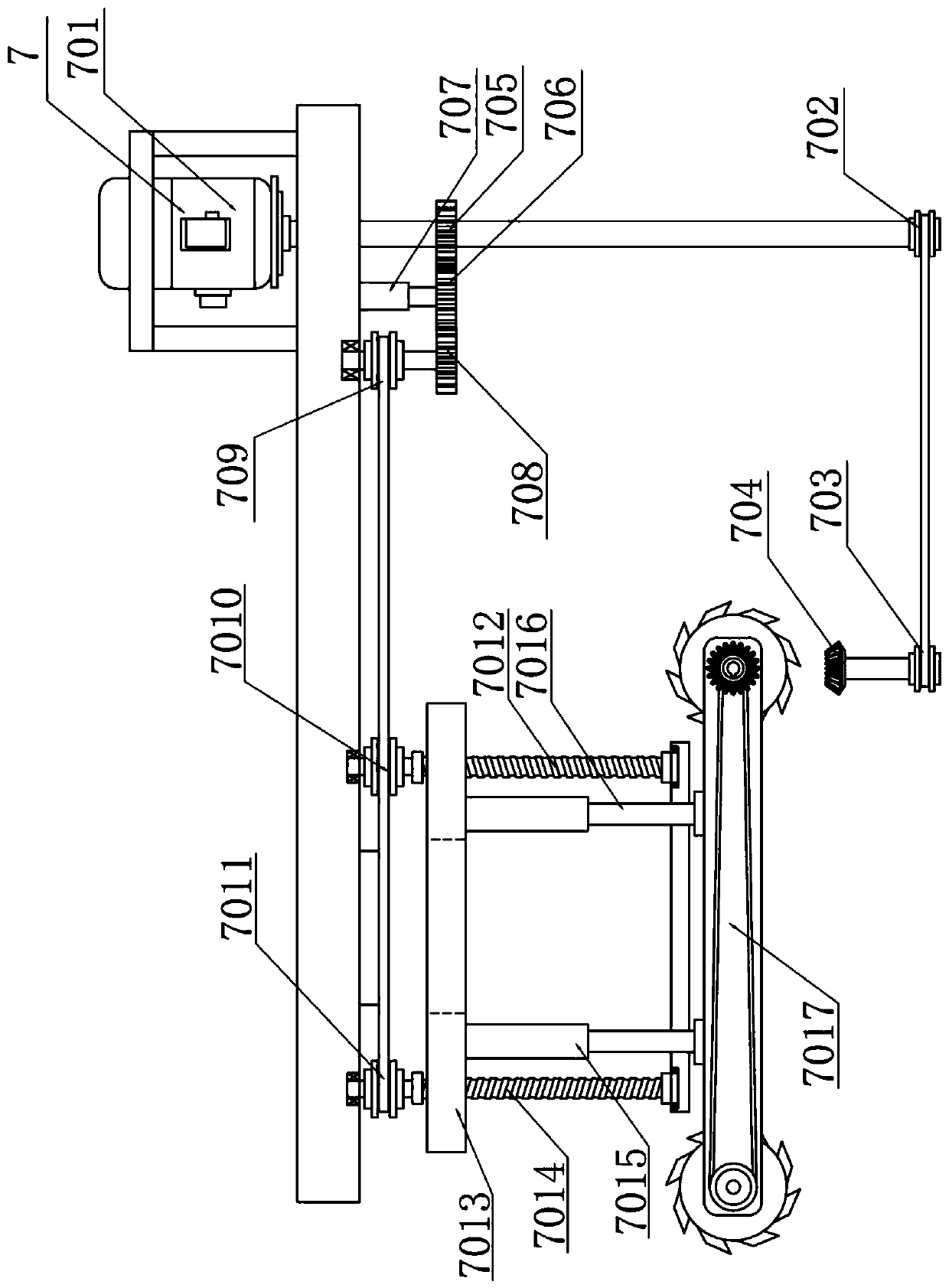

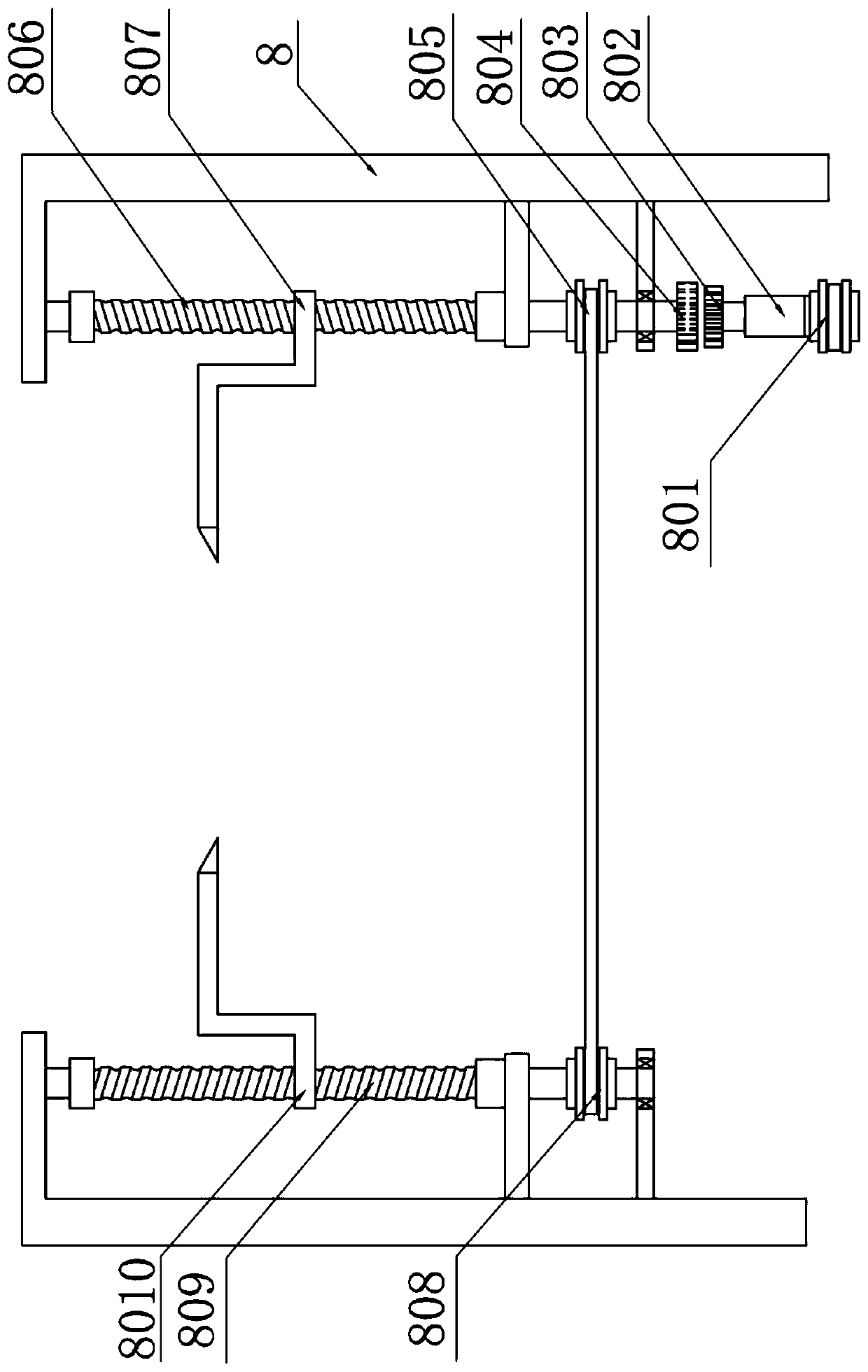

[0032] An injection molding processing device, such as Figure 1-8 As shown, it includes support foot 1, bottom plate 2, frame 3, mold 4, control panel 5, hydraulic rod 6, anti-wrinkle device 7, flat pressing device 8, overflow prevention auxiliary device 9 and molded block 10; the top of support foot 1 and bottom plate 2 The right side of the top of the bottom plate 2 is welded to the frame 3; the top middle of the bottom plate 2 is connected to the mold 4; the top middle right side of the bottom plate 2 is provided with a flat pressing device 8; The top middle part is connected with the hydraulic rod 6; the top middle part of the frame 3 is provided with an anti-wrinkle device 7, and the anti-wrinkle device 7 is located at the periphery of the hydraulic rod 6; the front right side of the mold 4 is connected with the anti-wrinkle device 7, and the anti-wrinkle device The right side of the inner bottom of 7 is connected with the flat pressing device 8; the bottom of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com